High temperature hydrogen sintering furnace

A sintering furnace and hydrogen technology, applied in furnaces, muffle furnaces, cooking furnaces and other directions, can solve the problems that high temperature hydrogen sintering furnaces are difficult to meet the requirements, and achieve the effects of good heat insulation effect, stable performance and fast heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

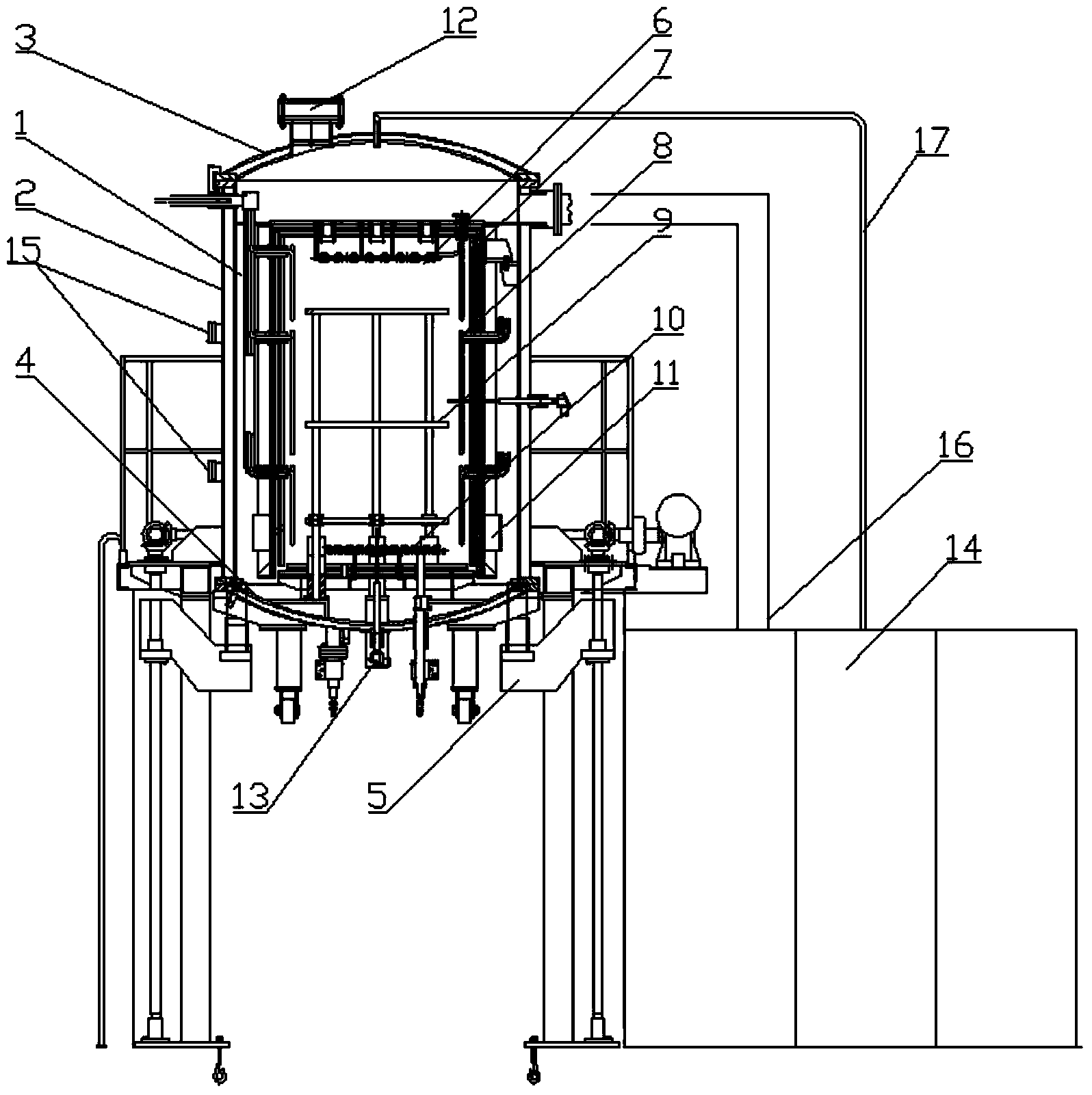

[0013] combined with figure 1 An embodiment of the present invention is described.

[0014] A high-temperature hydrogen sintering furnace, comprising a furnace 1, a furnace body 2, an electrical system 14 and a vacuum system 16, the furnace 1 is installed in the furnace body 2, the upper part of the furnace body 2 is fixed with an upper head 3 and the lower part has The lower head 4, and the upper head 3 are connected to the hydrogen pipeline 17, the lower head 4 is connected to the lifting system 5, and the lower head 4 is driven by the lifting system 5 to open and close the furnace body 2, and the upper part of the furnace body 2 passes through the connection port Connected with the vacuum system 16, the inner wall of the furnace 1 is hung with a reflective screen 7, an upper heating body 6, a side heating body 8 and a lower heating body 10, and the upper heating body 6, side heating body 8 and lower heating body 10) are located on the reflecting screen 7; the rack 9 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com