A composite textile printing and dyeing wastewater treatment process

A technology for textile printing and dyeing and wastewater treatment, which is applied in the field of textile printing and dyeing wastewater treatment, which can solve the problems of high operator requirements, high recycling rate, and high cost, and achieve the effects of simple wastewater treatment process, promotion of degradation, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

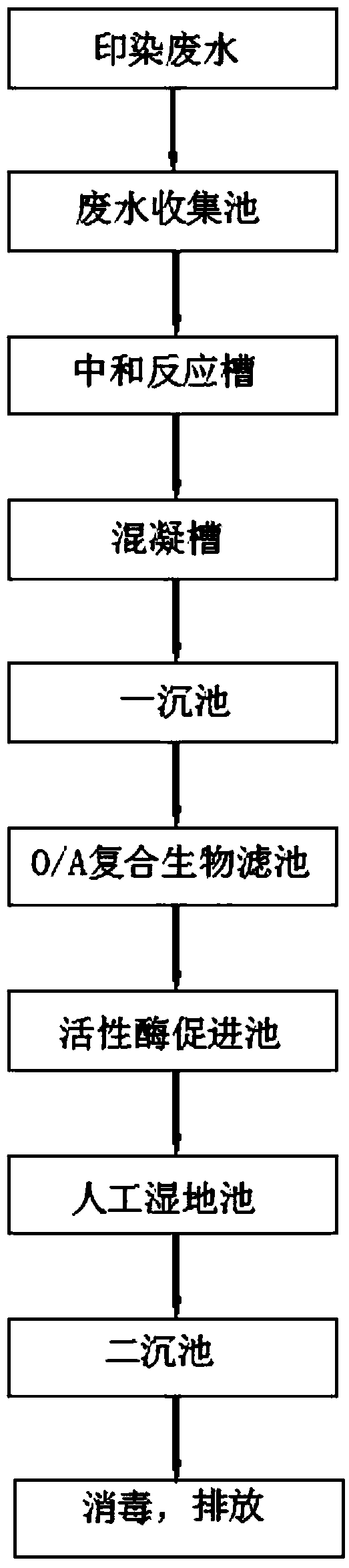

[0023] A composite textile printing and dyeing wastewater treatment process, comprising the steps of:

[0024] S1, neutralization: neutralize the textile printing and dyeing wastewater with dilute sulfuric acid to a pH of 6.5-8.0;

[0025] S2. Coagulation and precipitation: Put 1.5g / L coagulant into the coagulation tank, stir the tank at a rate of 50r / min for 30min, and let it settle for 1h;

[0026] S3, O / A composite biofilter filtration: Pass the waste liquid in the upper layer of the coagulation tank into the O / A composite biofilter, so that the organic pollutants and suspended particles in the sewage are adsorbed, retained and degraded by the microorganisms on the carrier, filter;

[0027] S4. Activation of the active enzyme promotion pool: put 6 mg / L of active enzyme Bacillus protease and magnesium chloride solution into the active enzyme promotion pool, stir the pool water for 2 hours, so that the organic matter in the sewage is adsorbed by the active enzyme on the surf...

Embodiment 2

[0031] A composite textile printing and dyeing wastewater treatment process, comprising the steps of:

[0032] S1, neutralization: neutralize the textile printing and dyeing wastewater with dilute sulfuric acid to a pH of 6.5-8.0;

[0033] S2. Coagulation and precipitation: put 3g / L coagulant into the coagulation tank, stir the tank at a rate of 30r / min for 20min, and let it settle for 2h;

[0034] S3, O / A composite biofilter filtration: Pass the waste liquid in the upper layer of the coagulation tank into the O / A composite biofilter, so that the organic pollutants and suspended particles in the sewage are adsorbed, retained and degraded by the microorganisms on the carrier, filter;

[0035] S4. Activation of the active enzyme promotion pool: put 2 mg / L of active enzyme Louis galactosidase and magnesium chloride solution into the active enzyme promotion pool, stir the pool water for 3 hours, so that the organic matter in the sewage is adsorbed by the active enzyme on the bact...

Embodiment 3

[0039] A composite textile printing and dyeing wastewater treatment process, comprising the steps of:

[0040] S1, neutralization: neutralize the textile printing and dyeing wastewater with dilute sulfuric acid to a pH of 6.5-8.0;

[0041] S2. Coagulation and precipitation: Put 0.5g / L coagulant into the coagulation tank, stir the tank at a rate of 80r / min for 10min, and let it settle for 0.5h;

[0042] S3, O / A composite biofilter filtration: Pass the waste liquid in the upper layer of the coagulation tank into the O / A composite biofilter, so that the organic pollutants and suspended particles in the sewage are adsorbed, retained and degraded by the microorganisms on the carrier, filter;

[0043] S4. Activation of active enzyme-promoting pool: put 8 mg / L of active enzyme cellulase and magnesium chloride solution into the active enzyme-promoting pool, stir the pool water to activate for 1 hour, so that the organic matter in the sewage is adsorbed by the active enzyme on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com