Coal mine-use ultra-high molecular weight polyethylene antistatic flame-retardant pipe material and preparation method thereof

An ultra-high molecular weight and polyethylene technology, which is applied in the field of ultra-high molecular weight polyethylene antistatic and flame retardant pipes for coal mines and their preparation, can solve the problems that the performance cannot meet the safety technical requirements for pipes used in underground coal mines, and achieves increased flame retardant properties. Antistatic function, smooth inner and outer walls, uniform plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

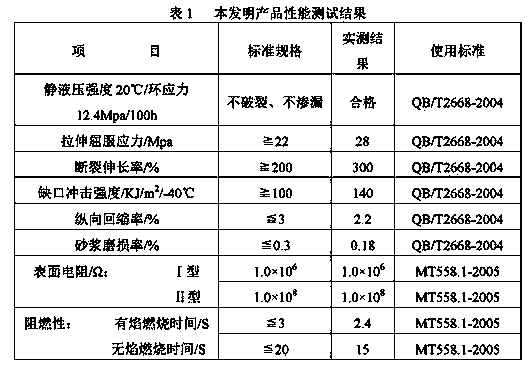

Examples

Embodiment 1

[0033] The ultra-high molecular weight polyethylene antistatic and flame-retardant pipe material for coal mines of the present invention is expressed in parts by weight, consisting of 60 parts of ultra-high molecular weight polyethylene UHMWPE, 7 parts of linear low-density polyethylene LLDPE, acrylonitrile-chlorinated polyethylene- 8 parts of styrene copolymer ACS, 2 parts of polymer wax (the polymer wax is PE-110D type polymer wax provided by Beijing Tianhengjian Technology Development Co., Ltd.), 10 parts of superconducting carbon black CB, 8 parts of red phosphorus, 10 parts of antimony trioxide, 28 parts of pretreated calcium sulfate whiskers, 2 parts of barium sulfate and 2 parts of titanate coupling agent NDZ-201.

[0034] The ultra-high molecular weight polyethylene UHMWPE used has a molecular weight of 2 to 10 million units.

[0035] Example 2:

Embodiment 2

[0037] The ultra-high molecular weight polyethylene antistatic and flame-retardant pipe material for coal mines of the present invention is expressed in parts by weight, consisting of 50 parts of ultra-high molecular weight polyethylene UHMWPE as raw materials, 5 parts of chlorinated polyethylene CPE, and acrylonitrile-butadiene-styrene copolymerization 6 parts of ABS, 1.5 parts of ethylene bisoleamide EBO, 8 parts of molybdenum disulfide, 10 parts of melamine cyanurate, 22 parts of pretreated calcium sulfate whiskers, 1.5 parts of calcium stearate and aluminate coupling Agent DL-411 1.5 parts made.

[0038] The ultra-high molecular weight polyethylene UHMWPE used has a molecular weight of 2 to 10 million units.

[0039] Example 3:

Embodiment 3

[0041] The ultra-high molecular weight polyethylene antistatic and flame-retardant pipe material for coal mines of the present invention is expressed in parts by weight, consisting of 70 parts of ultra-high molecular weight polyethylene UHMWPE, 5 parts of linear low-density polyethylene LLDPE, and 4 parts of chlorinated polyethylene CPE. 10 parts of styrene maleic anhydride copolymer SMA, 2.5 parts of butyl stearate, 12 parts of zinc oxide, 20 parts of antimony trioxide, 35 parts of pretreated calcium sulfate whiskers, 2.5 parts of kaolin and aluminate coupling agent ASA 2.5 servings made.

[0042] The ultra-high molecular weight polyethylene UHMWPE used has a molecular weight of 2 to 10 million units.

[0043] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com