A kind of multi-component tire tread rubber and preparation method thereof

A tire tread and multi-component technology, applied in the field of rubber tire preparation, can solve limited problems and achieve the effects of simple process, low rolling resistance, dynamic heat generation and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

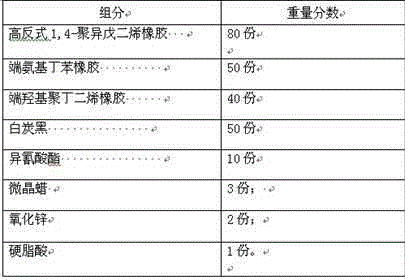

Method used

Image

Examples

Embodiment 1

[0033] (1) Under the protection of inert gas, add 50 g of the reaction system to the reaction system in turn, a positive lithium cause of a positive lithium lithium of 0.3g0.6 mol / L, and the reaction of 30 ° C for 4h.Cleaning and precipitation, it is necessary to highly transmitted 1,4-polyphonohne gelcin;

[0034] (2) Under the protection of inert gas, add 30g tetrahydrous furaku solvent to the reaction system in turn, 0.2g of lithium cither in a 0.2g of lithium lithium, and after -40 ° C for 2h, add 0.35g ethylene oxide to seal the end.After adding 10g of ethanol to clean the precipitation, the hydroxyl polyteadne gel lathes;

[0035] (3) Under the protection of inert gas, add 40g tetrahydrous solvent, 15g styrene, 20g butadiene monomer and 0.02g0.6mol / L positive butyl lithium cause to the reaction system.Add 1.45g4, 4'-tetramel amin aminotomylxylbhenyl ketone for sealing end, and then add excessive ethanol to clean and precipitate, and the end amino-butadhen benzene pill gel la...

Embodiment 2

[0041] (1) Under the protection of inert gases, add 60g cycanane, 30g isoprene monomer and 0.2g1.5mol / L to the reaction system in turn.Cleaning and precipitation, it is necessary to highly transmitted 1,4-polyphonohne gelcin;

[0042] (2) Under the protection of inert gases, add 40g tetrahydrofuxu solvents to the reaction system in turn, 0.3g of lithium cither a 0.3g of lithium lithium reaction to the reaction of 3h, and add 0.3g ethylene oxide to the end after -20 ° C.After adding 15g of ethanol to clean the precipitation, the hydroxyl polyteadne gel lathes;

[0043] (3) Under the protection of inert gas, add 50G tetrahydrous fuzid solvent, 25g styrene, 20g butadiene monomer and 0.02g1.5mol / L positive butyl lithium cause in turn.Add 1.50g4, 4′-tetramethyl dilate diodes to seal the end, and then add excessive ethanol to clean and precipitate.

[0044] (4) Add (1), (2), (3) the products of the income to high -speed hybrid, and add isocyanate, white charcoal black and other additive...

Embodiment 3

[0049] (1) Under the protection of inert gas, add 50 g of the reaction system to the reaction system, a positive lithium cause of a positive lithium lithium of 0.1g2.0mol / L in the reaction system, and the reaction of 50 ° C for 2h.Cleaning and precipitation, it is necessary to highly transmitted 1,4-polyphonohne gelcin;

[0050](2) Under the protection of inert gases, add 40g tetrahydrofuxu solvents to the reaction system, 0.4g of lithium lithium cause agent at 0.4g of lithium lithium, and after 4h at 0 ° C, add 0.4g ethylene oxide to seal the end.Add 15 g of ethanol to clean and precipitate, and the hydroxyl polyteadne gel lathes;

[0051] (3) Under the protection of inert gas, add 50G tetrahydrous furaky solvent, 30g styrene, 30g butadiene monomer and 0.01g2.0mol / L positive lithium cause to the reaction system.Add 2.15g4, 4′-tetramel aminotenols for sealing, and then add excessive ethanol to clean and precipitate.

[0052] (4) Add (1), (2), (3) the products of the income to high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com