Polishing method of buttons

A button and chemical polishing technology, which is applied in the direction of polishing composition, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problem of low polishing efficiency of drum polishing machine, easy rounding of button sharp corners, large consumption of tap water, etc. Problems, achieve the effect of reducing labor cost and labor intensity, stable polishing effect and high polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

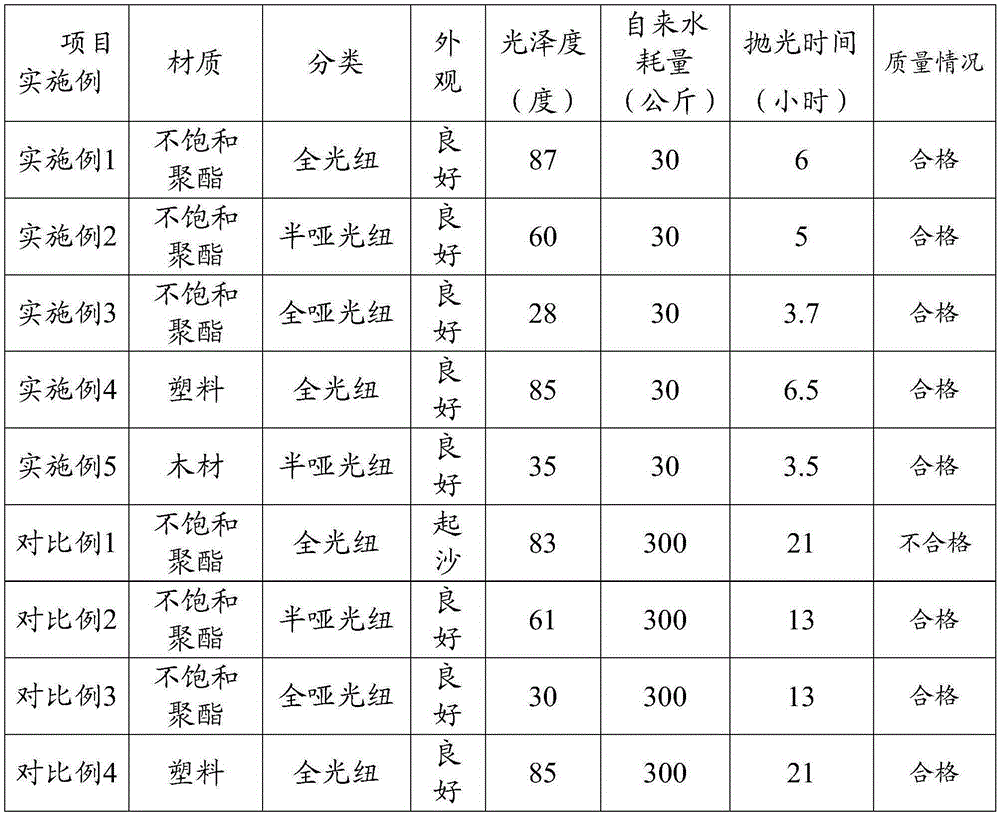

Examples

Embodiment 1

[0050]A method for polishing a full-gloss button with a glossiness greater than 80 degrees, comprising the steps of:

[0051] (1) Put 30 kg in the duplex eddy current polishing machine, the size is 2.5*8.0mm high-frequency ceramic particles, 5 kg of unsaturated polyester buttons to be polished, 1.8 kg of silica sand powder with a particle size of 300-400 mesh, start the machine and mix the above materials, and inject an appropriate amount of circulating water or Tap water immerses the above-mentioned materials until the unsaturated resin buttons and polishing abrasives flow under the action of water, stop the machine, control the water level at a position 1-3 cm higher than the materials, add 0.5 kg, and the chemical polishing agent mainly consists of the following weight Raw material composition in percent: carnauba wax emulsion 80wt%, DC-545wt% and sodium stearate 15wt%;

[0052] (2) Set the first polishing time for 5 hours, and the speed of the double vortex polishing mac...

Embodiment 2

[0056] A method for polishing a semi-matt button with a glossiness of 30-80 degrees, comprising the steps of:

[0057] (1) Put 30 kg of high-frequency ceramic particles with a size of 3*3mm, 6 kg of unsaturated polyester buttons and 1 kg of 150-300 mesh silica sand powder into the double-connected eddy current polishing machine in sequence. Turn on the machine to mix the above materials, and at the same time inject an appropriate amount of circulating water or tap water into the double vortex machine to immerse the above materials, so that the unsaturated resin buttons and polishing abrasives can flow under the action of water, stop the machine, and control the water level to be higher than the polishing materials 0.3 kg of chemical polishing agent is added at the position of 1-3 cm. The chemical polishing agent is mainly composed of the following raw materials in weight percentage: WE-215A 80wt%, DC-515wt% and sodium stearate 15wt%;

[0058] (2) Set the time for the first pol...

Embodiment 3

[0062] A method for polishing a fully matte button with a glossiness of less than 30 degrees, comprising the steps of:

[0063] (1) Put 20 kg of high-frequency ceramic particles with a size of 3*3mm, 10 kg of unsaturated polyester and 0.5 kg of 150-300 mesh silica sand powder into the double-link eddy current polishing machine in sequence. Start the machine to mix the above-mentioned materials, and at the same time inject an appropriate amount of circulating water or tap water into the duplex vortex machine to immerse the above-mentioned materials, so that the unsaturated resin buttons and polishing abrasives can flow under the action of water. Stop the machine, control the water level at a position 1-3 cm higher than the polishing material, add 0.2 kg of chemical polishing agent, and the chemical polishing agent is mainly composed of the following raw materials in weight percentage: WE-215A 80wt%, DC-515wt% and stearic acid Sodium 15wt%;

[0064] (2) Set the time for the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com