Lead-free cement-based piezoelectric composite material and preparation method thereof

A piezoelectric composite material and composite material technology are applied in the field of environment-friendly and high-efficiency cement-based piezoelectric composite materials and their preparation, which can solve the problems of unsuitability for use, failure to meet environmental protection requirements, damage to human beings and ecological environment, and the like, and achieve cost Low, excellent piezoelectric properties and polarization efficiency, effects of excellent piezoelectric and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

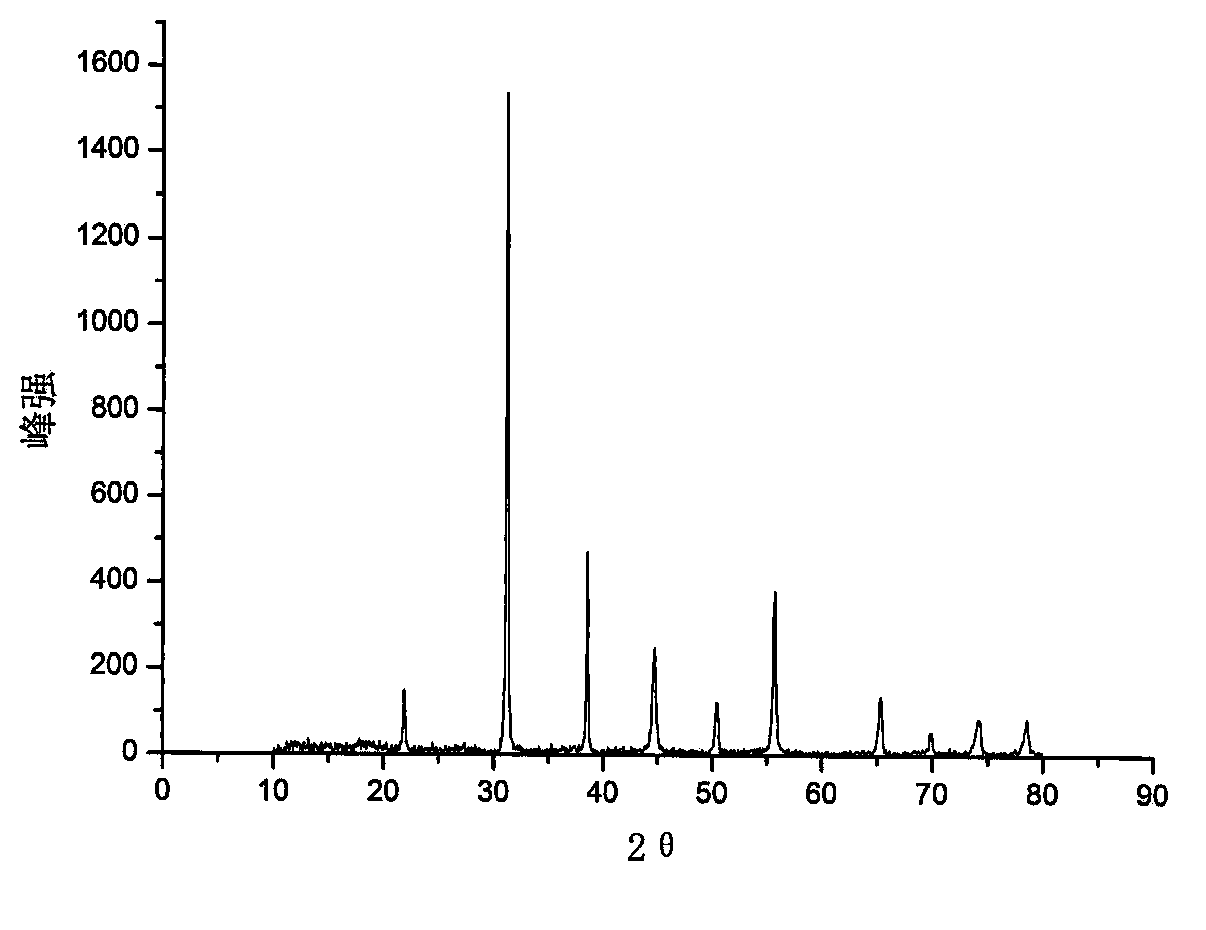

Method used

Image

Examples

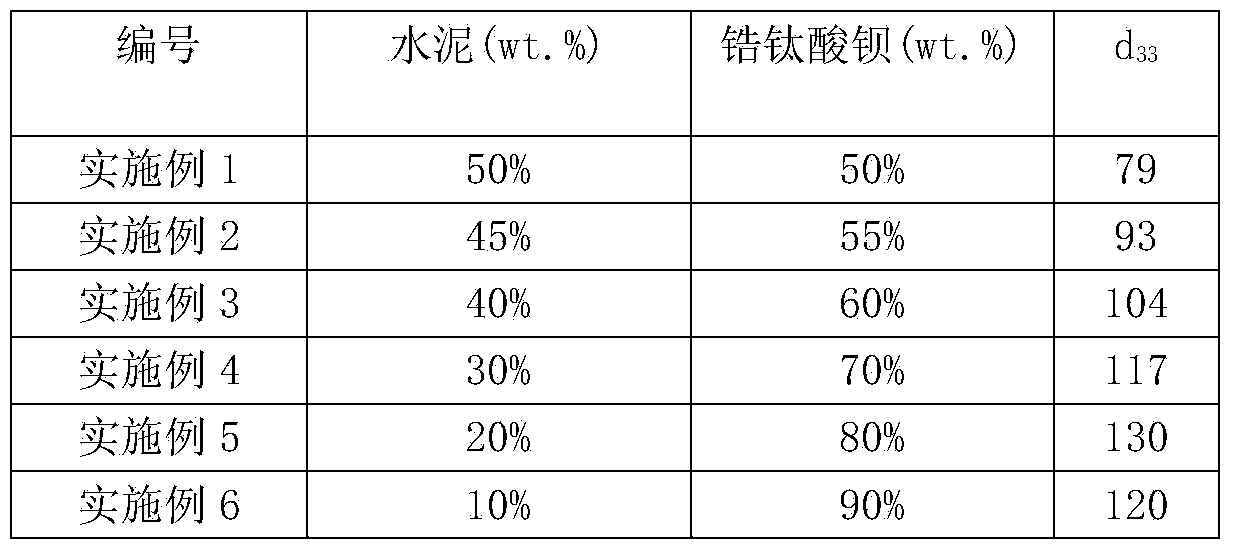

Embodiment 1

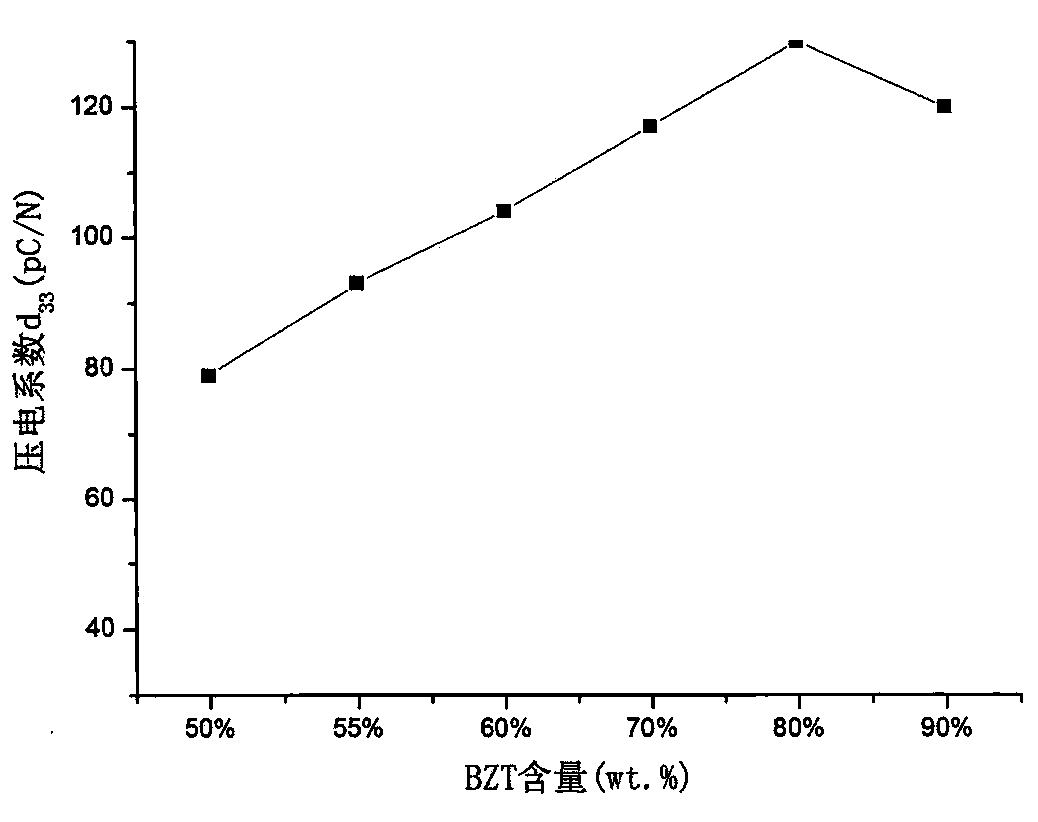

[0016] a. Mix 50% of pure-phase barium zirconate titanate ceramic particles and 50% of ordinary portland cement according to the mass percentage, using absolute ethanol as the medium, and ball milling, the ball milling time is 30min, after drying, sieve to obtain the mixture, and set aside;

[0017] b. Add water to the obtained mixture. The amount of water added is 15% of the weight of the cement. After fully stirring, it is pressed into a 10mm×1mm disc by a conventional compression molding method, and the molding pressure is 100MPa. Steam in the curing box Heat curing, the temperature is 80°C, 100%RH, after 2 days, scrub the surface with acetone, then evenly coat the non-burning electrodes on both sides of the pressed sheet, dry in a drying oven for 2 hours, and the drying temperature is 80°C, Then conduct polarization in silicone oil, the polarization field strength is 1.5kv / mm, the polarization temperature is 40°C, and the polarization time is 40min, the lead-free cement-bas...

Embodiment 2

[0019] a. Mix 55% of pure-phase barium zirconate titanate ceramic particles and 45% of ordinary portland cement according to the mass percentage, and use absolute ethanol as the medium, mix them by ball milling, the ball milling time is 35min, and sieve after drying to obtain the mixture, which is set aside;

[0020] b. Add water to the obtained mixture. The amount of water added is 20% of the weight of the cement. After fully stirring, it is pressed into a disc of 10mm×1mm by conventional compression molding method. The molding pressure is 105MPa, and steam is carried out in the curing box. Heat curing, the temperature is 80°C, 100%RH, after 2 days, scrub the surface with acetone, then evenly coat the non-burning electrodes on both sides of the pressed sheet, dry in a drying oven for 3 hours, and the drying temperature is 85°C, Then conduct polarization in silicone oil, the polarization field intensity is 2.0kv / mm, the polarization temperature is 45°C, and the polarization tim...

Embodiment 3

[0022] a. Mix 60% of pure-phase barium zirconate titanate ceramic particles and 40% of ordinary portland cement according to the mass percentage, and use absolute ethanol as the medium, mix them by ball milling, the ball milling time is 40min, and sieve after drying to obtain the mixture, which is set aside;

[0023] b. Add water to the obtained mixture. The amount of water added is 25% of the weight of the cement. After fully stirring, it is pressed into a disc of 10mm×1mm by a conventional compression molding method, and the molding pressure is 110MPa. Steam in the curing box Heat curing, the temperature is 80°C, 100%RH, after 2 days, scrub the surface with acetone, then evenly coat the non-burning electrodes on both sides of the pressed sheet, dry in a drying oven for 2.5h, and the drying temperature is 90°C , and then conduct polarization in silicone oil, the polarization field strength is 2.5kv / mm, the polarization temperature is 55°C, and the polarization time is 45min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com