Material with excellent piezoelectric property and preparation method of material

A piezoelectric performance, excellent technology, applied in the field of piezoelectric ceramics, can solve problems such as not having piezoelectric performance, and achieve the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

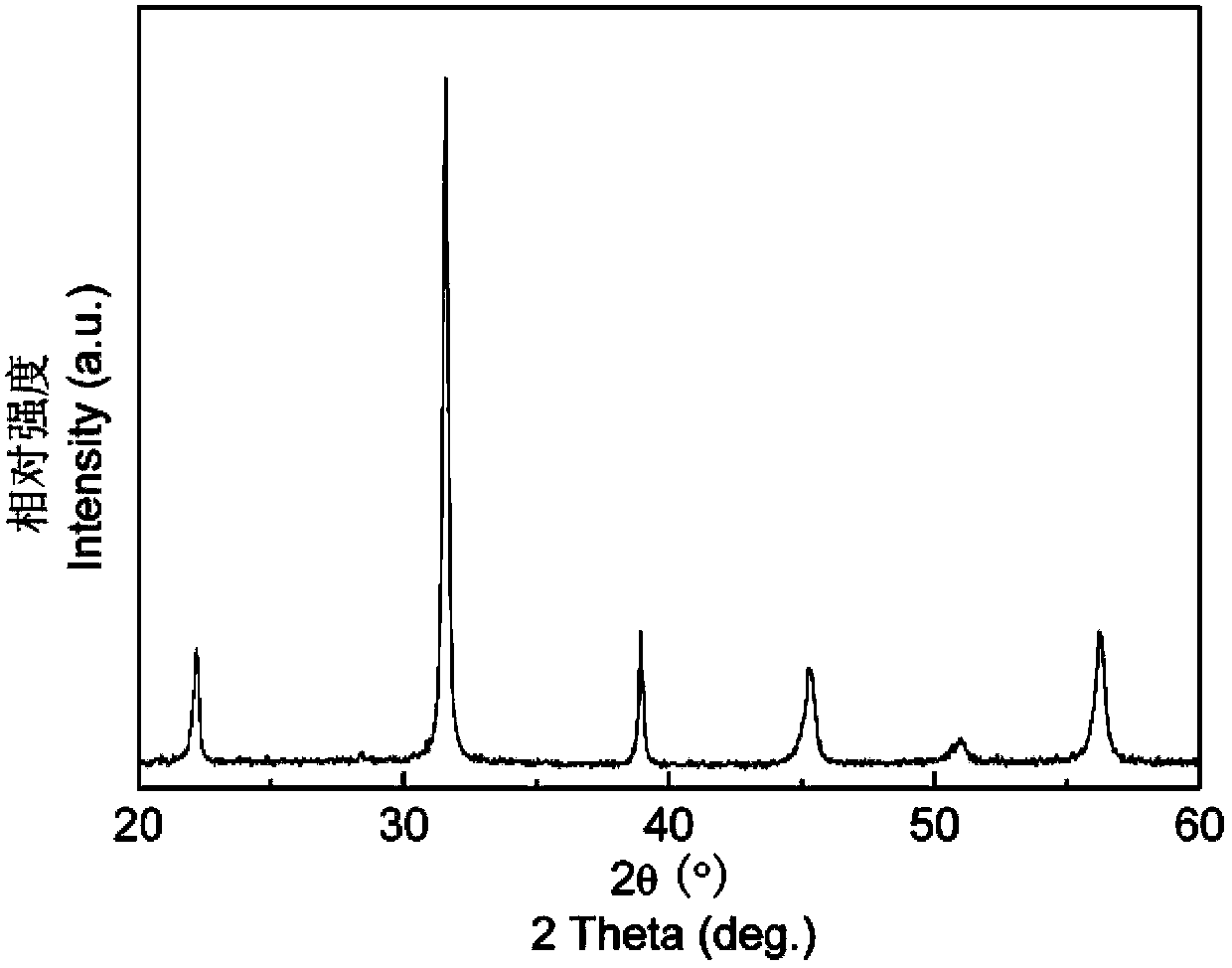

[0030] Utilize this invention to prepare 0.38Bi(Ni 1 / 2 f 1 / 2 )O 3 -0.62PbTiO 3 . Weigh 5.0000 g PbO, 3.1986 g Bi 2 o 3 , 0.5127 g NiO, 1.7890 g TiO 2 and 1.4449 g HfO 2 . Grind the powder thoroughly in a mortar, then calcinate the powder at 850°C for 6 hours, press the sample after cooling to room temperature with the furnace, and sinter the obtained sheet at 1180°C for 2 hours to obtain a dense high-pressure powder. Electrical properties of ceramic samples, piezoelectric coefficient d 33 =446pC / N, Curie temperature T C =290°C. figure 1 and figure 2 is 0.38Bi(Ni 1 / 2 f 1 / 2 )O 3 -0.62PbTiO 3 X-ray diffraction pattern and scanning electron microscope diffraction pattern.

Embodiment 2

[0032] Using this invention to prepare 0.39Bi(Ni 1 / 2 f 1 / 2 )O 3 -0.61PbTiO 3 . Weigh 5.0000 g PbO, 3.3366 g Bi 2 o 3 , 0.5349 g NiO, 1.7890 g TiO 2 and 1.5073 g HfO 2 . Fully grind to 1800 mesh in a mortar, then calcinate the powder at 850°C for 6 hours, press the sample after cooling to room temperature with the furnace, and finally sinter the obtained tablet at 1210°C for 2 hours, you can get Ceramic sheet samples with high piezoelectric properties, piezoelectric coefficient d 33 =434pC / N, Curie temperature T C =275°C. image 3 is 0.39Bi(Ni 1 / 2 f 1 / 2 )O 3 -0.61PbTiO 3 The x-ray diffraction pattern of .

Embodiment 3

[0034] Utilize this invention to prepare 0.30Bi(Ni 1 / 2 f 1 / 2 )O 3 -0.70PbTiO 3 . Weigh 5.0000 g PbO, 2.2366 g Bi 2 o 3 , 0.3585 g NiO, 1.7890 g TiO 2 and 1.0104 g HfO 2 . Grind the powder thoroughly in a mortar, then calcinate the powder at 600°C for 10 hours, press the sample after cooling to room temperature with the furnace, and sinter the obtained sheet at 1500°C for 1 hour to obtain a dense high-pressure powder. Electrical properties of ceramic samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com