Transparent silicone rubber reciprocating two-stage mixing extruder complete set of equipment

A technology of mixing extrusion and complete sets of equipment, which is applied in the field of complete sets of equipment for transparent silicone rubber reciprocating double-stage mixing and extruding machines. It can solve problems such as being easily suspended in the air, difficult to meet process requirements, and dust pollution. Improve the effect of mixing and dispersing, improve the degree of automation, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

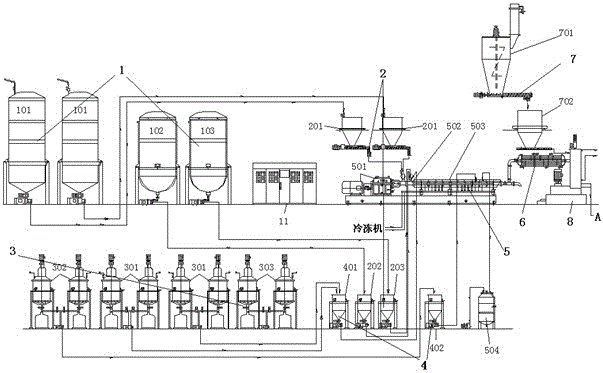

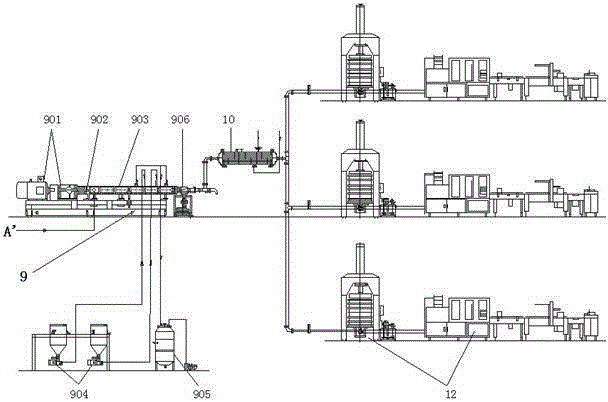

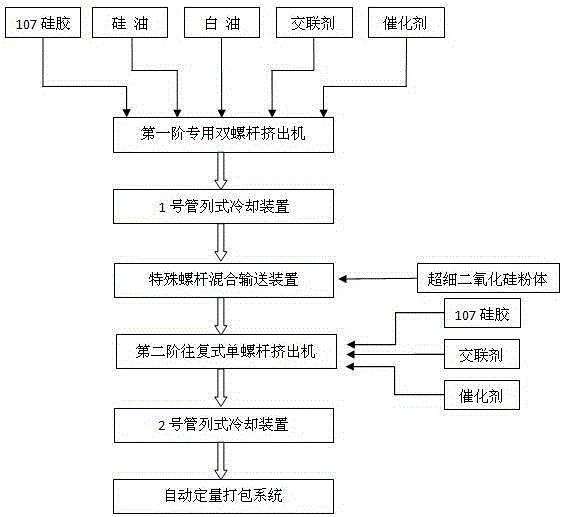

[0045] Such as figure 1 and figure 2 As shown, it is a set of equipment for a transparent silicone rubber reciprocating two-stage mixing extruder, wherein figure 1 A with figure 2 A’ in the A’ is connected, and the actual production is an integrated production line. Due to the length is too long, it is divided into figure 1 and figure 2 Two drawings, including liquid raw material automatic supply system 1, liquid raw material metering feeding system 2, liquid additive automatic supply system 3, liquid additive metering feeding system 4, first-stage twin-screw extruder unit 5, No. 1 tubular cooling device 6, powder supply metering system 7, screw mixing conveying device 8, second-stage reciprocating single-screw extruder 9, No. 2 tubular cooling device 10, PLC electrical control system 11, full Automatic quantitative packing and boxing system 12; the liquid raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com