Adhesive composition and optical film using the same

A technology of optical film and adhesive layer, which is applied in the field of optical film, can solve the problems of process corrosion, insufficient bonding, and inability to guarantee the bonding strength, etc., and achieve the effect of excellent bonding performance and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

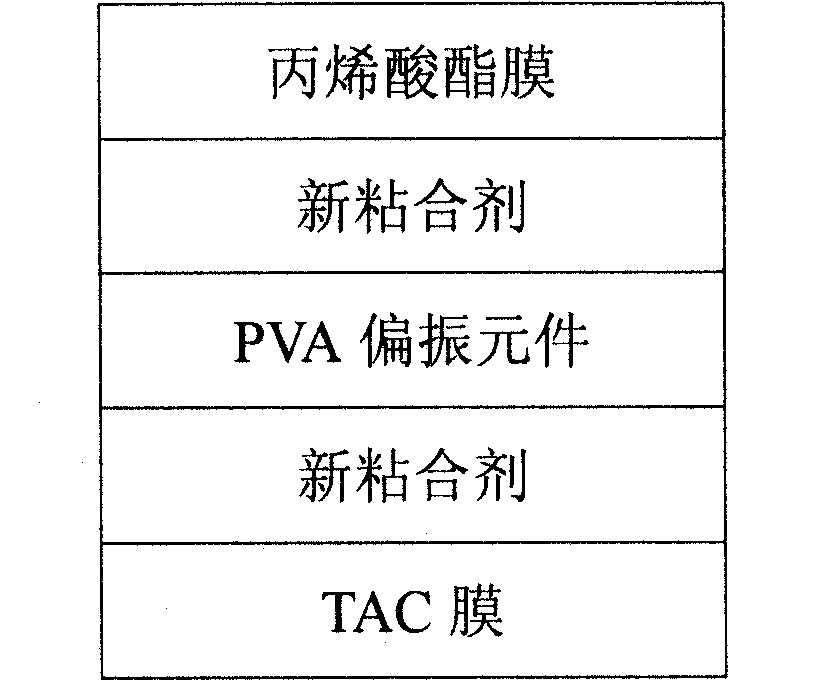

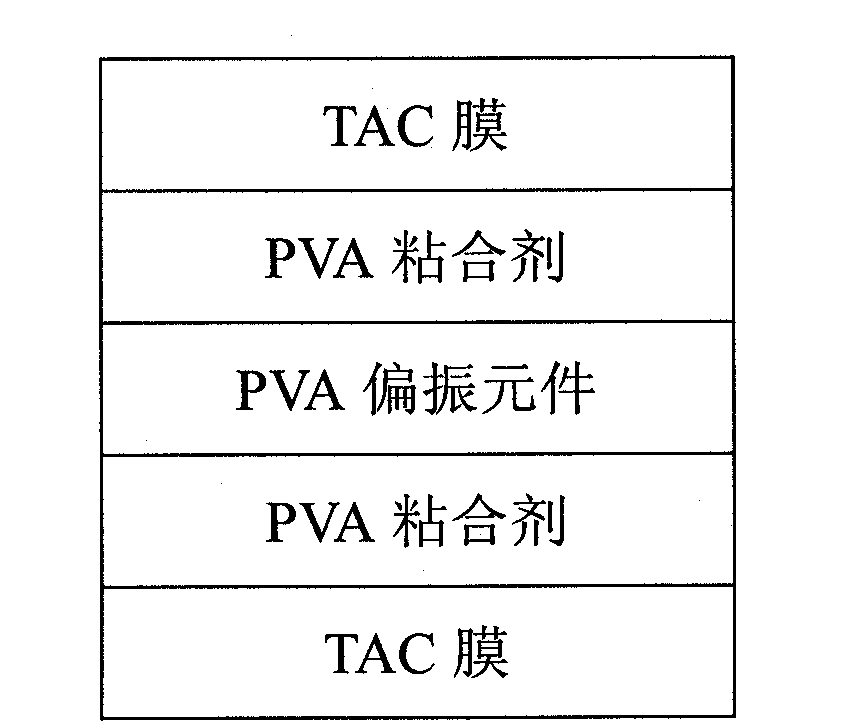

[0061] A 6 wt% aqueous solution was prepared by diluting Kymene-557H (compound containing an azetidinium group and an amine group) (Hercules Korea, 12.5 wt% aqueous solution) with pure water, and using this solution, the corona-treated Acrylic films were adhered to both sides of the polarizer. For the acrylate-based film, T-film produced by OPTES, Co., Ltd. and having a thickness of 80 μm was used. Make the surface of the membrane at 50W / m 2 / min under the condition of corona treatment. The adhesive was injected between the polarizing plate and the acrylate-based films on both sides thereof, rolled with a pressure roller, and dried using hot air at a temperature of 80° C. for 5 minutes, thereby preparing a polarizing plate.

Embodiment 2

[0063] After adding NaOH aqueous solution to make the pH of Kymene-557H (Hercules Korea, 12.5 wt% aqueous solution, pH = 5) to be 7, using a 6 wt% adhesive composition prepared by diluting it with pure water, the corona Treated acrylate-based films were adhered to both sides of the polarizer.

Embodiment 3

[0065] Using the adhesive composition of Example 2, a corona-treated acrylate-based film was adhered to one side of a polarizer and an alkali-treated TAC film was adhered to the other side of the polarizer superior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com