Oxygen-permeable membrane surface coated with modified material and method for preparing composite oxygen-permeable membrane

A technology of composite oxygen-permeable membrane sheet and modified material, which is applied in the field of mixed conductor oxygen-permeable membrane material and its preparation, oxygen-permeable membrane material and its preparation field, and can solve the problem that the oxygen permeability and stability of the mixed-conductor oxygen-permeable membrane are not ideal. and other problems, to achieve the effect of improving oxygen permeability, improving stability, and combining firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

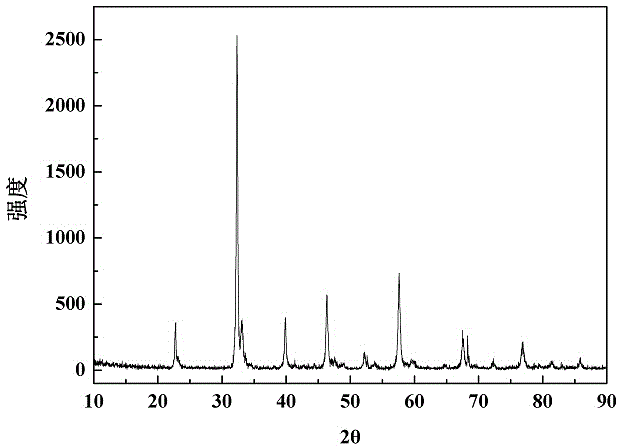

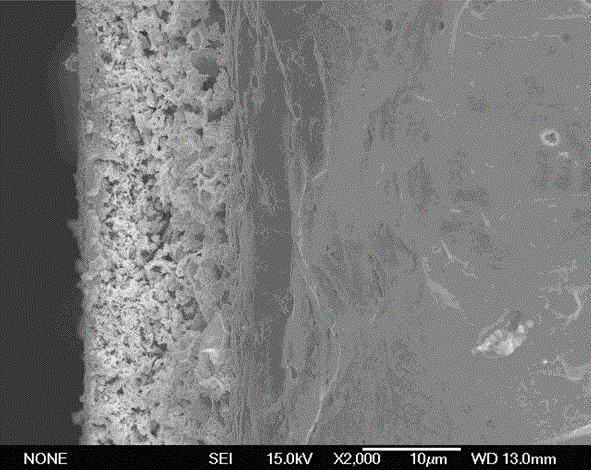

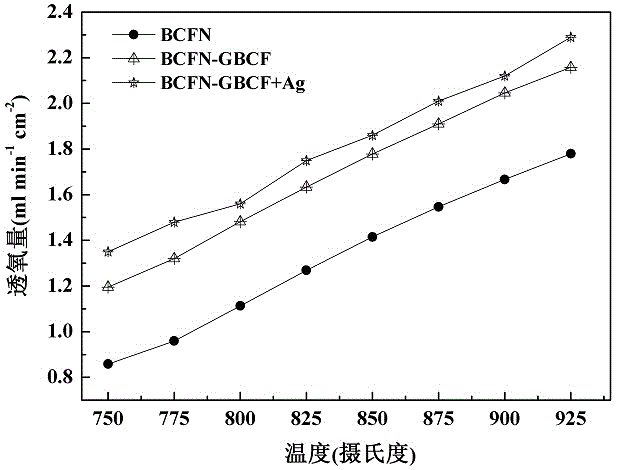

[0022] In this example, see figure 1 and figure 2 , the method for preparing a composite oxygen-permeable membrane by coating the modified material on the surface of the oxygen-permeable membrane has the following processes and steps:

[0023] 20.434 mmol of Ba(NO 3 ) 2 , 20.434 mmol of Co(NO 3 ) 2 ·6H 2 O, 20.434 mmol of Fe(NO 3 ) 3 9H 2 O and 10.217 mmol of Gd 2 o 3 Dissolve in 100 ml with a concentration of 0.5 mol·L -1 In the aqueous solution of nitric acid, stir until completely dissolved; according to the metal ion: ethylenediaminetetraacetic acid (EDTA): the mass ratio of citric acid is 1: 1: 2, accurately weigh the quality of EDTA and citric acid, add deionized water and Stir to dissolve the organic matter; mix the two obtained solutions, add ammonia water dropwise until the pH of the solution is 6.0, and keep the temperature of the solution at 90°C until the reactant becomes a sol. Dry the obtained sol-like substance at 110°C, take it out after the sol-l...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, especially in that:

[0028] In this embodiment, the method for preparing a composite oxygen-permeable membrane by coating the modified material on the surface of the oxygen-permeable membrane has the following processes and steps:

[0029] 20.434 mmol of Ba(NO 3 ) 2 , 40.868 mmol of Co(NO 3 ) 2 ·6H 2 O and 10.217 mmol of Gd 2 o 3 Dissolve in 100 ml with a concentration of 0.5 mol·L -1 In the aqueous solution of nitric acid, stir until completely dissolved; according to the metal ion: ethylenediaminetetraacetic acid (EDTA): the mass ratio of citric acid is 1:1:2, accurately weigh the quality of EDTA and citric acid, add deionized water and Stir to dissolve the organic matter; mix the two obtained solutions, add ammonia water dropwise until the pH of the solution is 6.5, and keep the temperature of the solution at 95°C until the reactant becomes a sol. Dry the obtained sol-like substance at 105°C, take it out...

Embodiment 3

[0032] This embodiment is basically the same as the previous embodiment, and the special features are:

[0033] In this embodiment, the method for preparing a composite oxygen-permeable membrane by coating the modified material on the surface of the oxygen-permeable membrane has the following processes and steps:

[0034] 20.434 mmol of La(NO 3 ) 3 ·6H 2 O, 20.434 mmol of Co(NO 3 ) 2 ·6H 2 O, 20.434 mmol of Fe(NO 3 ) 3 9H 2 O and 10.217 mmol of Gd 2 o 3 Dissolve in 100 ml of nitric acid aqueous solution with a concentration of 0.5 mol L, stir until completely dissolved; accurately weigh EDTA and To the quality of citric acid, add deionized water and stir to dissolve the organic matter; mix the two obtained solutions, add ammonia water dropwise until the pH of the solution is 6.0, and keep the temperature of the solution at 90°C until the reactant becomes a sol. Dry the obtained sol-like substance at 110°C, take it out after the sol-like substance expands into a spon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com