Application of a fluorine-doped perovskite membrane in oxygen separation

A perovskite-type, fluorine-doped technology, used in semi-permeable membrane separation, separation methods, dispersed particle separation, etc., can solve the problems of low flux, difficult to meet industrial applications, etc. The effect of low activation energy and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare material Ba of the present invention with solid state reaction method 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ f 0.1 As an example, the commercially available SrCO 3 , BaCO 3 ,Co 2 o 3 , Fe 2 o 3 , and SrF 2 After the powder is mixed, add ethanol, put it in a ball mill for 6 hours, rotate at a speed of 450rpm, and then dry it in static air. The dried powder is roasted in an air atmosphere at 900°C for 8 hours, and after grinding, a particle with a particle size of about 1 μm is obtained. Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ f 0.1 Powder.

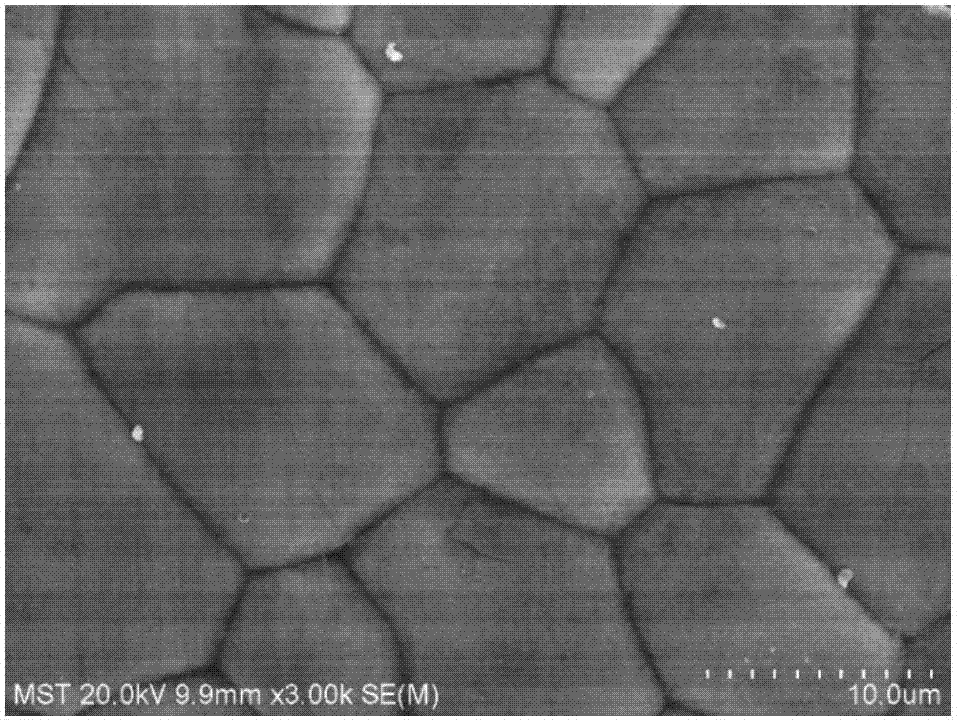

[0028] The powder was prepared under a uniaxial pressure of 200MPa to prepare a green film, and the heating rate was controlled to be 2°C / min. After the green film was sintered at 1050°C for 8 hours, the temperature was lowered to room temperature at a rate of 2°C / min. Type membrane (membrane thickness is 1mm). The surface micrograph of the membrane is shown in figure 1 . It can be seen from the figure that the membran...

Embodiment 2

[0033] Prepare material Pr of the present invention with solid state reaction method 0.2 Sr 0.8 Fe 0.9 Nb 0.1 o 3-δ f 0.4 As an example, the commercially available SrCO 3 , Pr 2 o 3 , Nb 2 o 5 , Fe 2 o3 , and FeF 3 After the powder is mixed, add ethanol, put it in a ball mill for 3 hours, rotate at a speed of 400rpm, and then dry it in static air. The dried powder is roasted in an air atmosphere at 1200°C for 10 hours, and after grinding, a powder with a particle size of about 5 μm is obtained. PR 0.2 Sr 0.8 Fe 0.9 Nb 0.1 o 3-δ f 0.4 Powder.

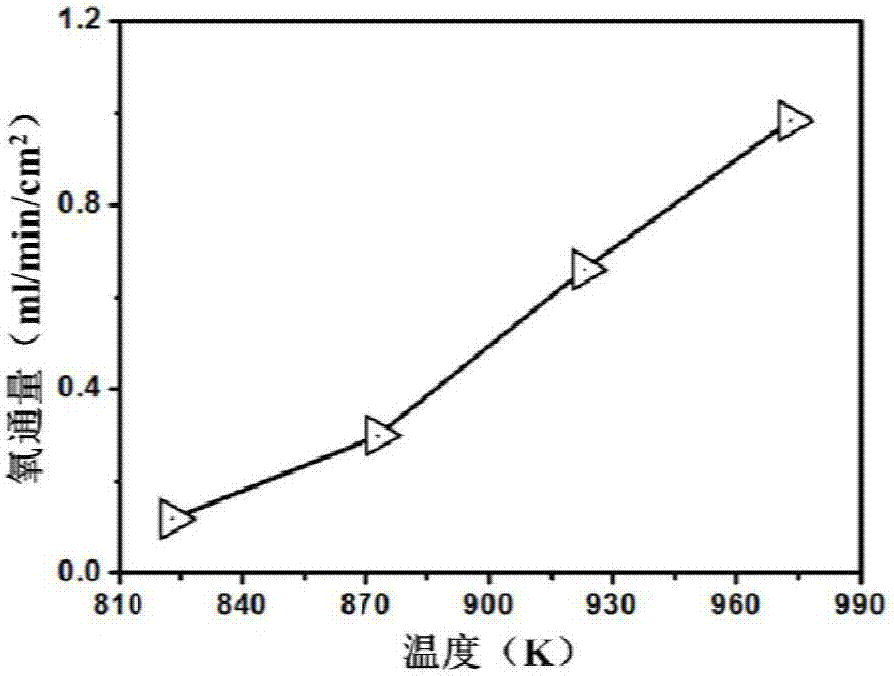

[0034] The hollow fiber membrane green body is prepared by the powder through the phase inversion method, and the heating rate is controlled at 4°C / min. After the membrane green body is sintered at 1300°C for 15 hours, the temperature is lowered to room temperature at a rate of 4°C / min, and the hollow fiber membrane is obtained. fibrous membranes, such as Figure 4 As shown, the thickness of the dense layer of the memb...

Embodiment 3

[0038] Prepare material La of the present invention with solid state reaction method 0.9 Ca 0.1 co 0.4 Mo .6 o 3-δ f 0.7 As an example, the commercially available CaCO 3 , La 2 o 3 ,Co 2 o 3 , MoO 3 , and CoF 3 After the powder is mixed, add ethanol, put it in a ball mill for 8 hours, rotate at a speed of 550rpm, and then dry it in static air. The dried powder is roasted in an air atmosphere at 1000°C for 5 hours, and after grinding, a particle with a particle size of about 200nm is obtained. La 0.9 Ca 0.1 co 0.4 Mo .6 o 3-δ f 0.7 Powder.

[0039] The powder is made of a tubular film green body by plastic extrusion, and the heating rate is controlled at 5°C / min. After the film green body is sintered at 1200°C for 20 hours, the temperature is lowered to room temperature at a rate of 5°C / min, and the tube is obtained. Type membrane

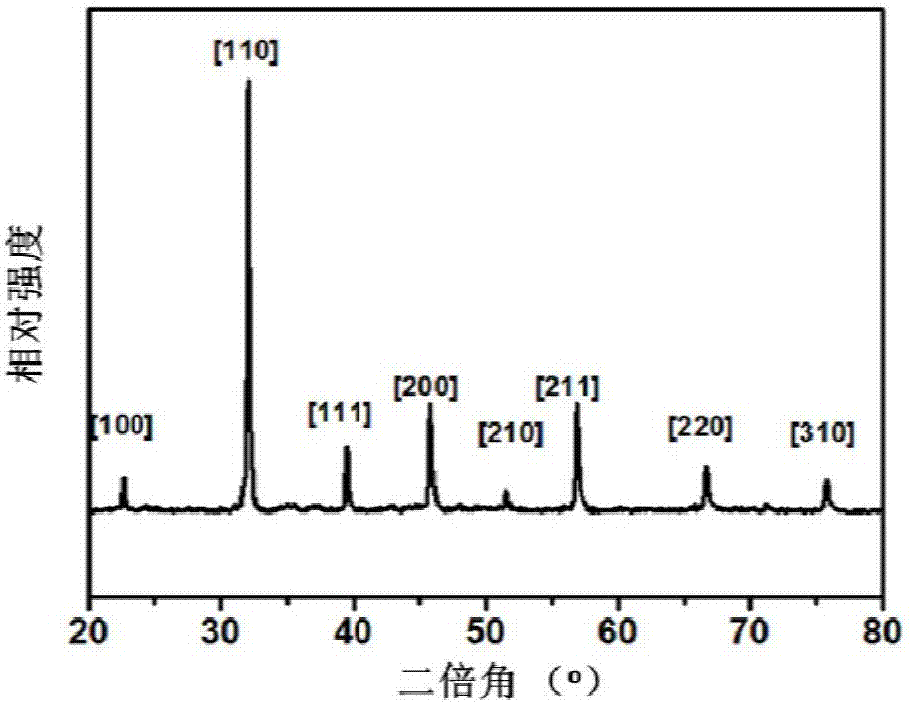

[0040] La 0.9 Ca 0.1 co 0.4 Mo .6 o 3-δ f 0.7 The X-ray diffraction test of the powder shows that it has a complete perovs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com