A kind of preparation method of sulfonated microporous polymer with high temperature resistance and high gas permeability for fuel cell and platinum-carbon composite membrane

A microporous polymer and fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of easy scale-up production, high conductivity, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

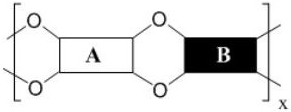

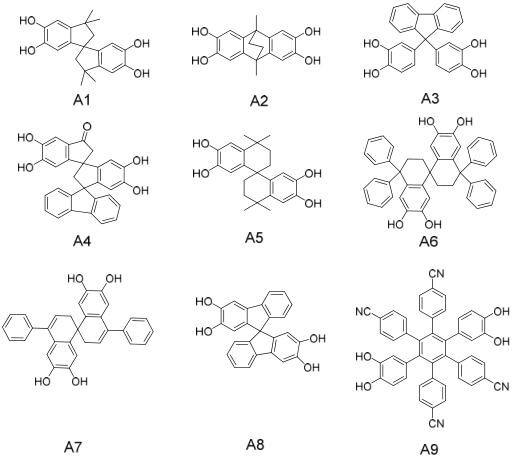

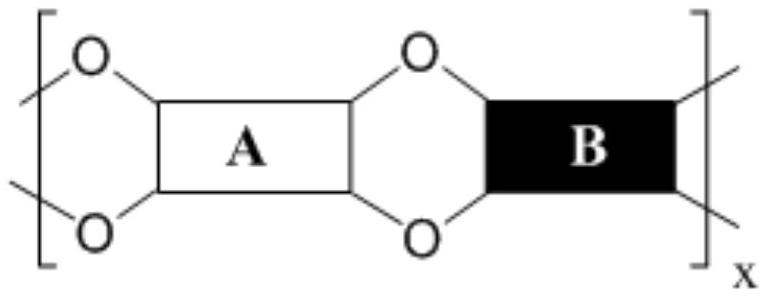

[0031] (1) Preparation of sulfonated self-porous polymers. A four-neck flask equipped with a stirrer, a thermometer and an adapter was placed in a constant temperature oil bath. In a nitrogen atmosphere, the anhydrous K 2 CO 3 (120mmol, 16.5852g), tetrahydroxy monomer A1 (60mmol, 20.4252g), tetrafluoromonomer B1 (60mmol, 18.6114g) and anhydrous DMF (390mL) were added in a four-necked flask, first stirred at room temperature for 1 hours, and then reacted at 80°C for 2 hours. After the reaction, cool to room temperature, add distilled water, filter to obtain a filter cake, wash the filter cake with methanol and distilled water successively, and vacuum-dry to constant weight to obtain sulfonated microporous polymer powder.

[0032] (2) Preparation of sulfonated self-porous polymer mixture. The dried polymer powder was dissolved in NMP to form a polymer solution with a solid content of 8 wt.%. Then use a 0.45 μm filter membrane to filter, that is, the sulfonated self-micropor...

Embodiment 2

[0035] (1) Preparation of sulfonated self-porous polymers. A four-necked flask equipped with a stirrer, a thermometer and an adapter was placed in a constant temperature oil bath. In a nitrogen atmosphere, the anhydrous K 2CO 3 (120mmol, 16.5852g), tetrahydroxy monomer A2 (60mmol, 17.9004g) and tetrafluoromonomer B2 (60mmol, 21.615g) and anhydrous DMF (405mL) were added in the four-necked flask, first stirred at room temperature for 2 hours, and then reacted at 100°C for 5 hours. After the reaction, cool to room temperature, add distilled water, filter to obtain a filter cake, wash the filter cake with methanol and distilled water successively, and vacuum-dry to constant weight to obtain sulfonated microporous polymer powder.

[0036] (2) Preparation of sulfonated self-porous polymer mixture. The dried polymer powder was dissolved in DMF to form a polymer solution with a solid content of 9 wt.%. Then use a 0.45 μm filter membrane to filter, that is, the sulfonated self-mi...

Embodiment 3

[0039] (1) Preparation of sulfonated self-porous polymers. A four-necked flask equipped with a stirrer, a thermometer and an adapter was placed in a constant temperature oil bath. In a nitrogen atmosphere, the anhydrous K 2 CO 3 (120mmol, 16.5852g), tetrahydroxy monomer A3 (60mmol, 22.9452g), tetrafluoromonomer B3 (60mmol, 21.615g) and anhydrous DMF (446mL) were added in the four-necked flask, first stirred at room temperature for 1 hours, and then reacted at 150°C for 12 hours. After the reaction, cool to room temperature, add distilled water, filter to obtain a filter cake, wash the filter cake with methanol and distilled water successively, and vacuum-dry to constant weight to obtain sulfonated microporous polymer powder.

[0040] (2) Preparation of sulfonated self-porous polymer mixture. The dried polymer powder was dissolved in tetrahydrofuran to prepare a polymer solution with a solid content of 6 wt.%. Then use a 0.45 μm filter membrane to filter, that is, the sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com