Extrusion machining method of copper-chromium alloy

A copper-chromium alloy, extrusion processing technology, applied in electrical components, electrical switches, circuits and other directions, can solve the problems of high manufacturing cost, low yield, easy cracking, etc., to reduce production costs, improve yield, extrusion low pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

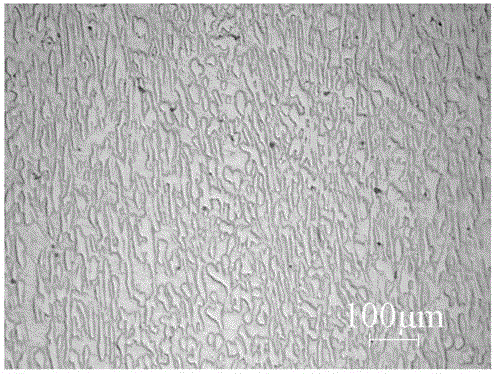

Embodiment 1

[0033] 1) Prepared by melting and casting method 76mm×160mm CuCr (25) alloy ingot;

[0034] 2) Polish the surface of the spindle to remove the slag on the surface to obtain 69mm×130mm CuCr (25) alloy ingot;

[0035] 3) Use a copper plate with a thickness of 0.40mm and a hardness of HB75 to tightly cover the cylindrical surface of the spindle and one end surface, and use argon arc welding to weld the copper plate at the junction;

[0036] 4) Apply a layer of lubricant with a thickness of about 0.4mm evenly on the outside of the copper plate. The lubricant is composed of No. 45 engine oil, graphite powder, and zinc stearate, and its mass percentage is: 70:24:6;

[0037] 5) Put the ingot on the 800T extrusion machine according to the direction of the copper plate-coated end facing the extrusion die. The extrusion die adopts a cone die, and the inner diameter of the extrusion cylinder is 71mm, sizing hole of extrusion die 32mm, that is, the extrusion ratio is 5, the cone a...

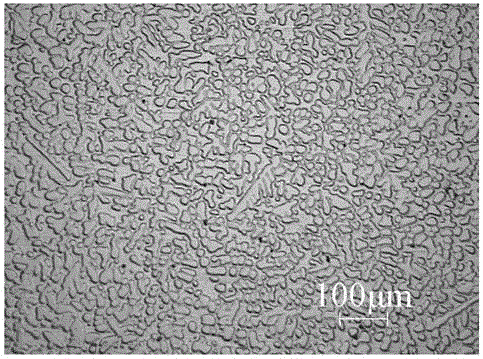

Embodiment 2

[0039] 1) Prepared by arc melting method 76mm×160mm CuCr (40) alloy ingot;

[0040] 2) Polish the surface of the spindle to remove the slag on the surface to obtain 69mm×130mm CuCr (40) alloy ingot;

[0041] 3) Use a copper skin with a thickness of 0.50mm and a hardness of HB130 to tightly cover the cylindrical surface of the spindle and one end surface, and use argon arc welding to weld the copper skin at the junction;

[0042] 4) Apply a layer of lubricant with a thickness of about 0.3mm evenly on the outside of the copper skin. The lubricant is composed of No. 45 engine oil, molybdenum disulfide powder, and zinc stearate, and its mass percentage is: 60:36:4;

[0043] 5) Put the ingot on the 800T extruder according to the direction of the copper skin-coated end facing the extrusion die. The extrusion die adopts a cone die, and the inner diameter of the extrusion cylinder is 71mm, sizing hole of extrusion die 35mm, that is, the extrusion ratio is 4, the cone angle 2α ...

Embodiment 3

[0045] 1) Prepared by infiltration method 72mm×140mm CuCr (50) alloy ingot;

[0046] 2) Polish the surface of the spindle to remove the slag on the surface to obtain 64mm×110mm CuCr (50) alloy ingot;

[0047] 3) Use a copper tube with a thickness of 0.75mm and a hardness of HB100 to tightly cover the cylindrical surface of the spindle and one end surface, and use argon arc welding to weld the copper tube at the junction;

[0048]4) Apply a layer of lubricant with a thickness of about 0.2mm evenly on the outside of the copper tube. The lubricant is composed of No. 45 engine oil, graphite powder, and zinc stearate, and its mass percentage is: 65:30:5;

[0049] 5) Put the ingot on the 800T extruder according to the direction of the copper pipe-coated end facing the extrusion die. The extrusion die adopts a cone die, and the inner diameter of the extrusion cylinder is Extrusion die sizing hole That is, the extrusion ratio is 3.5, the cone angle 2α is 65°, the length of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com