A high-temperature heat treatment-resistant data Matrix code label and its manufacturing method

A production method and high-temperature-resistant technology, applied in marking, ion implantation plating, coating, etc., can solve problems such as gasification, non-reusable, and polluted DM codes, and achieve improved recognizability, wide application range, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

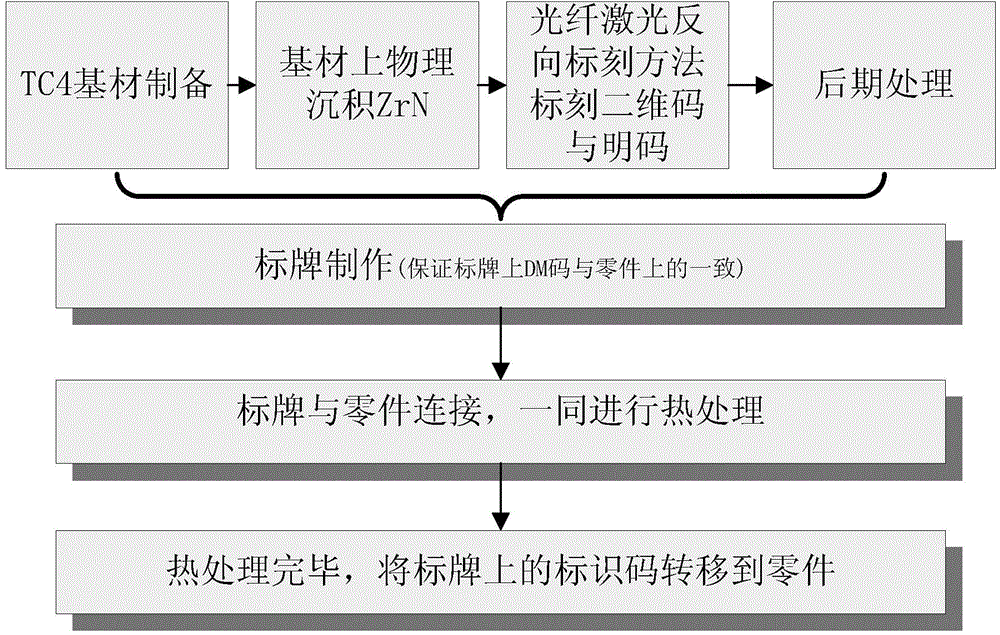

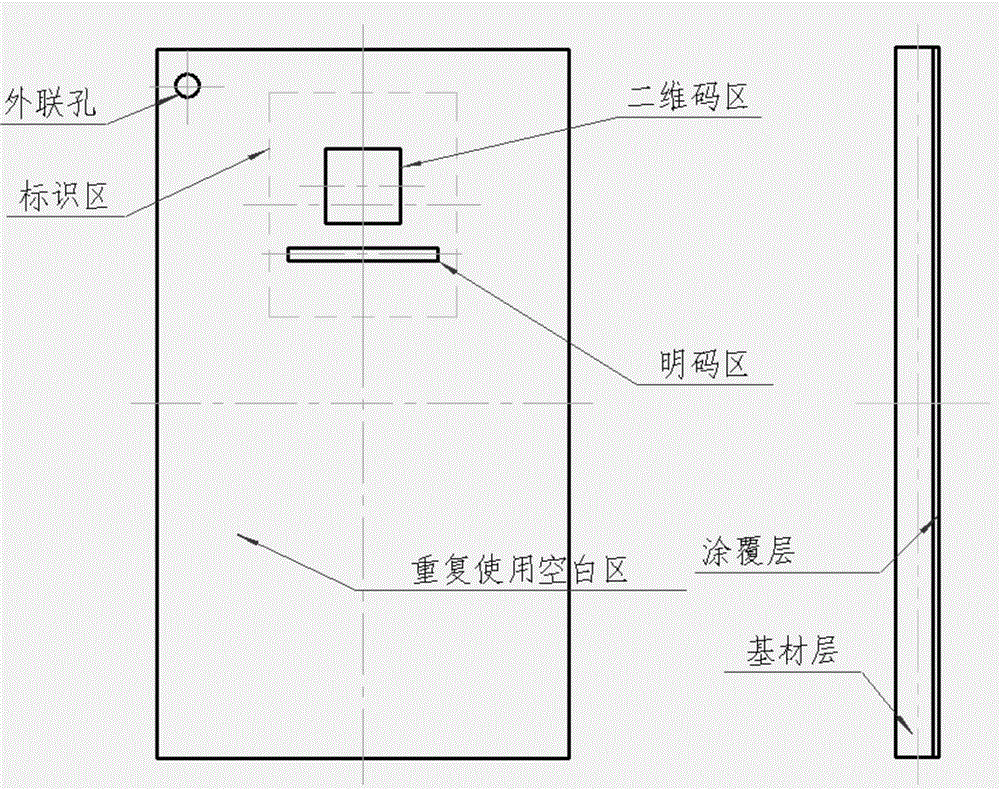

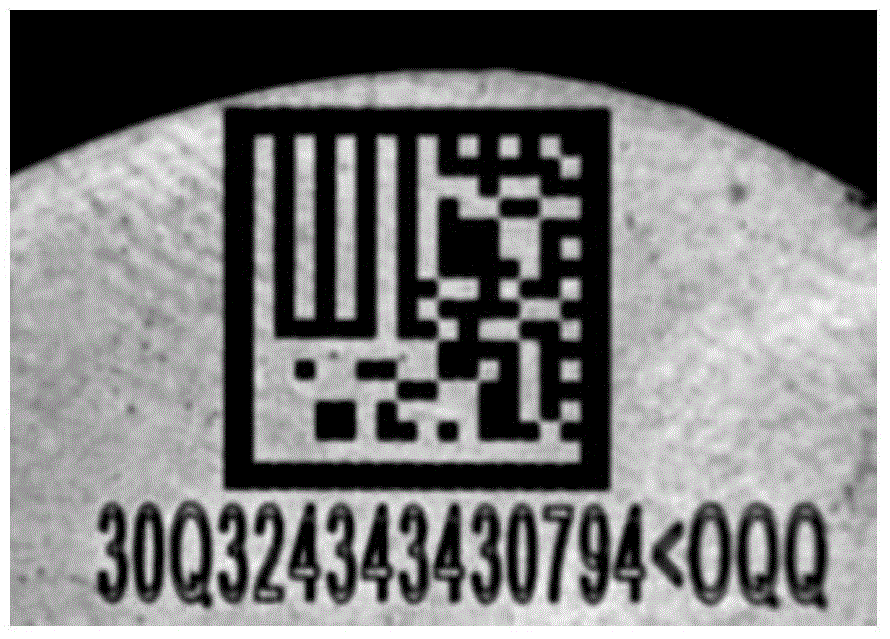

Method used

Image

Examples

Embodiment 1

[0058] In this embodiment, a titanium alloy plate with a brand name of TC4 is used as the substrate, and ZrN is used as the coating.

[0059] Step 1: Substrate preparation:

[0060] Step 1.1: Prepare a titanium alloy sheet with the grade TC4, and turn the sheet into a rectangular TC4 titanium alloy sheet with a length of 80 mm, a width of 60 mm, and a thickness of 1 mm through machining.

[0061] Step 1.2: Polish the two-dimensional code marking surface of the TC4 titanium alloy rectangular thin plate step by step with emery paper to ensure its surface roughness Ra=0.8.

[0062] Step 2: substrate cleaning, mainly including the following sub-steps:

[0063] Step 2.1: Degreasing: Degreasing the TC4 titanium alloy rectangular thin plate prepared in step 1, the degreasing time is 20 minutes, the working temperature is room temperature, and the degreasing solvent is trichloroethylene.

[0064] Step 2.2: Etching and descaling: Descaling the TC4 titanium alloy rectangular sheet by ...

Embodiment 2

[0083] In this embodiment, a titanium alloy plate with a brand name of TC4 is used as the substrate, and ZrN is used as the coating.

[0084] Step 1: Substrate preparation:

[0085] Step 1.1: Prepare a titanium alloy sheet with the brand name TC4, and turn the sheet into a rectangular TC4 titanium alloy sheet with a length of 80 mm, a width of 60 mm, and a thickness of 2 mm through machining.

[0086] Step 1.2: Polish the two-dimensional code marking surface of the TC4 titanium alloy rectangular thin plate step by step with emery paper to ensure that its surface roughness is Ra=0.6.

[0087] Step 2: substrate cleaning, mainly including the following sub-steps:

[0088] Step 2.1: Degreasing. Degreasing the TC4 titanium alloy rectangular thin plate prepared in step 1, the degreasing time is 20 minutes, the working temperature is room temperature, and the degreasing solvent is trichlorethylene.

[0089] Step 2.2: Etching and descaling. The descaling treatment of TC4 titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com