A kind of processing method of aluminum alloy medium and thick plate

A processing method and aluminum alloy technology, which is applied in the field of aluminum alloy medium and thick plates, can solve the problems that the surface deformation of the rolled plate is larger than that of the center, the structure of the plate is uneven in the height direction, and the size of the tool and mold is unstable. The effect of reduction, uniform structure and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

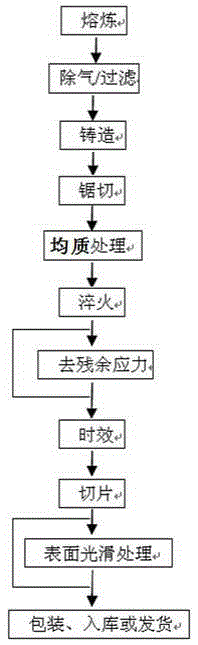

Method used

Image

Examples

Embodiment 1

[0038] According to SI0.2kg; mg0.5kg; CU1.0kg; CR0.22kg; Fe0.1kg; Zn0.3kg; Ti0.02kg; V0.2kg; ZR0.02kg and Al97.44kg, add a melting agent with a weight content of 2%contentThen heated the material to 600 to 1000 ° C to keep the material from melting 1 to 10h, filter out the non -melting material in the aluminum melt, cool to room temperature, get aluminum alloy ingot blank, cut the aluminum alloy ingot into 6mm thickness, thicknessThe board; keep the board at 48 ° C for 4h, and then immediately use a spray -type quenching to control the plate. The cooling speed of the plate is about 10 ° C / second.The timing of the board is carried out by 20h, cut into a certain thickness through the timeliness processing, and then use the milling method and grinding method to smoothly treat it to obtain the thick plate in the aluminum alloy and the packaging into the warehouse.

[0039] During the melting, the pupae are refined and the electromagnetic stirring is applied.

Embodiment 2

[0041] According to SI0.6kg; mg0.9kg; CU0.8kg; CR0.09kg; mn0.1kg; Zn0.05kg; Ti0.05kg; V0.02kg; ZR0.08kg and Al97.31kg mix, add melter with a weight of 3%contentThen heated the material to 600 to 1000 ° C to keep the material from melting the state of 1 to 10h, filter out the non -melting material in the aluminum melt, cool to room temperature, get aluminum alloy ingot blank, cut the aluminum alloy ingot into 20mm thickness, thicknessThe board; keep the board at 520 ° C for 3h, and then immediately use a spray -type quenching to control the plate. The cooling speed of the plate is about 8 ° C / second.Perform the timing of 15h, cut the plates that have been processed into a certain thickness, and then use the milling method and grinding method to smoothly treat it to obtain the thick plate in the aluminum alloy and pack it into the warehouse.

[0042] During the melting, the pupae are refined and the electromagnetic stirring is applied.

Embodiment 3

[0044] According to SI0.8kg; mg1.2kg; CU0.6kg; CR0.02kg; mn1.0kg; Fe0.3kg; Ti0.12kg; V0.3kg and Al95.66kg mix, add 4%melting agent with weight content, and then heating materialsTo 600 ~ 1000 ° C, keep the material of 1 to 10h, filter out the non -melting material in the aluminum melt, cool to room temperature, get aluminum alloy ingots, cut the aluminum alloy ingot into a 50mm thick plate;The plate is insulated for 2h at 550 ° C, and then the plate is immediately quenched with spray -type quenching to control the cooling speed of the board is about 6 ° C / second.The timeliness processing, cut into a certain thickness after the timeliness processing, then use the milling method and grinding method to smooth the surface, obtain the thick board in the aluminum alloy, and the packaging into the warehouse.

[0045] During the melting, the pupae are refined and the electromagnetic stirring is applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com