Elevated short process energy-saving rkef nickel-iron alloy production equipment and technology

A technology of nickel-iron alloy and production equipment, applied in the field of metallurgy, can solve the problems of unfavorable electric furnace high temperature flue gas recycling, large difference in RKEF process, easy blocking of pipelines for flue gas transportation, etc., achieving significant energy saving effect, reducing environmental protection investment, and solving smoke The effect of dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

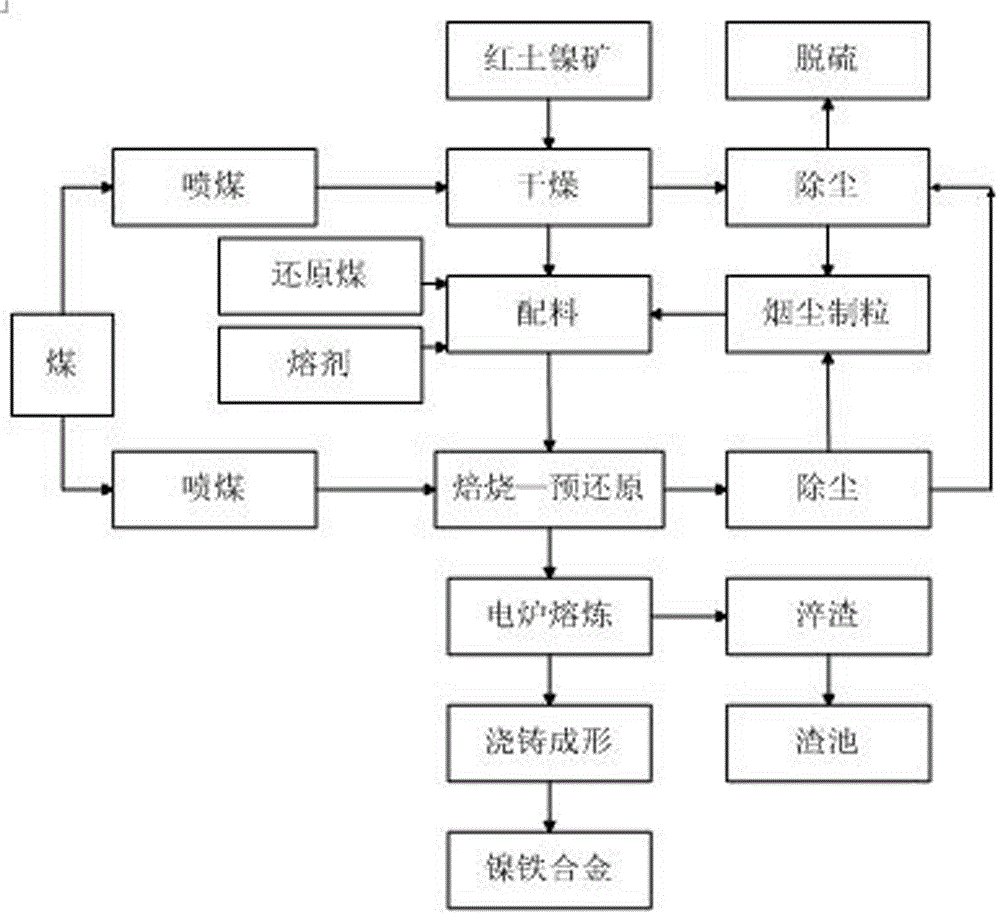

[0035] Such as figure 1 As shown, the laterite nickel ore is dried through a rotary kiln. The ore contains 30% water before drying, and is dried to about 20% water. The drying kiln uses the high-temperature flue gas of the electric furnace as fuel, and reserves coal injection equipment as spare and supplementary equipment. After drying, the laterite nickel ore, reduced coal, flux and soot particles are evenly mixed and then enter the rotary kiln for roasting—pre-reduction. When the roasting temperature is 700°C~800°C, the crystallization water will be released during roasting, and only 0.5% of the crystallization water will be left. ~0.7%, by spraying coal powder into the rotary kiln, the coal powder will generate a reducing atmosphere, reduce some iron, nickel and cobalt oxides in the laterite nickel ore, and control the reduction temperature at about 1000 ° C to prevent the rotary kiln from forming rings. The reduced calcined sand is heated to 900°C, moves toward the tail o...

Embodiment 2

[0037] Such as figure 1 As shown, in this embodiment, on the basis of Example 1, in order to avoid the waste slag generated after smelting from polluting the environment, the waste slag generated during the electric furnace smelting process is treated with slag quenching, and the waste slag is discharged into the slag yard for unified treatment. At the same time, smoke and dust will be generated during the drying of laterite nickel ore and the roasting-pre-reduction process, so dust removal equipment is installed. The dust removal equipment is preferably an electric precipitator. At the same time, in order to avoid air pollution, the dust removal flue gas needs to be desulfurized before being discharged. The dust removal efficiency of the electrostatic precipitator is 99.9%, which meets the emission standards required by environmental protection. After desulfurization treatment, it will not cause acid rain and other hidden dangers. Other parts of this embodiment are the same a...

Embodiment 3

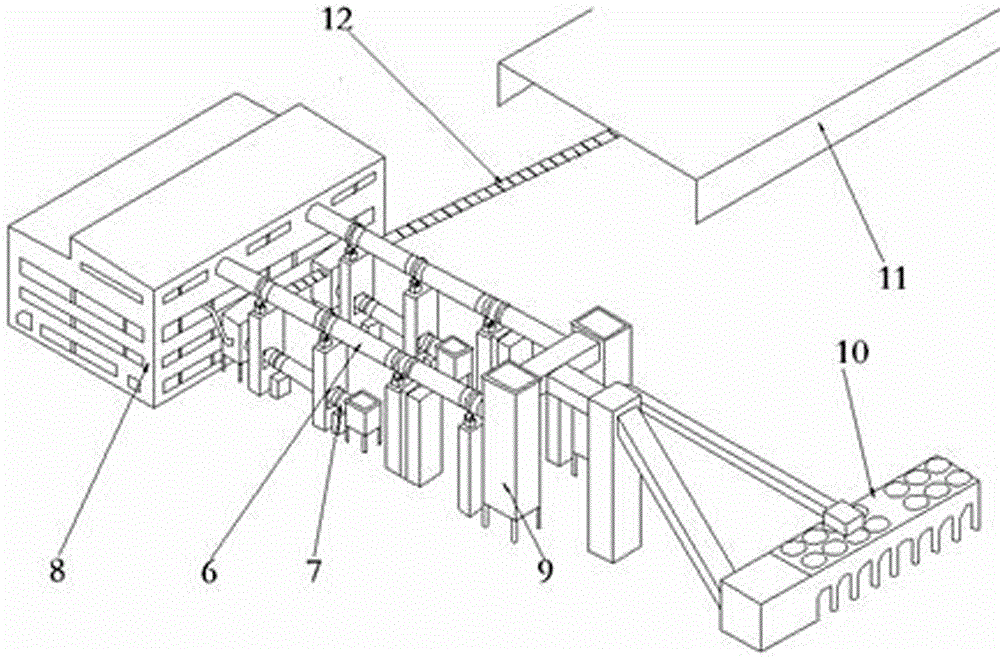

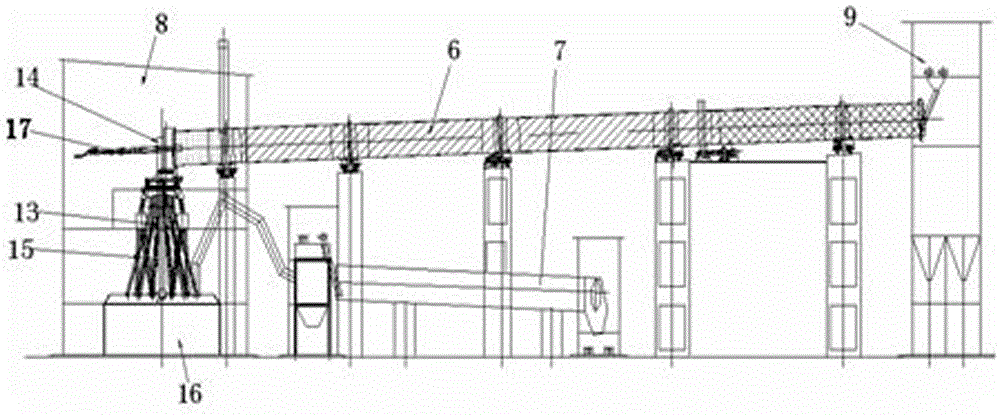

[0039] Such as figure 2 , image 3 As shown, the laterite ore is transported from the raw material warehouse 11 to the drying kiln 7 through the belt conveyor 12 for drying pretreatment, and the laterite nickel ore with a water content of ~20% from the drying kiln 7 enters the batching station 10 for batching, and then enters the rotary kiln 6, and the laterite ore After being roasted, dehydrated and reduced in the rotary kiln 6, it is transported to the electric furnace workshop 8 for high-temperature calcination and casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com