Tertiary air duct coal powder preheating and prefiring technique for cement predecomposition kiln

A technology of precalcining kiln and secondary air, which is applied in the field of pulverized coal preheating and precombustion in the tertiary air duct of cement precalcining kiln, which can solve the problems of fuel quality limitations, pipeline and preheater skin blockage, indirect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

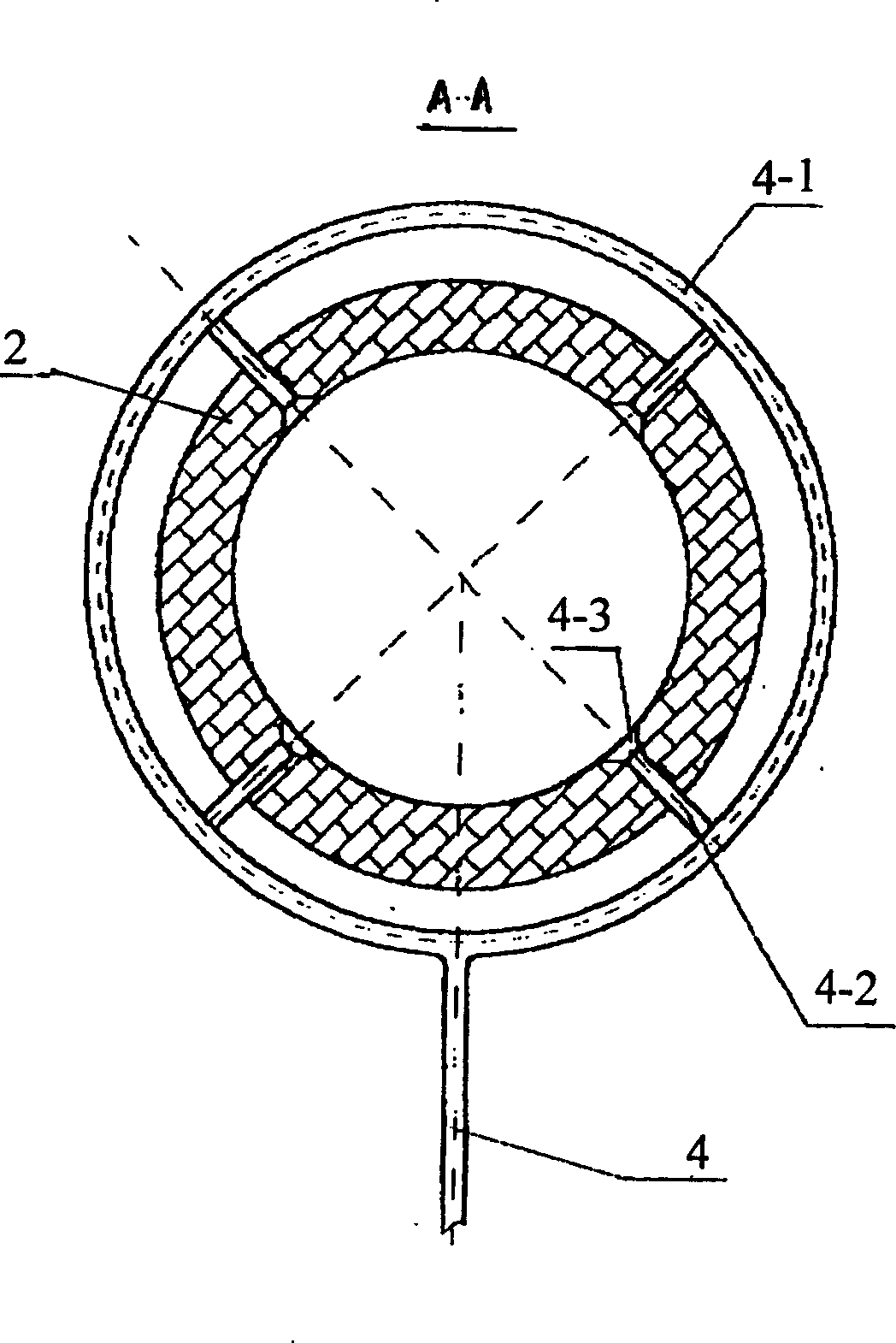

[0016] Such as figure 1 As shown: 3 in the figure is a rotary kiln, and a calciner 1 is set between it and the suspension preheaters C1, C2, C3, and C4 as the second heat source of the system. On the wall of the air duct 2, that is, place A is sprayed into the pulverized coal into the tertiary air duct, so that the pulverized coal and the tertiary hot air enter the calciner together. The pulverized coal is preheated and even pre-combusted during this process, so that when it reaches the calciner, the temperature of the tertiary air reaches 950°C-1000°C. This indicator can be easily achieved by adjusting the distance from A to the tertiary air inlet of the calciner and the ratio range of the pulverized coal entering the tertiary air pipe to the pulverized coal directly entering the calciner. Generally, A is 5-10m away from the tertiary air inlet of the calciner.

[0017] In order to prevent the impact of the injected coal powder on the wall of the tertiary air duct and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com