Non-polluting waste cracking gasifier with high-temperature superconducting tube

A high-temperature superconducting, pyrolysis gasification technology, applied in the high-temperature superconducting non-polluting waste pyrolysis gasifier, low energy consumption, high efficiency field, can solve the problem of large volume of waste treatment system, large waste of heat energy, and unavoidable smoke and tar and other issues, to achieve the effect of reducing the generation of dioxin precursors, curbing the generation and emission, and achieving obvious energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

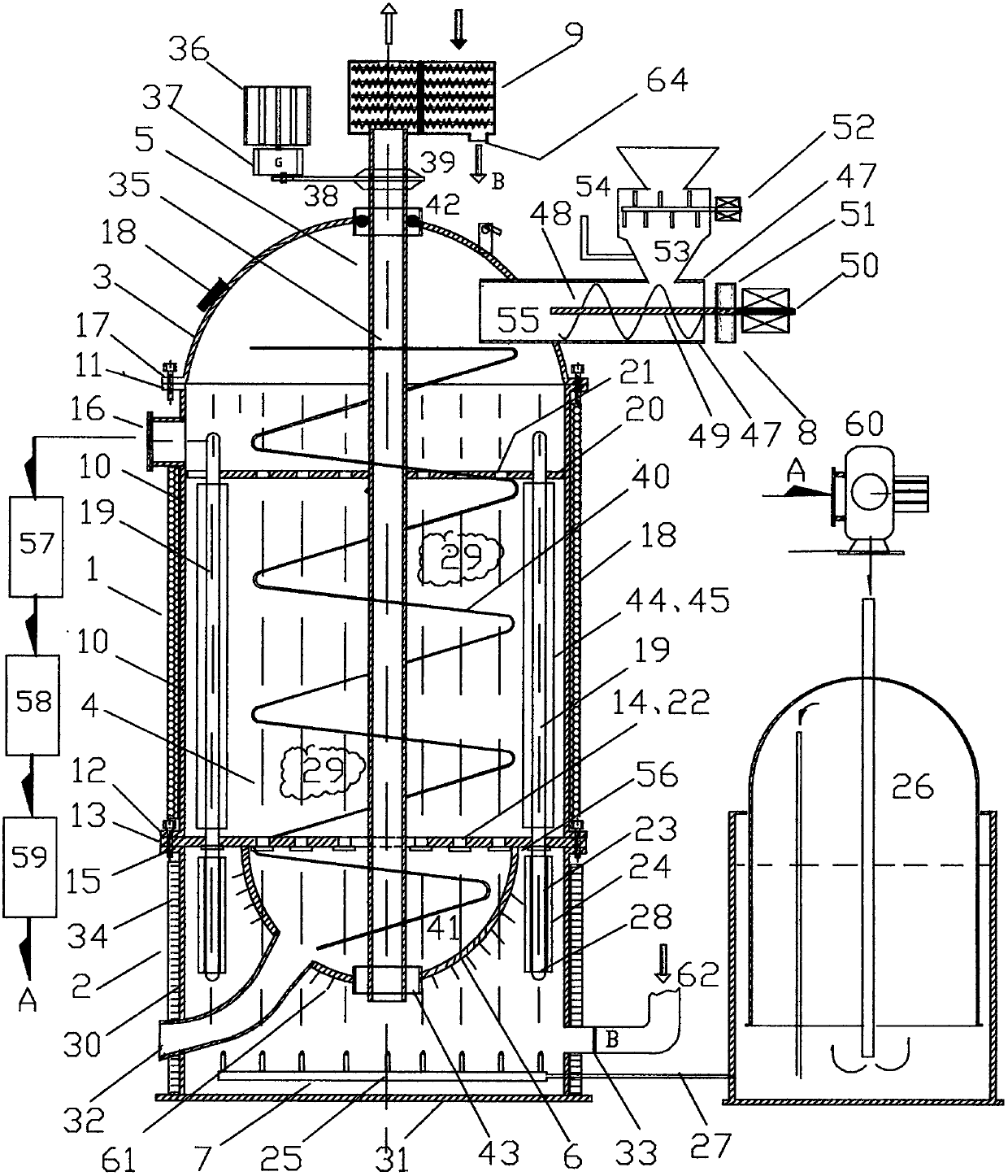

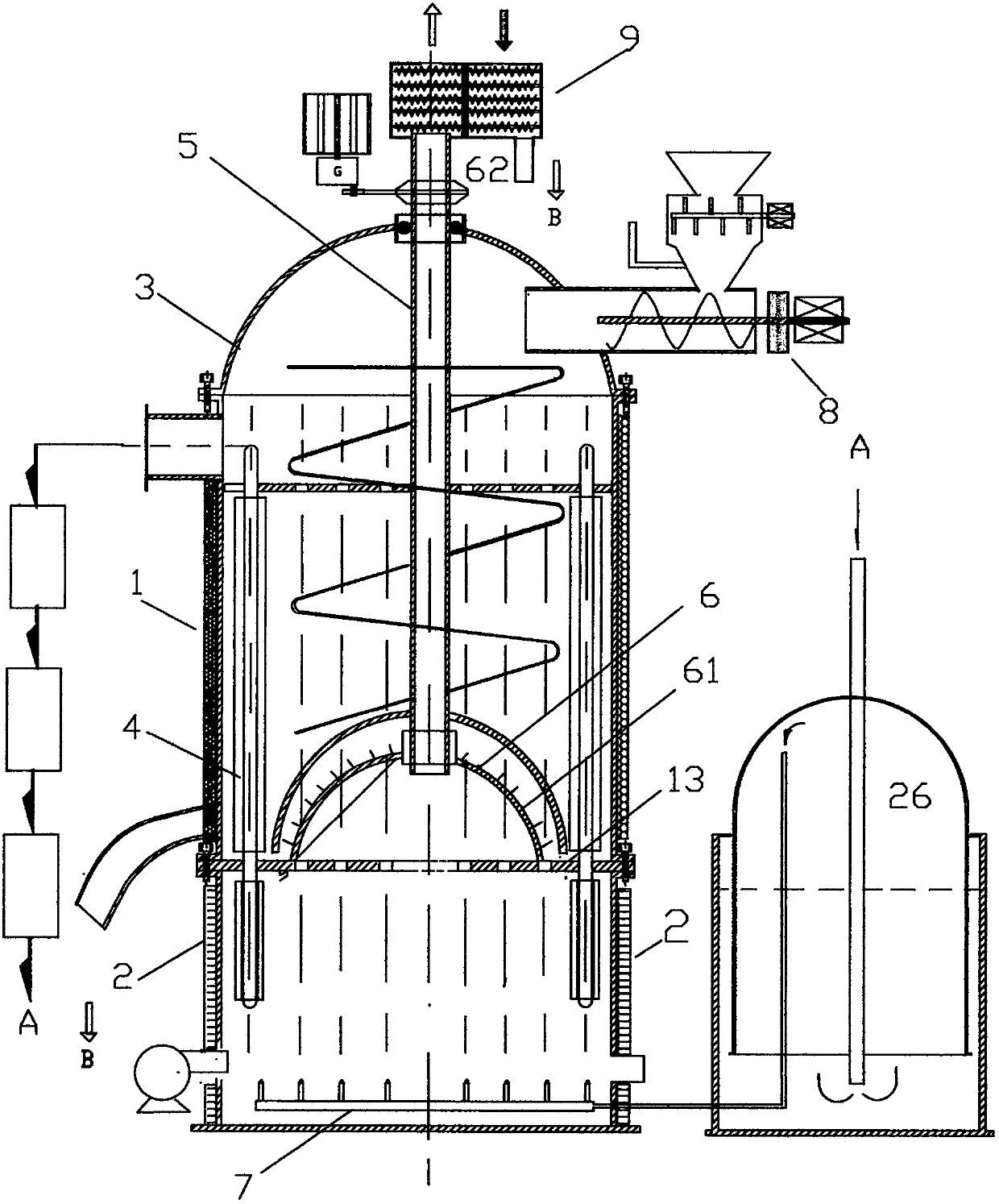

[0026] now attached figure 1 , attached figure 2 And attached image 3 To be specific:

[0027] A high-temperature superconducting pipe pollution-free garbage pyrolysis gasification furnace consists of a furnace body 1, a furnace base 2, a furnace cover 3, a high-temperature superconducting heat exchanger 4, a rotating smoke pipe radiator 5, a round head heat exchanger 6, and heating Device 7, feeder 8, superconducting waste heat recovery device 9. It is characterized in that the furnace body 1 is composed of a cylindrical shell 10, an upper flange 11 connected to the upper and lower edges of the cylindrical shell 10, a lower flange 12, and a circle connected to the lower flange 12 below the lower flange 12. The hole flange 13, the round head heat exchanger 6 connected to the inner circle of the round hole flange 13, the cylindrical shell 9, the round hole flange 13 and the round head heat exchanger 6 form a round platform 56, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com