Hydrocarbon substance aging resisting instrument cable for petrochemical plant and manufacturing method thereof

A technology for instrument cables and petrochemical equipment, which is applied in the manufacture of hydrocarbon aging resistant instrument cables and hydrocarbon aging resistant instrument cables for petrochemical equipment. It can solve the problems of wasting time, limited use occasions, and not easy to bend. It achieves the effect of simple terminal processing, ensuring the safety of use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

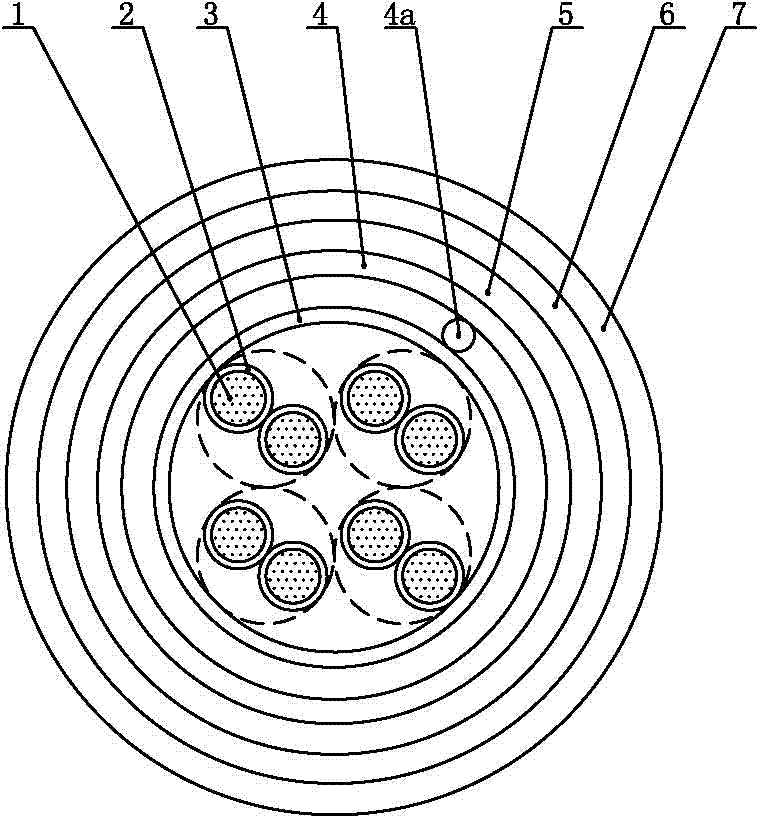

[0018] like figure 1As shown, the hydrocarbon aging-resistant instrument cable for petrochemical equipment of the present invention comprises the following steps in turn: uniformly extrude an insulating layer 2 on the outer periphery of the stranded copper conductor 1 to form an instrument cable insulated core, and the instrument cable insulated core is divided into two pairs. Twisted to form a pair of twisted wires, multiple pairs of twisted wires are twisted to form an instrument cable core, and the outer periphery of the instrument cable core is wrapped with a flame-retardant and fire-resistant longitudinal tape 3, and the outer periphery of the flame-retardant and fire-resistant longitudinal tape 3 is wrapped Aluminum foil composite shielding strip 4, the aluminum foil of the aluminum foil composite shielding strip 4 faces inward and the inner side is provided with a copper wire drainage line 4a, the copper wire drainage line 4a runs through the entire length of the aluminu...

Embodiment 2

[0023] like figure 1 As shown, the hydrocarbon aging-resistant instrument cable for petrochemical equipment of the present invention comprises the following steps in turn: uniformly extrude an insulating layer 2 on the outer periphery of the stranded copper conductor 1 to form an instrument cable insulated core, and the instrument cable insulated core is divided into two pairs. Twisted to form a pair of twisted wires, multiple pairs of twisted wires are twisted to form an instrument cable core, and the outer periphery of the instrument cable core is wrapped with a flame-retardant and fire-resistant longitudinal tape 3, and the outer periphery of the flame-retardant and fire-resistant longitudinal tape 3 is wrapped Aluminum foil composite shielding strip 4, the aluminum foil of the aluminum foil composite shielding strip 4 faces inward and the inner side is provided with a copper wire drainage line 4a, the copper wire drainage line 4a runs through the entire length of the alumin...

Embodiment 3

[0028] like figure 1 As shown, the hydrocarbon aging-resistant instrument cable for petrochemical equipment of the present invention comprises the following steps in turn: uniformly extrude an insulating layer 2 on the outer periphery of the stranded copper conductor 1 to form an instrument cable insulated core, and the instrument cable insulated core is divided into two pairs. Twisted to form a pair of twisted wires, multiple pairs of twisted wires are twisted to form an instrument cable core, and the outer periphery of the instrument cable core is wrapped with a flame-retardant and fire-resistant longitudinal tape 3, and the outer periphery of the flame-retardant and fire-resistant longitudinal tape 3 is wrapped Aluminum foil composite shielding strip 4, the aluminum foil of the aluminum foil composite shielding strip 4 faces inward and the inner side is provided with a copper wire drainage line 4a, the copper wire drainage line 4a runs through the entire length of the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com