A kind of production technology of hybrid polyester resin

A polyester resin and production process technology, applied in the production process field of mixed polyester resin, can solve the problems of few production methods, no production process, centralized production, etc., and achieves fast curing speed, improved acid and alkali resistance, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

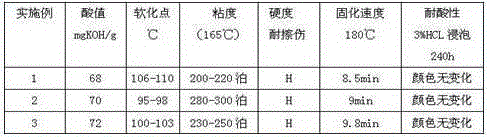

Examples

Embodiment 1

[0021] Example 1: The concrete preparation method of the production of a kind of hybrid polyester resin of the present invention is as follows: Slurry configuration: the trimethylolpropane of 40mol, the propylene glycol of 30mol, the trimethylol propane of 10mol, the ethylene glycol acetate of 20mol and 100mol of p-hydroxybenzoic acid is put into the powder silo to configure mixed slurry, mixed and stirred for 1h; the molar mass ratio of trimethylolpropane to p-hydroxybenzoic acid during the slurry configuration process is 1:10;

[0022] Esterification: Add the prepared mixed slurry into the reaction kettle. The reaction kettle uses heat-conducting oil as the carrier. Under the temperature condition of 180°C, gradually increase the temperature and keep it warm for 1 hour every time the temperature rises by 10°C. When the temperature reaches 245°C , heat preservation reaction 2h;

[0023] Polycondensation: After the esterification reaction is completed, continue to keep the te...

Embodiment 2

[0031] Example 2: The concrete preparation method of the production of a kind of hybrid polyester resin of the present invention is as follows: Slurry configuration: the trimethylolpropane of 40mol, the propylene glycol of 30mol, the trimethylolpropane of 12mol, the ethylene glycol acetate of 20mol and 98mol of p-hydroxybenzoic acid is put into the powder hopper to configure mixed slurry, mixed and stirred for 1h; the molar mass ratio of trimethylolpropane to p-hydroxybenzoic acid in the slurry configuration process is 1.2:10;

[0032] Esterification: Add the prepared mixed slurry into the reaction kettle. The reaction kettle uses heat-conducting oil as the carrier. Under the temperature condition of 180°C, gradually increase the temperature and keep it warm for 1 hour every time the temperature rises by 10°C. When the temperature reaches 245°C , heat preservation reaction 3h;

[0033] Polycondensation: After the esterification reaction is completed, continue to keep the tem...

Embodiment 3

[0041] Example 3:The concrete preparation method of the production of a kind of hybrid polyester resin described in the present invention is as follows: Slurry configuration: the trimethylol propane of 40mol, the propylene glycol of 30mol, the trimethylolpropane of 11.5mol, the ethylene glycol acetate of 20mol Put the p-hydroxybenzoic acid of 100mol into the powder hopper to configure the mixed slurry, mix and stir for 1h; the molar mass ratio of the molar mass of trihydroxymethylpropane to the total substance in the slurry configuration process is 1.15:10;

[0042] Esterification: Add the prepared mixed slurry into the reaction kettle. The reaction kettle uses heat-conducting oil as the carrier. Under the temperature condition of 180°C, gradually increase the temperature and keep it warm for 1 hour every time the temperature rises by 10°C. When the temperature reaches 245°C , insulation reaction 2.5h;

[0043] Polycondensation: After the esterification reaction is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com