Novel process for treating ABS wastewater

A new process, wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of chemical environmental pollution, long process flow, treatment requirements, etc. Achieve the effect of improving system stability and high efficiency, high processing efficiency, and low filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

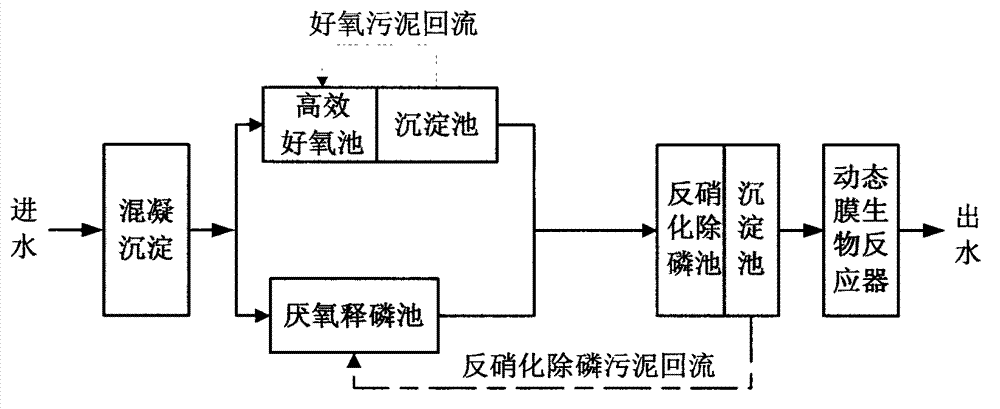

[0015] Implementation case 1: Wastewater treatment is from Tianjin Dagu Chemical Co., Ltd., which produces 400,000 tons of mixed wastewater discharged from ABS resin plant workshops annually. The water quality is COD: 2000-3000mg / L, SS: 600-800mg / L, ammonia nitrogen : 20~40mg / L, TP: 20~30mg / L. The integrated technology of the present invention "coagulation sedimentation + parallel series biological enhancement treatment system + dynamic membrane bioreactor" is used as the treatment process of this project.

[0016] (1) Coagulation and sedimentation process: the conventional chemical coagulant PAC is selected as the treatment agent, and the dosing pump is used to quantitatively add it to the wastewater for mechanical stirring, and then flows to the sedimentation tank for mud-water separation. This unit mainly removes most of the suspended solids and some organic matter, colloidal particles, phosphorus and other substances.

[0017] (2) Parallel-series biological enhanced treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com