Preparation method of zinc oxide nano film, sensor electrode and electrochemical sensor

A zinc oxide nano-electrochemical technology, applied in the field of nano-materials, can solve problems such as cumbersome methods and complicated preparation processes, and achieve the effects of good reproducibility, high product purity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of zinc oxide nano film, comprising the following steps:

[0026] a. Put the zinc flakes into ethanol and water in turn for ultrasonic cleaning for 15 minutes;

[0027] b. Mix 20mL of absolute ethanol and 0.1mL of 12mol / L concentrated hydrochloric acid and add it into a 60mL reaction kettle, immerse the treated zinc flakes in the mixture, tighten the lid of the kettle, react at 80°C for 2 hours, and take out the reaction kettle Naturally cool to room temperature, rinse with ethanol and double distilled water successively, and dry at room temperature to obtain a zinc oxide nano film.

[0028] An electrochemical sensor electrode prepared by using a zinc sheet containing a zinc oxide nano film, the mass area ratio of the zinc oxide film to the zinc electrode is 0.0165g / cm 2 .

[0029] An electrochemical sensor prepared using electrodes comprising zinc flakes of zinc oxide nanofilms.

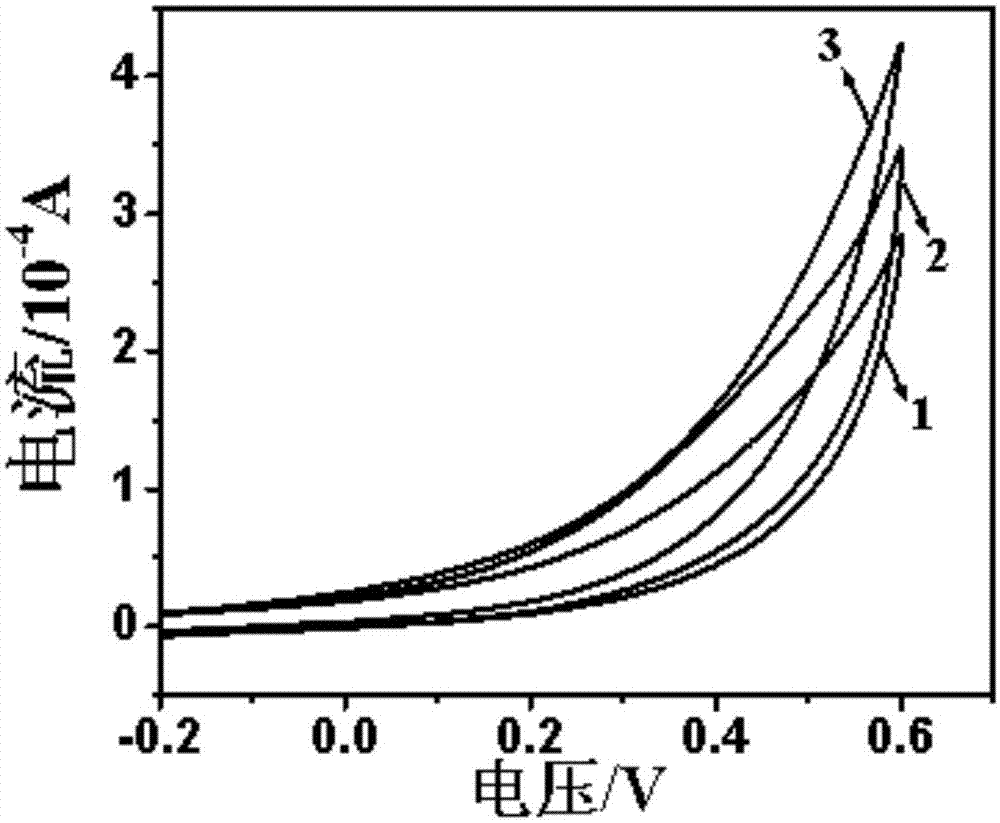

[0030] The zinc sheet coated with the zinc oxide nano-film prepar...

Embodiment 2

[0035] A preparation method of zinc oxide nano film, comprising the following steps:

[0036] a. Put the zinc flakes into ethanol and water in turn for ultrasonic cleaning for 20 minutes;

[0037] b. Mix 20mL of absolute ethanol and 0.4mL of 12mol / L concentrated hydrochloric acid and add it into a 60mL reaction kettle, immerse the treated zinc flakes in the mixture, tighten the lid of the kettle, react at 40°C for 4 hours, and take out the reaction kettle Naturally cool to room temperature, rinse with ethanol and double distilled water successively, and dry at room temperature to obtain a zinc oxide nano film.

[0038] An electrochemical sensor electrode is prepared using a zinc sheet containing a zinc oxide nano film.

[0039] An electrochemical sensor prepared using electrodes comprising zinc flakes of zinc oxide nanofilms.

Embodiment 3

[0041] A preparation method of zinc oxide nano film, comprising the following steps:

[0042] a. Put the zinc flakes into ethanol and water in turn for ultrasonic cleaning for 15 minutes;

[0043] b. Mix 20mL of absolute ethanol and 0.8mL of 12mol / L concentrated hydrochloric acid and add it into a 60mL reaction kettle, immerse the treated zinc flakes in the mixture, tighten the lid of the kettle, react at 40°C for 2 hours, and take out the reaction kettle Naturally cool to room temperature, rinse with ethanol and double distilled water successively, and dry at room temperature to obtain a zinc oxide nano film.

[0044] An electrochemical sensor electrode is prepared using a zinc sheet containing a zinc oxide nano film.

[0045] An electrochemical sensor prepared using electrodes comprising zinc flakes of zinc oxide nanofilms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com