Antistatic thermal-transfer-printing label cloth as well as preparation method thereof

A technology of thermal transfer printing and production method, which is applied in the processing of textile materials, weaving, fabrics, etc., can solve the problem of the antistatic property of the trademark belt and the overall preparation process to be improved, the lack of soft feel of the coated product, and the increase of the slitting product. Difficulty of finishing and other problems to achieve the effect of reducing crystal defects, stabilizing expansion and contraction changes, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

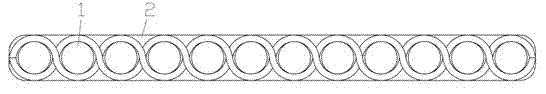

[0054] Such as figure 1 As shown, the antistatic and heat-transfer-printable trademark tape includes a base fabric layer 1 and an antistatic layer 2, and the thickness of the trademark tape is 0.100mm, and the grammage is 90g / m 2 The base fabric is made of PET material, the yarn specification of the base fabric is 60D-150D, the warp yarn density is 85 yarns / cm, and the weft yarn density is 30 yarns / cm; agent, and the weight of the antistatic agent accounts for 0.5% of the weight of the base cloth.

[0055] The manufacturing method of the trademark tape includes:

[0056] Gray cloth weaving: after weaving, obtain the base cloth described in the production of the trademark tape;

[0057] Dyeing and finishing treatment: including pre-dyeing and finishing treatment, dyeing and post-dyeing and finishing treatment, the pre-dyeing and finishing treatment adopts alkali desizing method, and the post-dyeing and finishing treatment includes continuous segmental shaping pre-shrinking pr...

Embodiment 2

[0067] Such as figure 1 As shown, the antistatic and heat-transfer-printable trademark tape includes a base fabric layer 1 and an antistatic layer 2, and the thickness of the trademark tape is 0.165mm and the weight is 150g / m 2 The base fabric is made of PET material, the yarn specification of the base fabric is 150D, the warp yarn density is 160 yarns / cm, and the weft yarn density is 45 yarns / cm; the base fabric is adhered with an antistatic agent, The weight of the antistatic agent accounts for 1.5% of the weight of the base cloth.

[0068] The manufacturing method of the trademark tape includes:

[0069] Gray cloth weaving: after weaving, obtain the base cloth described in the production of the trademark tape;

[0070] Dyeing and finishing treatment: including pre-dyeing and finishing treatment, dyeing and post-dyeing and finishing treatment, the pre-dyeing and finishing treatment adopts alkali desizing method, and the post-dyeing and finishing treatment includes continuo...

Embodiment 3

[0079] Such as figure 1 As shown, the antistatic and heat-transfer-printable trademark tape includes a base fabric layer 1 and an antistatic layer 2, the thickness of the trademark tape is 0.125mm, and the grammage is 120g / m 2 The base fabric is made of PET material, the yarn specification of the base fabric is 100D, the warp yarn density is 130 yarns / cm, and the weft yarn density is 40 yarns / cm; the base fabric is adhered with an antistatic agent, The weight of the antistatic agent accounts for 1% of the weight of the base cloth.

[0080] The manufacturing method of the trademark tape includes: alkali treatment;

[0081] Gray cloth weaving: after weaving, obtain the base cloth described in the production of the trademark tape;

[0082] Dyeing and finishing treatment: including pre-dyeing and finishing treatment, dyeing and post-dyeing and finishing treatment, the pre-dyeing and finishing treatment adopts alkali desizing method, and the post-dyeing and finishing treatment in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com