Washing mechanical equipment used for fabric and washing method thereof

A technology for cleaning machinery and fabrics, which is applied in the fields of equipment configuration for processing textile materials, processing textile material carriers, spraying/spraying textile materials, etc. It can solve problems such as waste products, fabrics stained with other colors, environmental pollution, etc., to reduce water consumption, Environmental pollution is small, the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

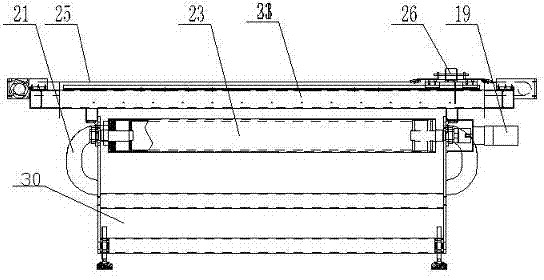

[0041] Examples such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a cleaning mechanical equipment for fabrics includes a frame 30 on which a fabric conveying and adsorption system and a cleaning device are installed.

[0042] The fabric conveying and adsorption system includes two transmission rollers 23 installed above the frame 30, and the two transmission rollers 23 are driven by a conveyor belt 22; one of the transmission rollers 23 is connected with a first servo motor 19;

[0043] The conveyor belt 22 is provided with sieve holes, and the rotary area of the conveyor belt 22 is provided with a suction box 20. The upper part of the suction box 20 is provided with a flat plate with sieve holes near the conveyor belt 22. The suction box 20 is connected with an exhaust fan through the air duct 21. .

[0044] The fabric 18 is dragged by the two conveyor belts 22 that are driven by the first servo motor 19, and the exhaust fan sucks the air in the suction box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com