Method for preparing ultra-fine grain titanium-based composite material by adopting equant bending channel deformation

A technology of equal-diameter bending of titanium-based composite materials, applied in the field of preparation of ultra-fine-grained titanium-based composite materials, to achieve the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

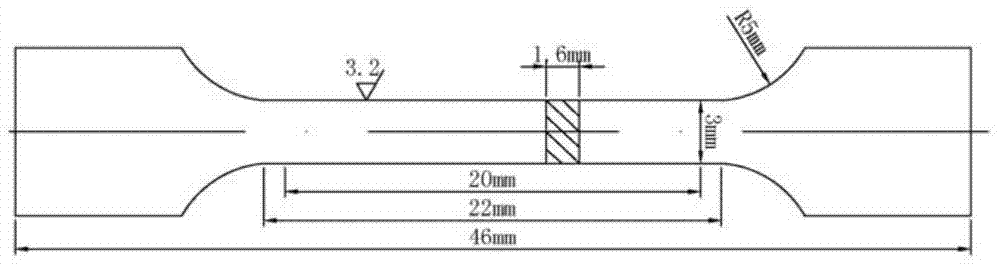

Image

Examples

Embodiment 1

[0026] The (TiB+TiC) / TC18 titanium-based composite material with a TiB:TiC molar ratio of 4:1 was cut into samples with a size of 10mm×10mm×100mm by a wire electric discharge machine, and the surface cut marks were ground off by a grinder. The deformation and extrusion test of the equal-diameter curved channel was carried out on a YA32-315 four-column universal hydraulic press. First adjust the press to lower it to a suitable height; put the mold into the heating furnace to preheat to 100°C (it can be any value from 100°C to 200°C, 100°C is selected in this embodiment), and keep it warm for 20 minutes (it can be Any value of 10 to 20 minutes, 20 minutes is selected in this embodiment) and then taken out, evenly smear molybdenum disulfide + graphite lubricant in the channel, the sample is also preheated to 100 ° C, after 20 minutes of heat preservation, the surface is evenly smeared with lubricant ; Assemble the mold, put the sample into the mold, and continue heating at 100°C ...

Embodiment 2

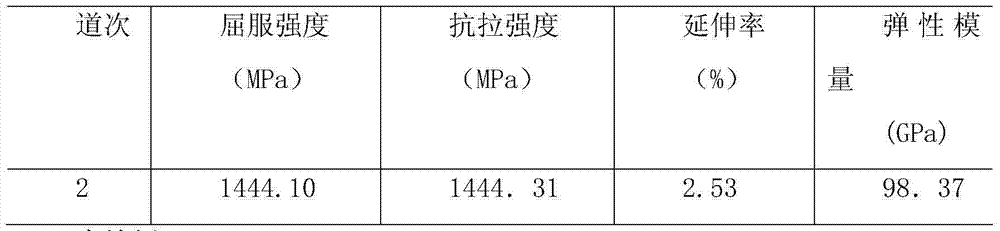

[0030] After straightening the bent sample, turn it 90° in the same direction to grind out the chamfer. Other conditions are the same as in Example 1. The sample is subjected to the second pass of extrusion deformation. The extrusion temperature is 600°C. The room temperature tensile property data measured after pressing is as shown in table 2:

[0031] Table 2 Mechanical properties of (TiB+TiC) / TC18 titanium-based composites extruded at 600°C in the second pass

[0032]

Embodiment 3

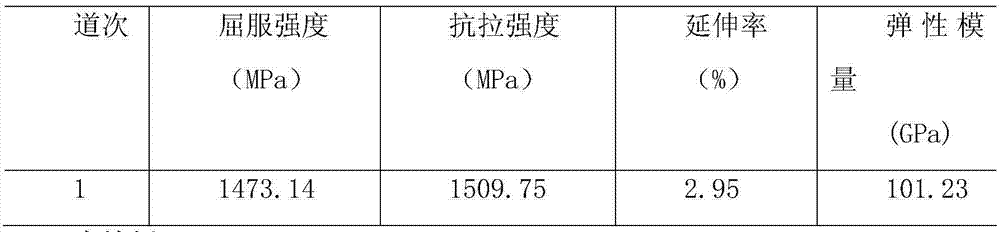

[0034] After straightening the bent sample, turn it 90° in the same direction to grind out the chamfer. Other conditions are the same as in Example 1. The sample is subjected to the third extrusion deformation at an extrusion temperature of 600°C. The room temperature tensile performance data measured after pressing is as shown in table 3:

[0035] Table 3 Mechanical properties of (TiB+TiC) / TC18 titanium-based composites extruded at 600℃ for three passes

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com