Vanadium oxide core-spun yarn for smelting vanadium microalloyed steel to increase vanadium content

A vanadium oxide and alloying technology, which is applied in the field of vanadium microalloyed steel vanadium-increasing additives outside the furnace, can solve the problems of increased labor intensity of workers, flying dust, high steelmaking costs, etc., and is conducive to safe production and vanadium volatilization Loss reduction and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

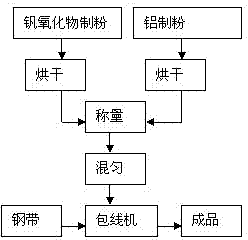

Method used

Image

Examples

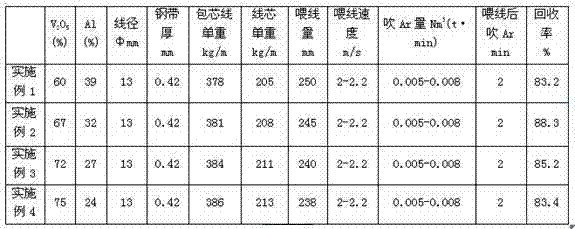

Embodiment 1

[0044] The diameter of the cored wire is Φ13mm, and the thickness of the outer sheath steel strip is 0.42mm. 2 o 5 Powder 60, metal Al powder 39, impurity surplus. The weight per unit length of the cored wire is 378g / m, and the weight per unit length of the core wire is 205g / m. It is used for 50t ladle to smelt 15MnV steel, the feeding amount per furnace is 250m, the feeding line speed is 2.0~2.2m / s, and the feeding line blowing Ar amount is 0.005~0.008Nm 3 (t·min) -1 , blowing Ar for two minutes after feeding the line, the recovery rate of vanadium was 83.2%. The data are listed in Table 1.

Embodiment 2

[0046] With embodiment 1, data is listed in table 1.

Embodiment 3

[0048] With embodiment 1, data is listed in table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com