Nature fiber reinforced thermoplastic resin unidirectional prepreg tape and preparation method thereof

A thermoplastic resin, unidirectional prepreg tape technology, applied in the field of composite material production and preparation, can solve the problems of screw wear, limited reinforcement effect, small fiber length and diameter of natural fiber reinforced materials, etc., to ensure performance stability, porosity, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

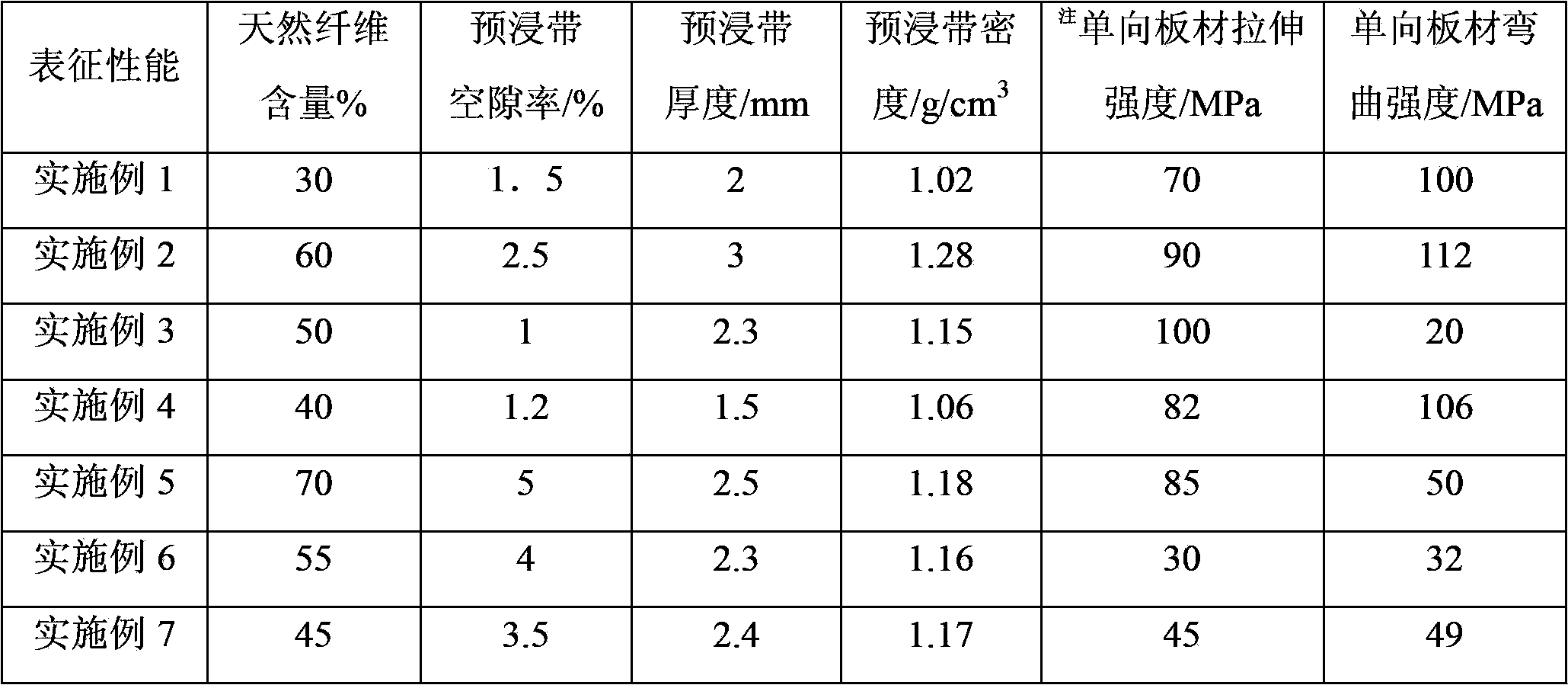

Embodiment 1

[0064] (1) Weigh 30 parts of jute fiber, 70 parts of polypropylene fiber (polypropylene fiber), 0.5 parts of emulsion (wherein the content of mineral oil is 20%, the content of milk soap is 0.9%, and the content of water is 79.1%), and Coupling agent vinyltrimethoxysilane 0.5 part; Utilize conveyor belt 1 to transport jute raw hemp (that is: natural fiber raw material) 2 into the opening machine 3 for opening ( figure 1 ), during the opening process, after adding emulsion and vinyltrimethoxysilane to open, store for 3 days;

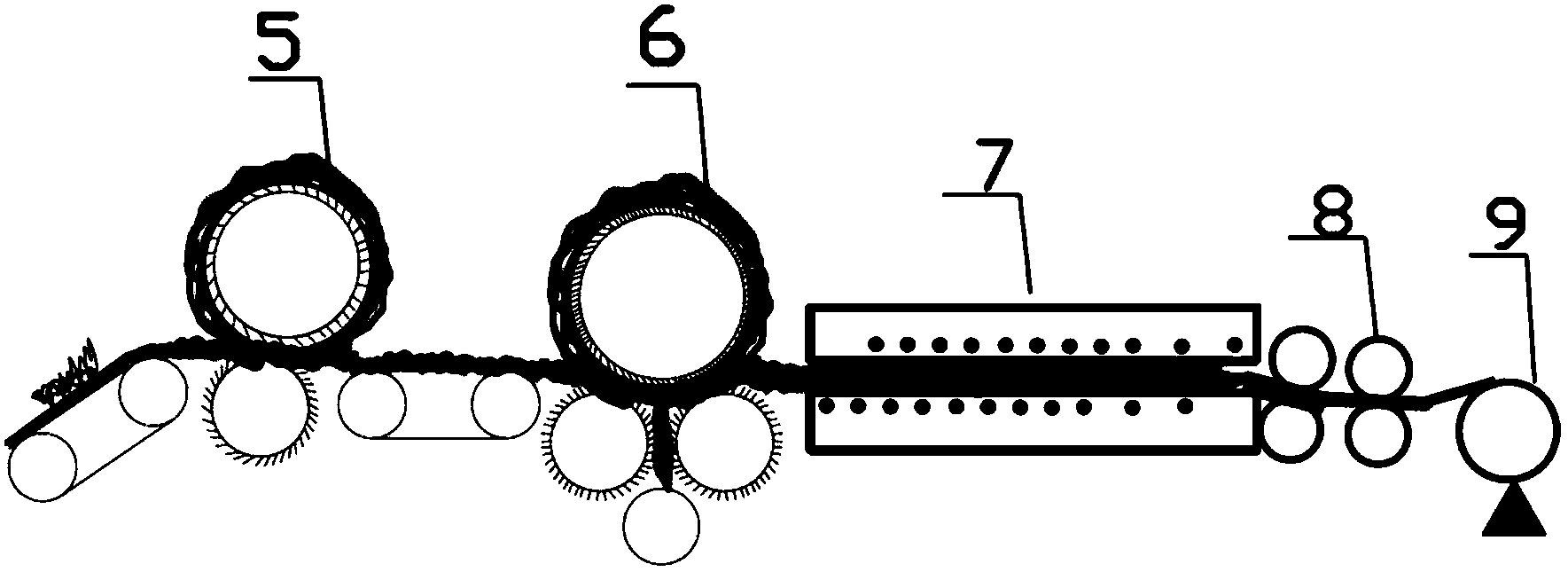

[0065] (2) Evenly spread the stocked jute and polypropylene segment fibers (that is, the natural fibers after opening) 4, and send them to the first carding machine 5 to form a roll; then put the roll into the second carding machine 6 In the second carding, a jute fiber / polypropylene fiber mixed roll with a width of about 20mm is formed ( figure 2 );

[0066] (3) Put the jute fiber / polypropylene fiber mixed roll into the heating oven 7 for heating, and...

Embodiment 2

[0069] (1) Weigh 60 parts of hemp fiber and 40 parts of polylactic acid fiber. The hemp fiber selected here is in the form of commercially available strips, which are directly mixed with polylactic acid;

[0070] (2) Spread the hemp fiber and the polylactic acid fiber evenly, and send them into the first carding machine 5 to form a roll; then put the roll into the second carding machine 6 for secondary carding to form a width of 30mm left and right hemp / polylactic acid mixed rolls;

[0071] (3) Put the hemp fiber / polylactic acid fiber mixed roll into the heating oven 7 for heating, and the heating temperature is 185°C;

[0072] (4) Then use the pressure roller 8 to roll the heated hemp fiber / polylactic acid fiber unidirectional prepreg tape, roll it once, the pressure is 8MPa, and then roll the rolled jute fiber / polypropylene fiber unidirectional The prepreg tape is wound up by a winder 9 . Obtain hemp fiber / polylactic acid fiber unidirectional prepreg tape. Its performance...

Embodiment 3

[0074] (1) Weigh 50 parts of ramie fiber and 50 parts of spandex fiber (polyurethane); the ramie fiber selected here is commercially available strips, which are directly mixed with spandex fiber;

[0075] (2) if figure 2 The ramie fiber and spandex fiber of alkali treatment are paved evenly as shown, and wherein ramie fiber is 50 parts, and spandex fiber is 50 parts, is sent in the head road carding machine 5, becomes roll; Then roll is put into secondary carding machine 6 During the second carding, because in the carding process, the fiber of ramie is relatively fine, and the dispersion is uneven, so the ramie fiber / spandex fiber roll needs to be carded three times;

[0076] (3) Put the ramie fiber / spandex fiber mixed roll into the heating oven 7 for heating, and the heating temperature is 210°C;

[0077] (4) Then use the pressure roller 8 to roll the heated ramie fiber / spandex fiber unidirectional prepreg tape, roll it twice, and the pressure is 2MPa, and then roll the rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com