Far infrared heat-radiation ceramic slurry, fiber cloth, thin film and preparation methods thereof

A far-infrared, ceramic slurry technology, applied in the field of fiber cloth and ceramic slurry, can solve the problem of low heat dissipation efficiency, achieve the effect of easy processing, improve product value and competitiveness, and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

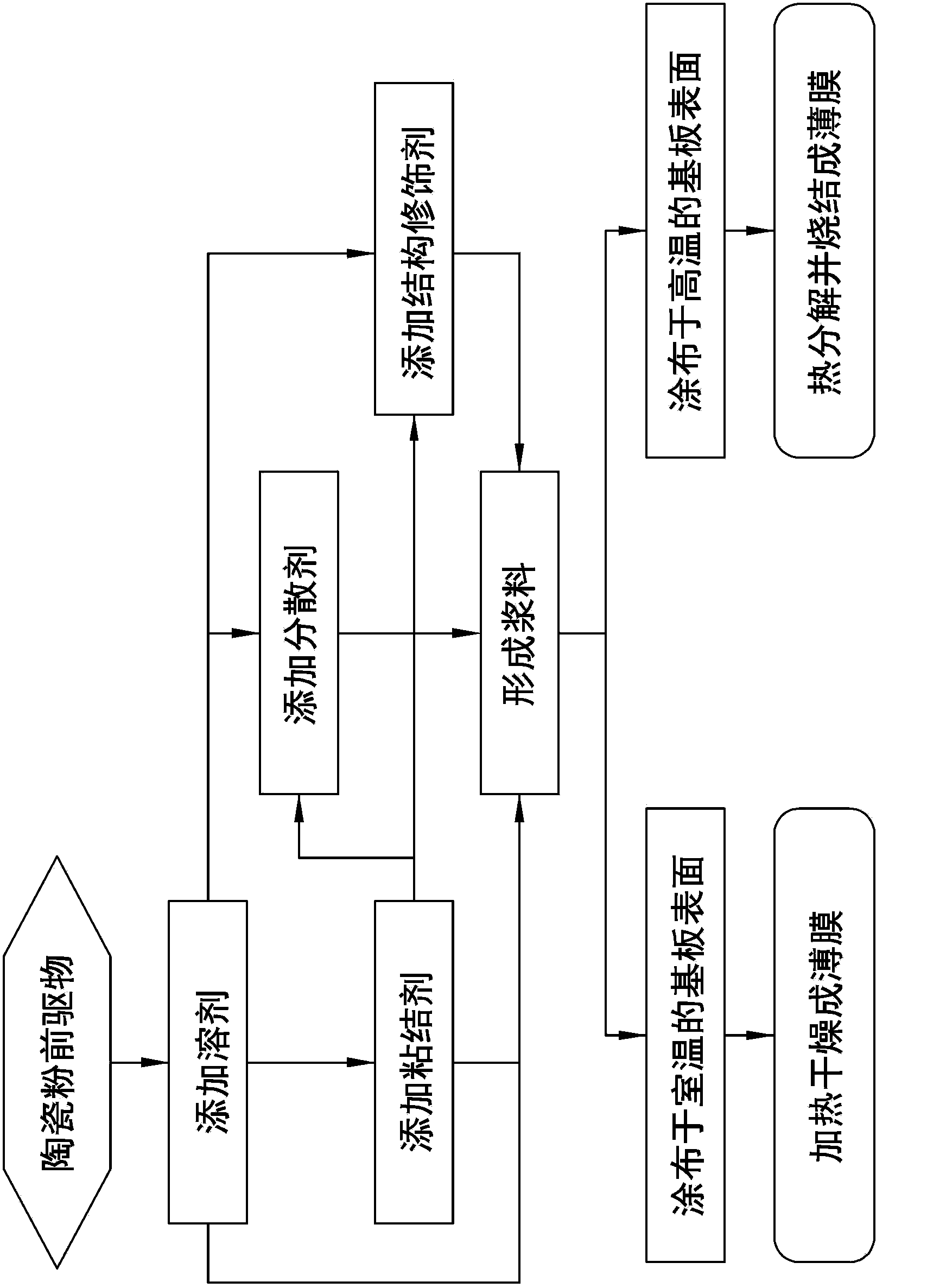

Method used

Image

Examples

Embodiment 1

[0053] Aluminosilicate Mullite 3Al 2 o 3 2SiO2 2 (20~40%) and NiCO 3 (≦10%) and Fe 2 o 3 (≦10%) After uniform mixing, add graphite (20~40%), MgCl at 200~800℃ 2 ·6H 2 O (30~50%), CaCl 2 ·6H 2 O(20~40%) and Na 2 SiO 3 9H 2 O (10~20%) for homogenization heat treatment for 1 hour, and then sintered at a high temperature of 1200~1400°C to form a ceramic powder precursor. The constant temperature time is about 6 hours. The ceramic powder precursor, deionized water, methyl cellulose and n-hexane were mixed and stirred at the ratio of (20-24):64:(2-3):(9-14) by weight to form the slurry.

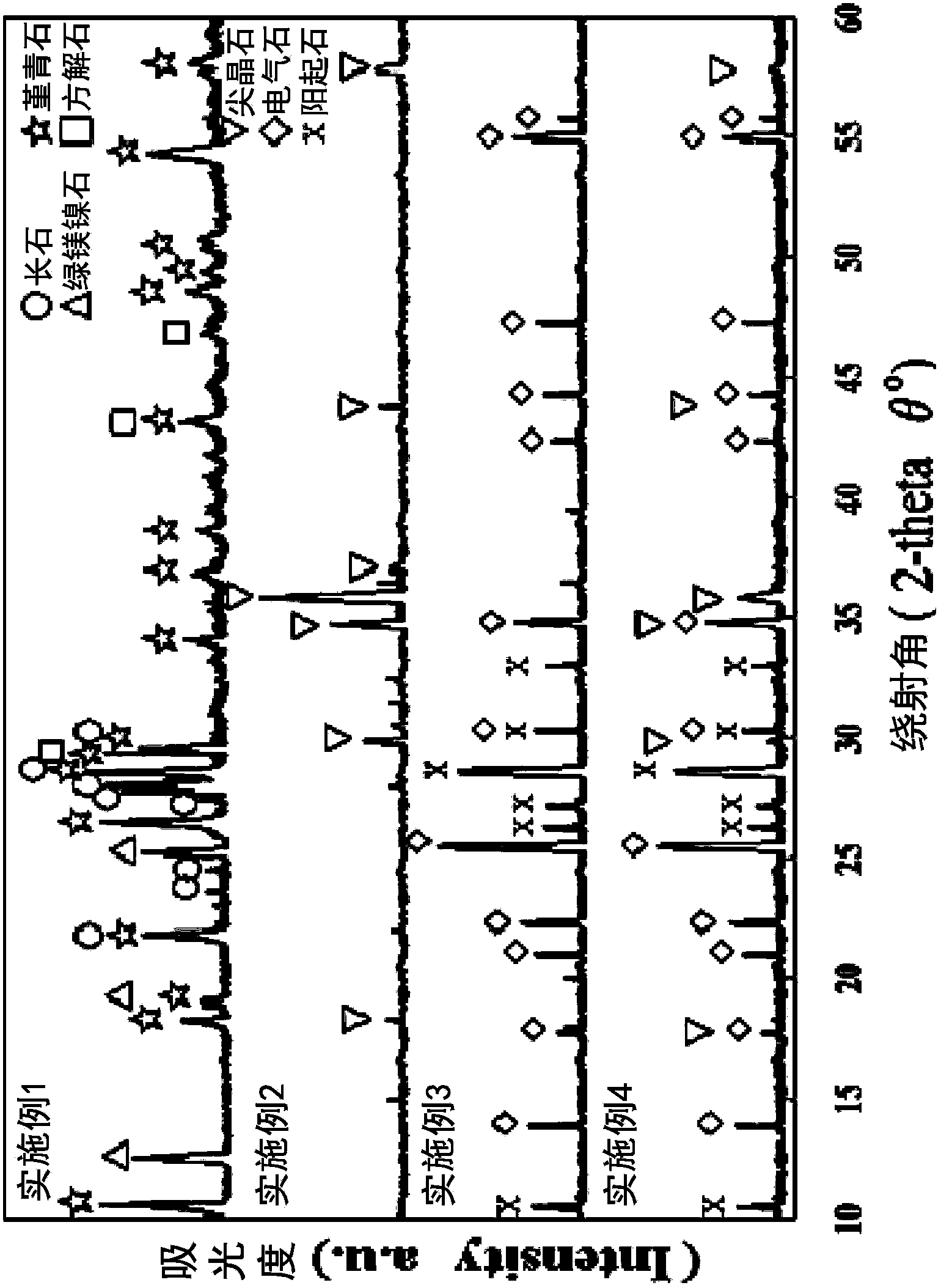

[0054] Further, the slurry is coated on the transfer surface of a substrate, and then dried to form a film with far-infrared radiation function. Please refer to figure 2 . As shown in the figure, the X-ray diffractometer is used to analyze the composition phase of the film as a composite structure of Calcite, Anorthite, Alipite and Cordierite. The molecular formulas of the components ...

Embodiment 2

[0056] Transition metal salts such as MnCl in varying proportions 2 (20~40%), FeCl 3 (20~40%), CoCl 2 ·6H 2 O (≦10%), NiCl 2 ·6H 2 O(≦10%) and CuCl 2 (10-20%) uniformly mixed, sintered at a high temperature of 1000-1400 ° C to form a ceramic powder precursor, and kept at a constant temperature for about 8 hours, and ground to a micron-level fineness for later use. The ceramic powder precursor, ethanol, polymer Vinyl butyral and butylene oxide are mixed and stirred at a ratio of (15-19):73:(3-4):(4-9) by weight to form the slurry.

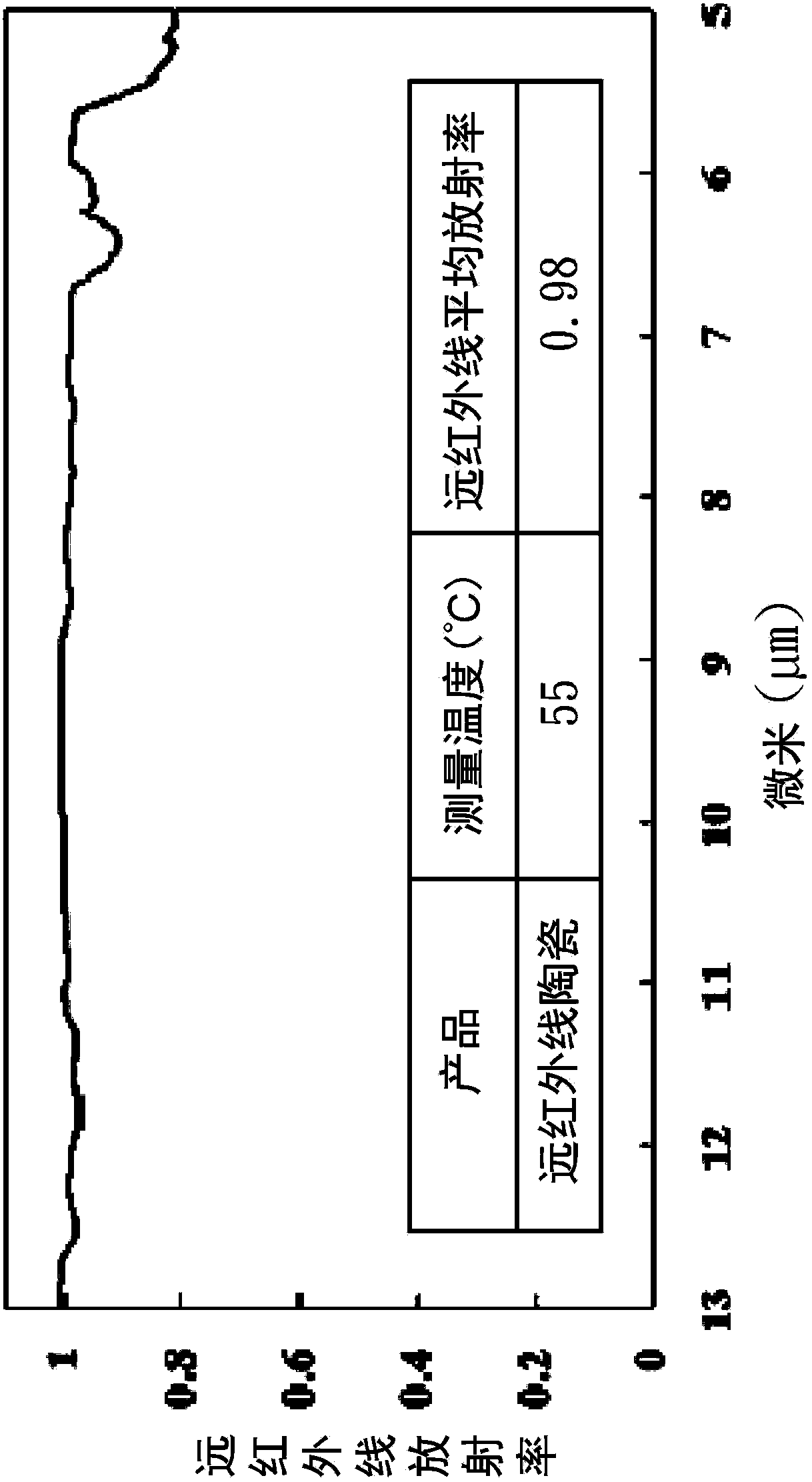

[0057] Further, the slurry is coated on the transfer surface of a substrate, and then dried to form a film with far-infrared radiation function. Please refer to figure 2 . As shown in the figure, the X-ray diffractometer is used to analyze the structure of the film composition phase as spinel (Spinel), and the molecular formula of the composition is AB 2 o 4 , where A=Cu, Co, Ni, Mn or Fe; B=Cu, Co, Ni, Mn or Fe. Using Fourier transform ...

Embodiment 3

[0059] Salts of Na, Mg, Ca, Al, Cu, Fe or B in different proportions, such as AlCl 3 (10~30%), MgCl 2 ·6H 2 O (5~15%), CaCl 2 ·6H 2 O (10~30%), Na 2 SiO 3 9H 2 O(35~65%), CuCl 2 (≦13%), FeCl 3 (≦13%) and H 3 BO 3 (5-25%) were dissolved in deionized water and hydrochloric acid respectively, and then phenolic resin (2%) was added according to the weight percentage and evenly mixed and stirred to form the far-infrared heat dissipation ceramic slurry.

[0060] Next, a substrate is preheated at about 300-900° C., and then the slurry is sprayed on the transfer surface of the substrate, thermally decomposed and sintered to form a film with far-infrared radiation function. Please refer to figure 2 . As shown in the figure, the X-ray diffractometer was used to analyze the composition phase of the film as a composite structure of actinolite (Actinolite) and tourmaline (Tourmaline), and the molecular formulas of the components were Ca 2 E. 5 [Si 4 o 11 ] 2 (OH) 2 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com