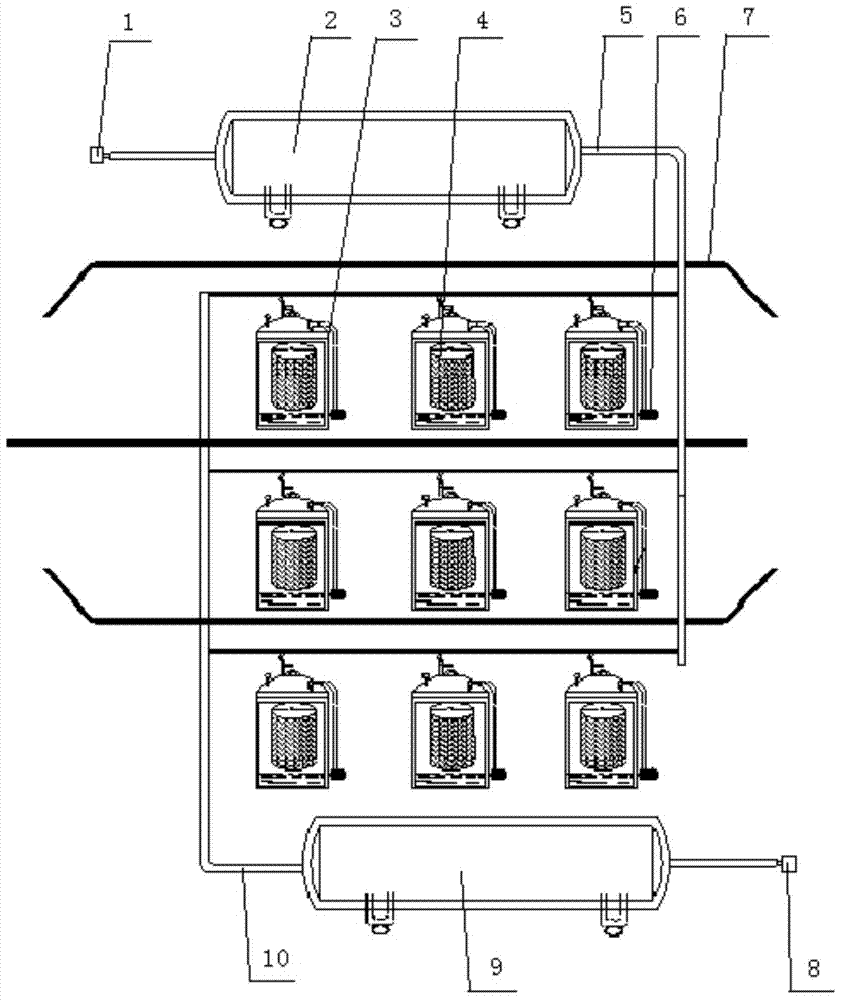

Method for continuously and rapidly producing reformed egg through vacuum pressure reduction and back pressure interaction method and pickling system

A technology for vacuum decompression and egg reprocessing, applied in the field of food science, can solve the problems of hindering new technology of preserved egg processing, uncontrollable production process, long production cycle of raw eggs, etc. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

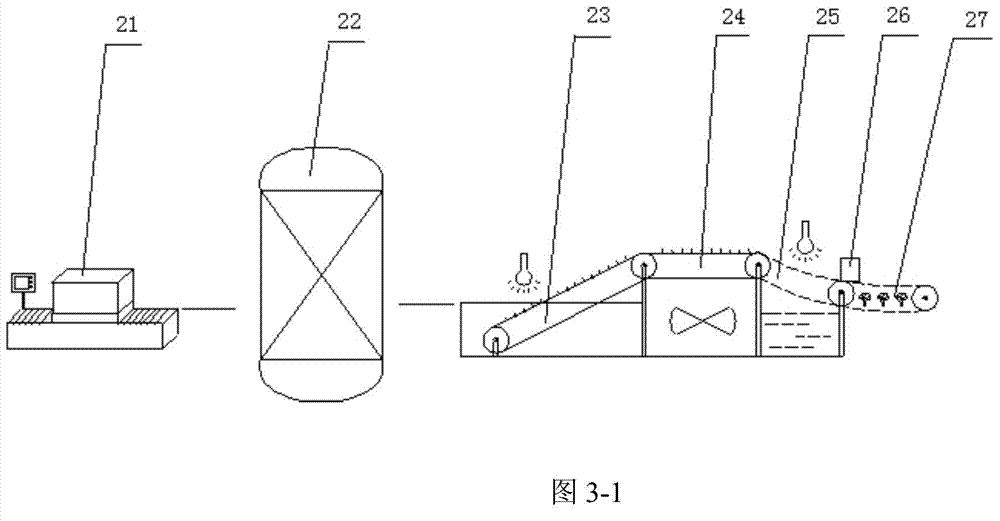

[0063]A method for continuous rapid production of salted eggs by vacuum decompression and back pressure interactive method, the specific steps are as follows:

[0064] ⑴Material selection: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other bad eggs, wash them with an egg washing machine, dry them in the air or blow them in the air.

[0065] (2) Basic preparation of feed solution: add NaCl, KCl and white wine to the water, stir fully to dissolve them all, let the feed solution air to room temperature for later use, NaCl in the solution accounts for 7% of the total mass of the solution, KCl accounts for 7% of the total mass of the solution %, liquor accounted for 2% of the total mass of the solution.

[0066] In this step, the penetration speed of the feed liquid is related to the concentration of the feed liquid, and the concentration of the feed liquid cannot be too high or too low. The thickness of the eggshell and the quality of ...

Embodiment 2

[0072] A method for rapidly producing salted preserved eggs by using a vacuum decompression and back pressure interactive pickling machine alone, the specific steps are as follows:

[0073] ⑴Material selection: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other bad eggs, wash them with cold boiled water or disinfectant water, and then dry them with an egg washing machine, dry them in the air or blow them in the air.

[0074] ⑵Basic preparation of feed liquid: boil tea leaves, Chinese prickly ash, star anise, cardamom, fennel, fragrant leaves and cloves with water, filter, add salt and soda ash to the filtrate, stir well to dissolve them all, and let the feed liquid dry to room temperature for later use. , 4.5% tea, 2.5% pepper, 2% star anise, 2% cardamom, 2% fennel, 1% fragrant leaves, and 1% cloves.

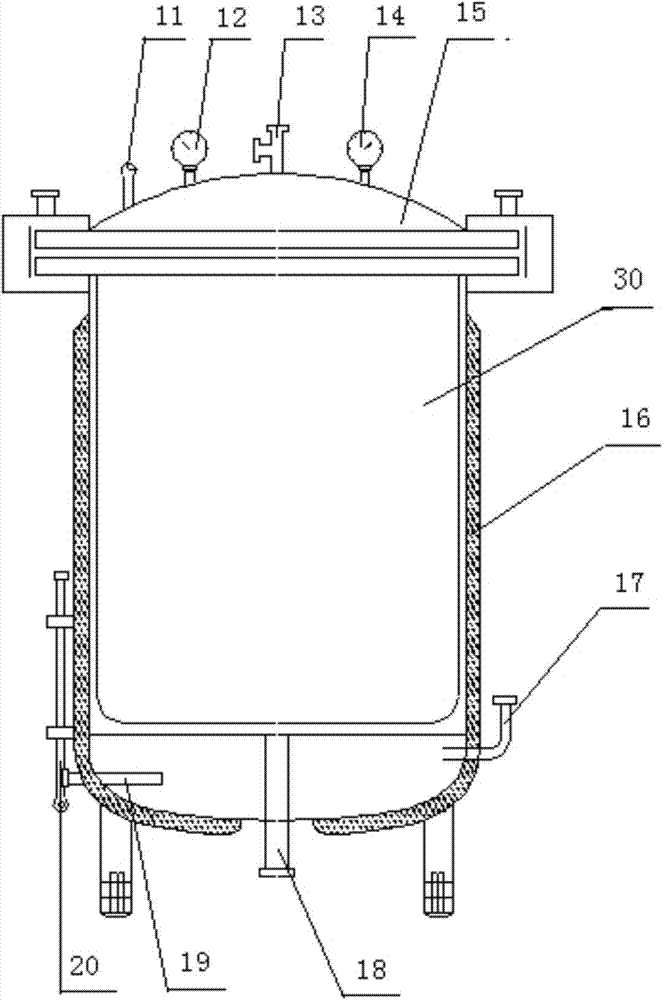

[0075] ⑶ Placement of duck eggs: Put the selected duck eggs in plastic egg boxes, then put the egg boxes into stainless steel egg b...

Embodiment 3

[0080] A method for continuous rapid production of preserved eggs by vacuum decompression and back pressure interactive method, the concrete steps are as follows:

[0081] ⑴Material selection: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other bad eggs, wash them with an egg washing machine, dry them in the air or blow them in the air.

[0082] (2) Basic preparation of feed liquid: add 1000mL of water to 25g of black tea powder and 25g of fresh cypress leaves and boil, filter out the tea leaves and fresh cypress branches, add NaOH45g, NaCl50g, CuSO 4 4g, stir well to dissolve it completely, and let the material solution air to room temperature for later use.

[0083] ⑶ Placement of duck eggs: Put the selected duck eggs in plastic egg boxes, and then put the egg boxes into stainless steel egg boxes.

[0084] ⑷Vacuum decompression and back pressure interactive treatment: the egg carton is sent into the curing box filled with the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com