Method for fast confirming compact rock core damage

A core and dense technology, applied in the field of quickly determining the damage of dense cores, can solve the problems of time-consuming, large errors, and high requirements for experimental equipment, and achieve the effects of difficult measurement, rapid damage, and easy evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

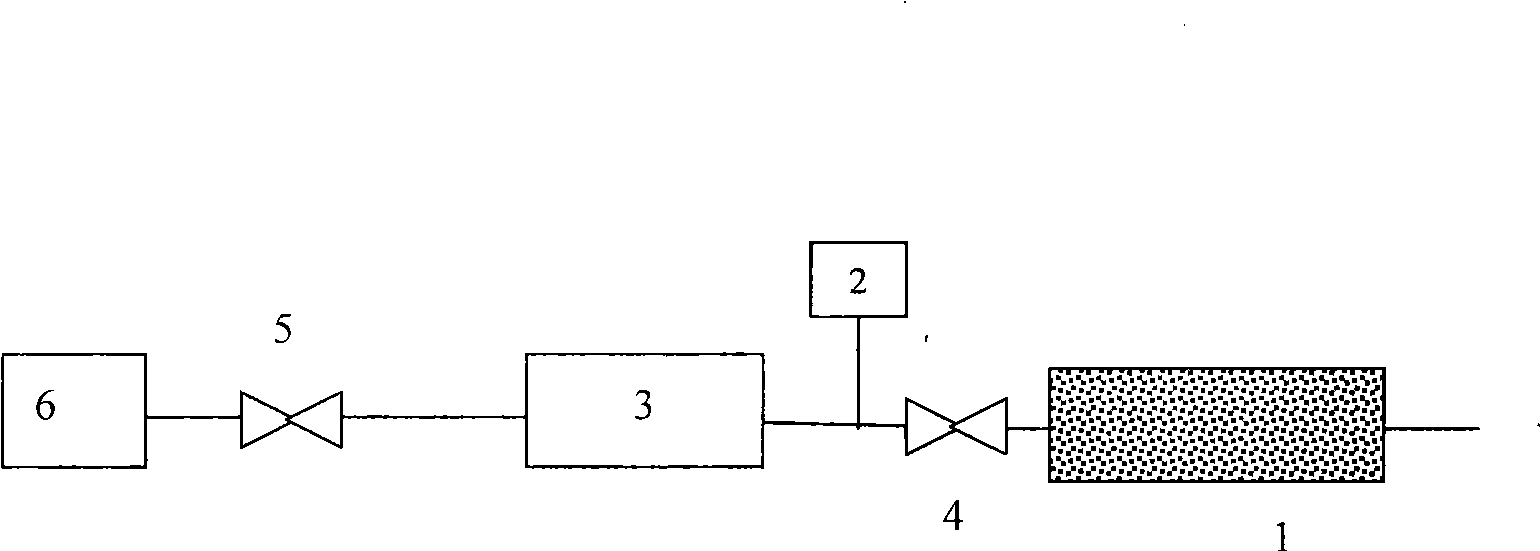

Method used

Image

Examples

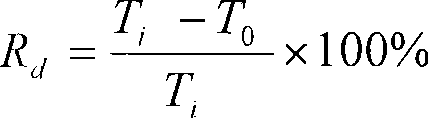

Embodiment 1

[0042] Two tight sandstone cores with similar lithology and physical properties in western Sichuan outcrop were selected to evaluate the damage degree of distilled water to the cores by the invented method. The experimental results show that the permeability is 0.115×10 -3 μm 2 Under the confining pressure of 3MPa, the pressure half-life of the 3% KCl solution and the initial pressure of distilled water 0.8MPa are 285min and 375min respectively, and the damage rate calculated by the inventive method is 24%; the other piece has a permeability of 0.1×10 -3 μm 2 Under the confining pressure of 3MPa, the pressure half-life of the 3% KCl solution and the initial pressure of distilled water at 0.8MPa are 375min and 525min respectively, and the damage rate calculated by the inventive method is 28.57%. Distilled water has weak damage to the two cores with similar lithology and physical properties.

Embodiment 2

[0044] Two tight sandstone cores with similar lithology and physical properties in outcrops in western Sichuan were selected to evaluate the damage degree of alkali solution to the cores by the method of the invention. The experimental results show that the permeability is 0.094×10 -3 μm 2 Under the confining pressure of 3MPa, the pressure half-life of 3% KCl solution and 3% KCl solution with a pH value of 13 (that is, adding lye to 3% KCl solution) at an initial pressure of 0.8MPa is 375min and 405min respectively, The damage rate calculated by the inventive method is 7.41%; the other block has a permeability rate of 0.075×10 -3 μm 2 Under the confining pressure of 3MPa, the pressure half-life of 3% KCl solution and 3% KCl solution with a pH value of 13 at an initial pressure of 0.8MPa are 405min and 435min respectively, and the damage rate calculated by the inventive method is 6.90%. The lye with a pH value of 13 has weak damage to the two cores with similar lithology and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com