Preparation equipment, preparation method and application of thallus compound amino acid feed additive

A compound amino acid and feed additive technology, applied in application, animal feed, animal feed, etc., can solve the problems of sludge without harmless treatment, human health hazards, and surrounding environmental pollution, and achieve systematic treatment and solution The effect of waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

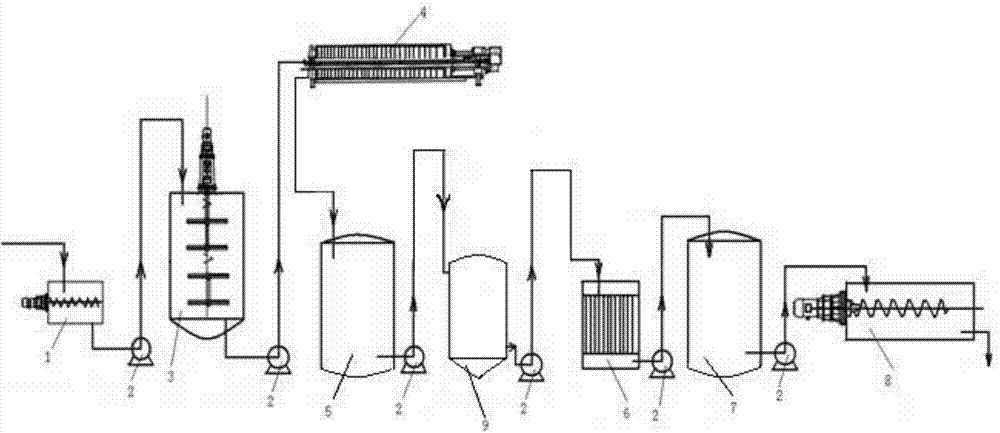

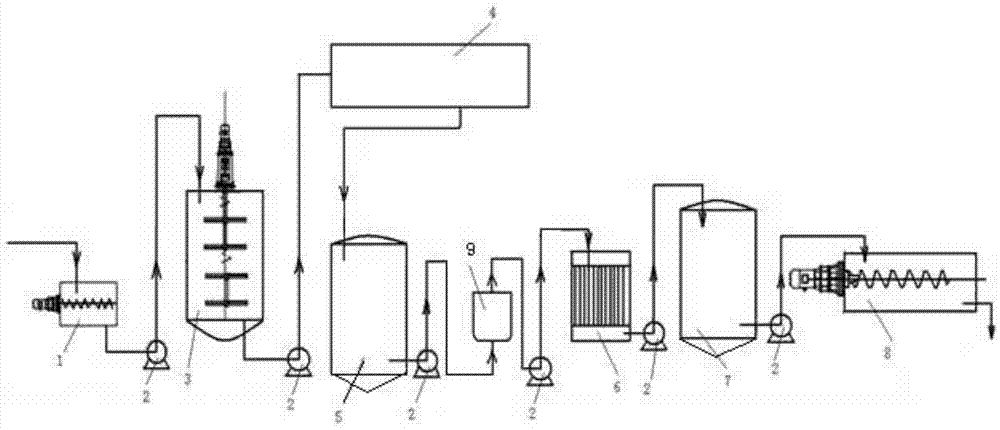

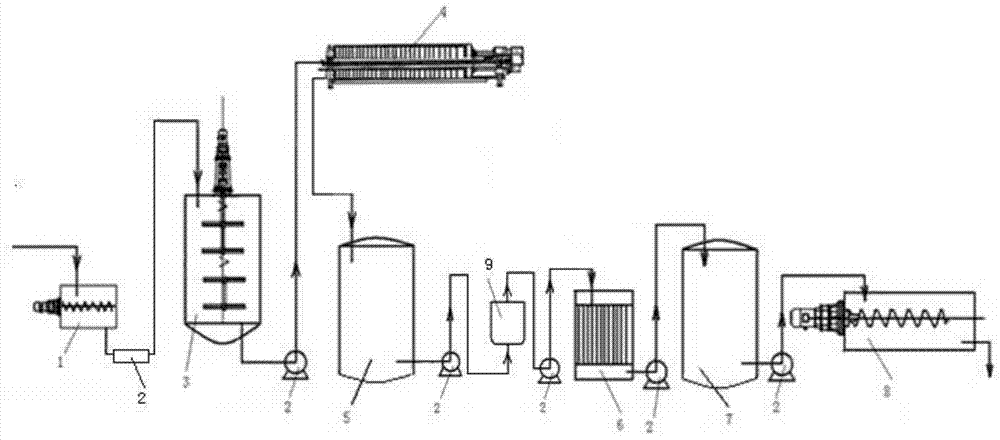

Image

Examples

Embodiment 1

[0035] The present invention provides a method for preparing the bacterium compound amino acid feed additive by utilizing the preparation equipment of the bacterium compound amino acid feed additive, comprising the following specific steps:

[0036] (1) After crushing the microbial residue, hydrolyze it under alkaline conditions. The hydrolysis conditions are: PH value is 10, hydrolysis temperature is 125°C, reaction pressure is 0.2MP, and hydrolysis time is 5 hours;

[0037] The hydrolysis reactant was subjected to solid-liquid separation, the filtrate was collected, and the pH value of the filtrate was adjusted to 6.5 with nitric acid.

[0038] The microbial residues in this example are taken from algae blooms in the waters of Taihu Lake, with a water content of 95% and a crude protein content of about 30% on a dry basis.

[0039] (2) Use one of the ultrafiltration membrane filtration devices, that is, a ceramic membrane filter to remove impurities in the filtrate with a pH ...

Embodiment 2

[0045] The invention provides a method for preparing the bacterial compound amino acid feed additive by using the preparation equipment of the bacterial compound amino acid feed additive, comprising the following specific steps:

[0046] (1) After crushing the microbial residue, hydrolyze it under alkaline conditions. The hydrolysis conditions are: PH value is 9, hydrolysis temperature is 110°C, reaction pressure is 0.25MP, and hydrolysis time is 10 hours;

[0047] The hydrolyzed reactant was subjected to solid-liquid separation, the filtrate was collected, and the pH value of the filtrate was adjusted to 5 with hydrochloric acid.

[0048] The microbial residues in this example were taken from the alcoholic fermentation waste liquid of a winery, with a water content of 99% and a crude protein content of about 25% on a dry basis.

[0049] (2) Using a centrifuge to remove impurities in the filtrate with a pH of 5 obtained in step (1), and using a reverse osmosis membrane filter ...

Embodiment 3

[0055] The invention provides a method for preparing the bacterial compound amino acid feed additive by using the preparation equipment of the bacterial compound amino acid feed additive, comprising the following specific steps:

[0056] (1) After crushing the microbial residue, hydrolyze it under alkaline conditions. The hydrolysis conditions are: PH value is 13, hydrolysis temperature is 130°C, reaction pressure is 0.28MP, and hydrolysis time is 2 hours;

[0057] The hydrolyzed reactant was subjected to solid-liquid separation, and the pH value of the filtrate was adjusted to 9 with sulfuric acid.

[0058] The microbial residues in this example were taken from the activated sludge of Xinhe Sewage Treatment Co., Ltd., Tanggu District, Tianjin, with a water content of 80% and a crude protein content of about 23% on a dry basis.

[0059] (2) Using a centrifuge to remove impurities in the filtrate with a pH of 9 obtained in step (1), and using an electrodialysis machine to remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com