Raw material pretreatment method for preparing biogas

A pretreatment and raw material technology, which is applied in the direction of biomass pretreatment, biomass post-treatment, biological sludge treatment, etc., can solve the problems of low biogas fermentation gas production, lack of biogas raw material treatment methods and treatment devices, etc., and achieve the goal of improving biogas speed, increased utilization, and reduced acidification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

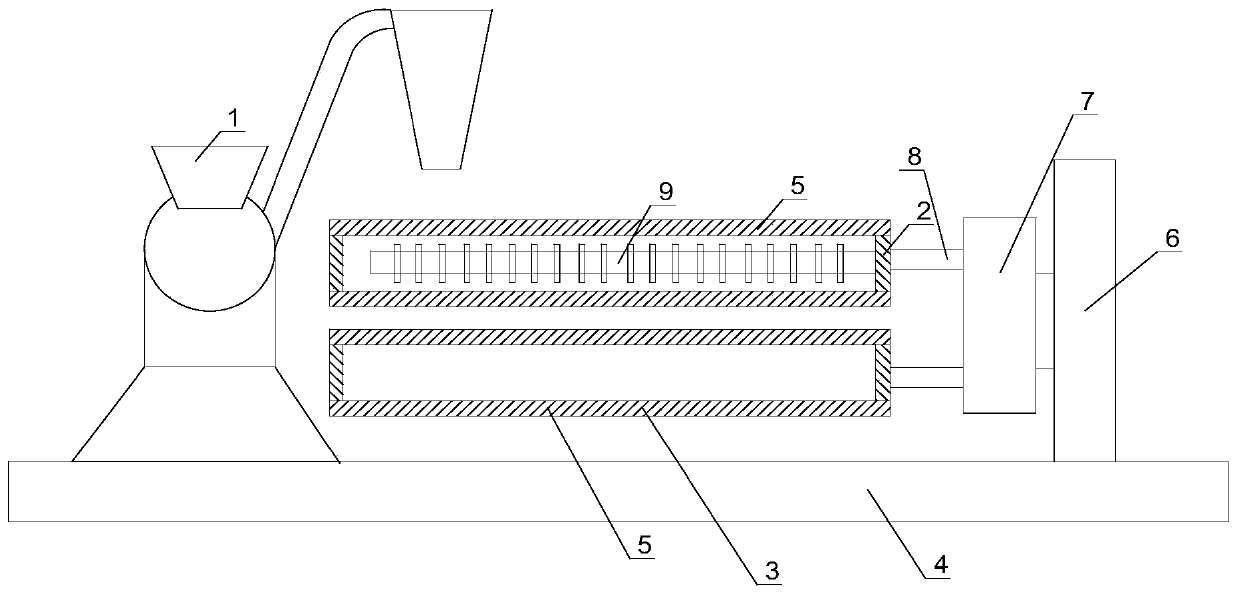

[0031] Such as figure 1 Shown, a kind of raw material pretreatment method for producing biogas of the present invention comprises the following steps:

[0032] S1. Obtain solid raw materials for biogas fermentation. The solid raw materials are dried in a drying device, and after drying, they are subjected to grit treatment in a grit chamber to remove sand and stones in the solid raw materials. The solid raw materials are desanded and then dried;

[0033] S2. In the pre-fermentation device, the solid raw material dried after desanding in step S1 is pulverized and mixed. The pre-fermentation device includes a pulverizer 1 and a mixing tank 2. The solid raw material is pulverized in the pulverizer 1 and then transferred to the mixing tank. In the tank 2, the pulverized solid material and the liquid fermentation material after desanding are uniformly mixed in the mixing tank 2, and the liquid fermentation material fully wets the solid material to obtain a wet mixed fermentation ma...

Embodiment 2

[0038] Based on Example 1, the pre-fermentation device also includes a horizontally placed base 4, the pulverizer 1, the mixing tank 2, and the stacking retting tank 3 are all installed on the base 4, and the mixing tank 2 and the stacking retting tank 3 adopt shapes and For tanks with the same size, the top and bottom surfaces of the tank are provided with openings, the top and bottom of the tank are provided with cover plates 5 for blocking the openings, and the covers on the mixing tank 2 and the retting tank 3 The plates are detachably connected to the corresponding mixing tank 2 and retting tank 3, the mixing tank 2 and the retting tank 3 are parallel to each other in the vertical direction and the vertical bisectors of the mixing tank 2 and the retting tank 3 coincide, A vertical mounting plate 6 is installed on the base 4, and the mounting plate 6 is located on one side of the mixing tank 2 and the retting tank 3, and the mounting plate 6 is installed with a rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com