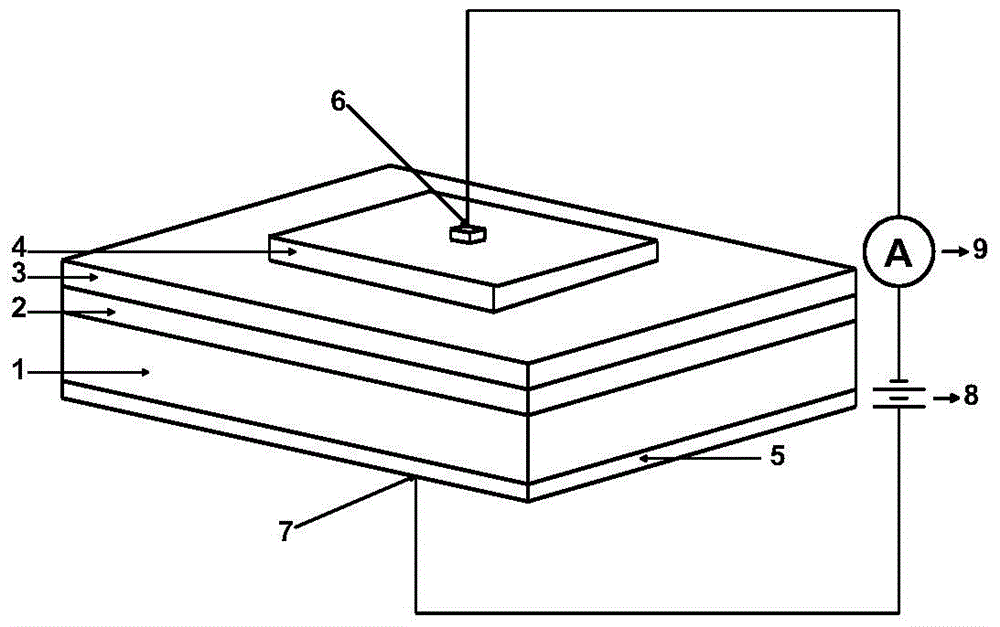

Palladium/titanium dioxide/silicon dioxide/silicon heterojunction-based hydrogen detector

A technology of titanium dioxide and silicon dioxide is applied in the field of hydrogen detectors to achieve the effects of low energy consumption, high sensitivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Titanium dioxide sputtering targets were obtained by cold pressing titanium dioxide powder with a purity (mass fraction) of 99.99%. We selected a monocrystalline silicon wafer with a thickness of 0.5 mm as the substrate, and retained its natural oxide layer. Clean the silicon wafer with ethanol and acetone in ultrasonic wave for 5 minutes, and clean the silicon wafer with deionized water for 1 minute.

[0029] Titanium dioxide film was prepared by radio frequency magnetron sputtering: put the cleaned silicon substrate into the sputtering chamber, and turn on the vacuum system for vacuuming; when the background vacuum was 2×10 -4 When the pressure is Pa, argon / oxygen mixed gas is introduced, the ratio of the two gases is between 2:1 and 1:2, and a pressure of 5 Pa is maintained. After the pressure is stable, start sputtering with a titanium dioxide target, and the RF sputtering power The sputtering time is 90 watts, the sputtering time is 30 seconds, and the sputtering ...

Embodiment 2

[0034] Titanium dioxide sputtering targets were obtained by cold pressing titanium dioxide powder with a purity (mass fraction) of 99.99%. We selected a monocrystalline silicon wafer with a thickness of 0.5 mm as the substrate, and retained its natural oxide layer. Clean the silicon wafer with ethanol and acetone in ultrasonic wave for 5 minutes, and clean the silicon wafer with deionized water for 1 minute.

[0035] Titanium dioxide film was prepared by radio frequency magnetron sputtering: put the cleaned silicon substrate into the sputtering chamber, and turn on the vacuum system for vacuuming; when the background vacuum was 2×10 -4 When the pressure is Pa, argon / oxygen mixed gas is introduced, the ratio of the two gases is between 2:1 and 1:2, and a pressure of 5 Pa is maintained. After the pressure is stable, start sputtering with a titanium dioxide target, and the RF sputtering power The sputtering time is 90 watts, the sputtering time is 60 seconds, and the sputtering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com