Fluid loss agent for high-temperature-resistant compound salt resistant polymer for drilling fluid and preparation method thereof

A water loss reducing agent and anti-high temperature technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor salt resistance and high temperature resistance, achieve good salt and calcium resistance, and reduce fluid loss , Reduce the effect of sticking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

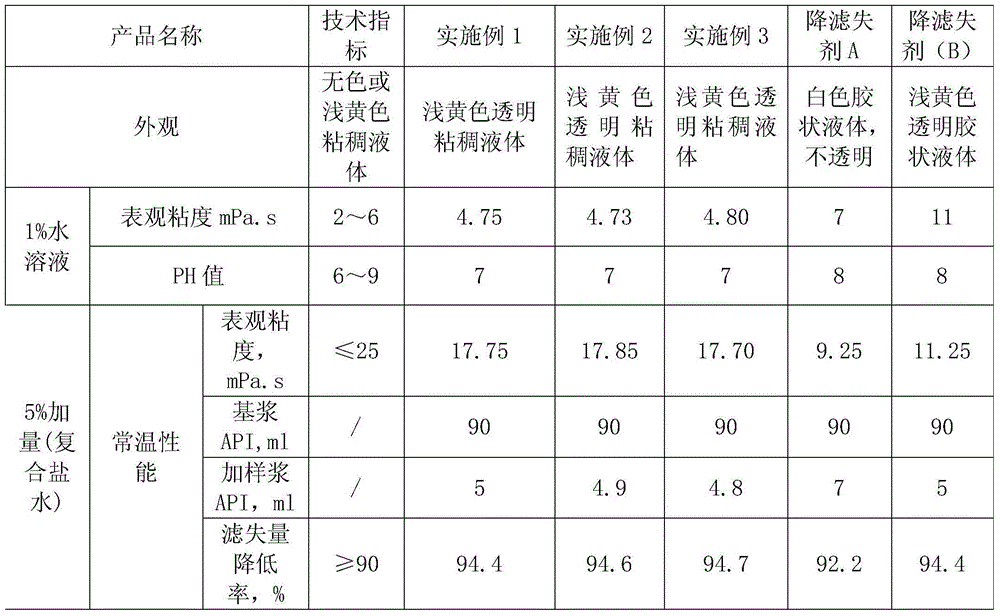

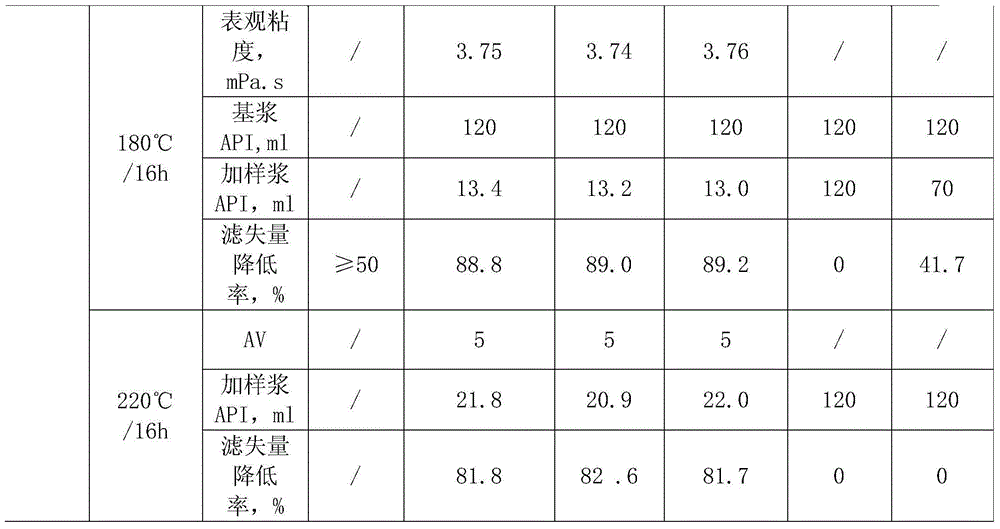

Examples

Embodiment 1

[0027] 1.1 A fluid loss reducing agent for high temperature and compound salt polymers for drilling fluids, which consists of the following raw materials in percentage by weight: 12.2% acrylic acid, 7.2% sodium hydroxide, 62.3% deionized water, 5.5% acrylamide, four Sodium styrene sulfonate 5.5%, N-vinylpyrrolidone 7%, initiator 0.3%.

[0028] Prepare 1000kg of water loss reducing agent for high temperature and compound salt polymer used in drilling fluid of the present invention, specific raw materials and consumption are: 122kg of acrylic acid, 72kg of sodium hydroxide, 623kg of deionized water, 55kg of acrylamide, tetraphenylethylene sulfonic acid 55kg of sodium, 7kg of N-vinylpyrrolidone, and 3kg of initiator, wherein the initiator is 1.5kg of ammonium persulfate and 1.5kg of sodium sulfite.

[0029] 1.2 Preparation steps:

[0030] (1) Add 130kg deionized water into the reaction kettle, stir, add ammonium persulfate and sodium sulfite, stir for 0.5h, pump into the meterin...

Embodiment 2

[0034] 2.1 A fluid loss reducing agent for high temperature and compound salt polymers for drilling fluids, which consists of the following raw materials in percentage by weight: 12.0% acrylic acid, 7.0% sodium hydroxide, 62.0% deionized water, 7.0% acrylamide, four Sodium styrene sulfonate 5.3%, N-vinylpyrrolidone 6.5%, initiator 0.2%.

[0035] Prepare 1000 kg of fluid loss reducing agent for high temperature and anti-compound salt polymer for drilling fluid of the present invention, specific raw materials and consumption are: 120 kg of acrylic acid, 70 kg of sodium hydroxide, 620 kg of deionized water, 70 kg of acrylamide, tetraphenylethylene sulfonic acid Sodium 53kg, N-vinylpyrrolidone 65kg, initiator 2kg, wherein initiator is potassium persulfate 1kg, sodium bisulfite 1kg.

[0036] 2.2 Preparation steps:

[0037] (1) Add 186kg of deionized water into the reaction kettle, stir, add potassium persulfate and sodium bisulfite, stir for 0.5h, pump into the metering tank for u...

Embodiment 3

[0041] 3.1 A fluid loss reducing agent for high temperature and compound salt polymers for drilling fluids, which consists of the following raw materials in percentage by weight: 15.0% acrylic acid, 8.5% sodium hydroxide, 60.0% deionized water, 4.0% acrylamide, four Sodium styrene sulfonate 5.6%, N-vinylpyrrolidone 6.5%, initiator 0.4%.

[0042]Prepare 1000kg of water loss reducing agent for high temperature and anti-compound salt polymer for drilling fluid of the present invention, the specific raw materials and consumption are: 150kg of acrylic acid, 85kg of sodium hydroxide, 600kg of deionized water, 40kg of acrylamide, tetraphenylethylene sulfonic acid Sodium 56kg, N-vinylpyrrolidone 65kg, initiator 4kg, wherein initiator is ammonium persulfate 2kg, sodium bisulfite 2kg.

[0043] 3.2 Preparation steps:

[0044] (1) Add 150kg deionized water into the reaction kettle, stir, add potassium persulfate and sodium bisulfite, stir for 0.5h, pump into the metering tank for use;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com