42 kg-level titania type carbon steel covered electrode and preparation method thereof

A titanium-type carbon steel electrode, kilogram-level technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as price increase, impact on enterprise economic benefits, increase in electrode production costs, etc., to reduce energy consumption and reduce body weight Hazards, effects of secondary arc ignition performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

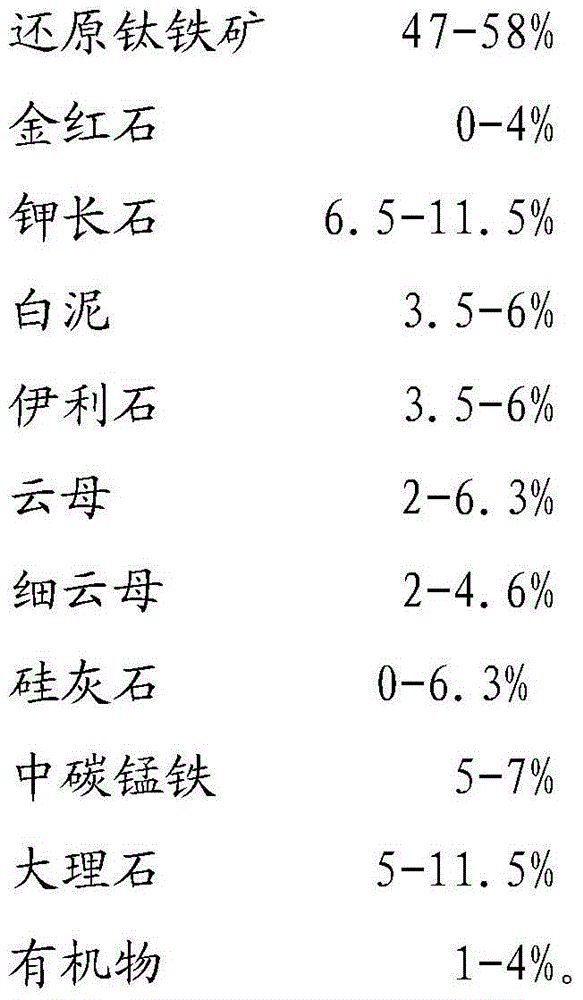

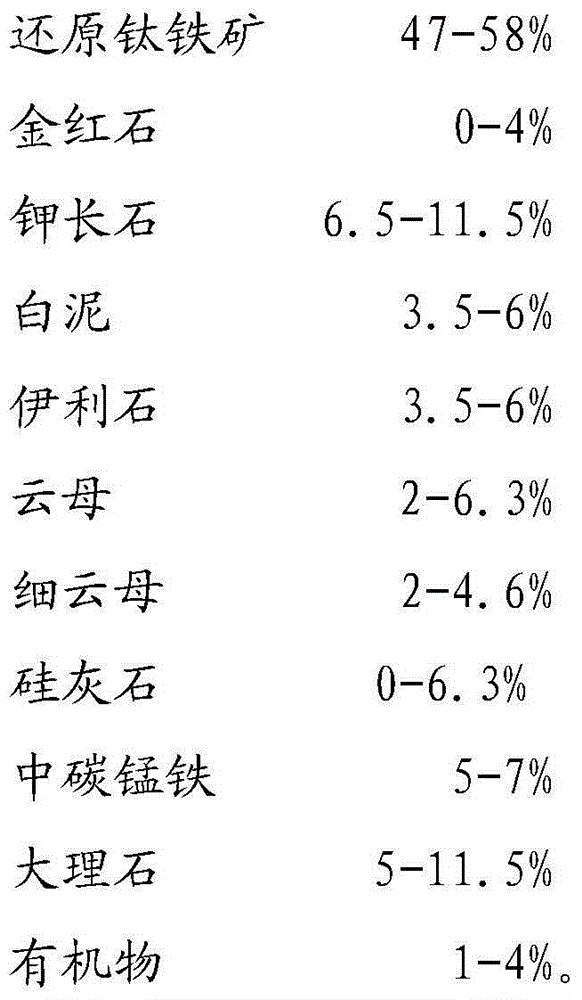

Method used

Image

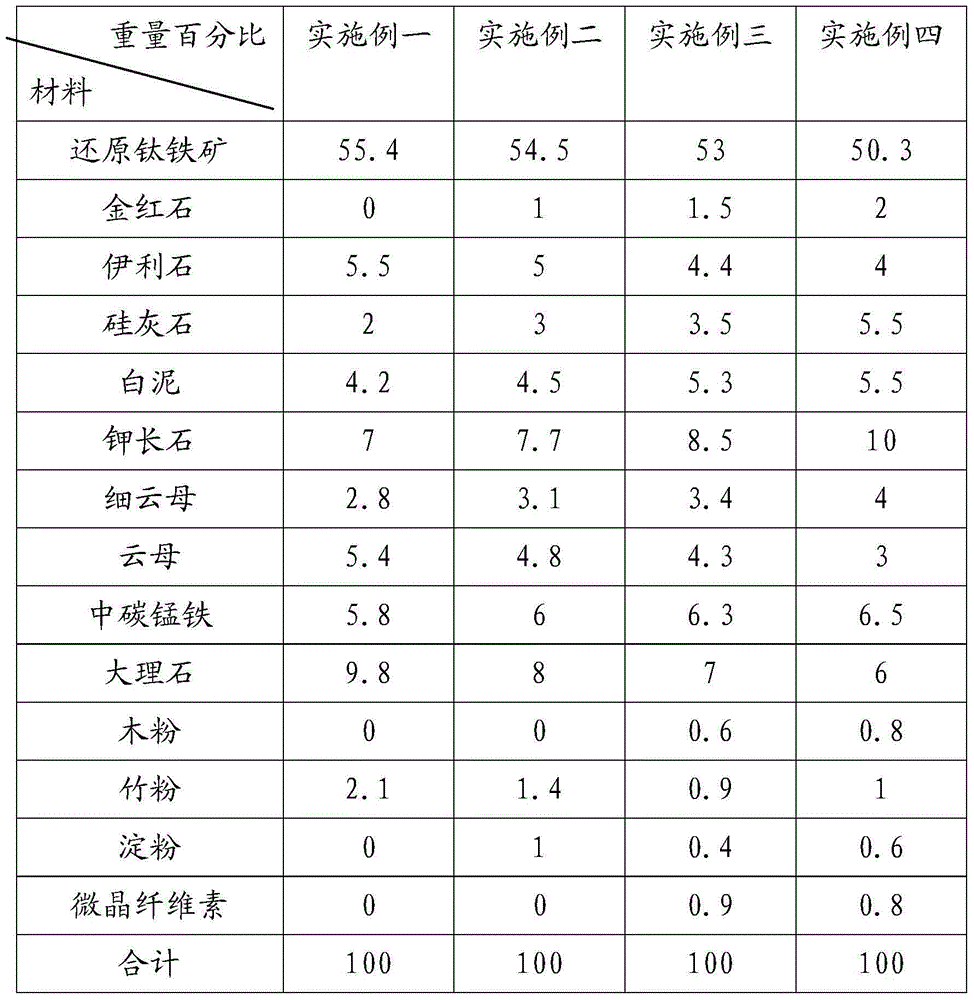

Examples

preparation example Construction

[0026] The preparation method of the above 42 kg titanium carbon steel electrode includes the following steps: take various materials according to the stated ratio and mix them evenly, adopt spiral electrode production equipment, use modulus 2.3-2.8, potassium sodium ratio 2.5-4 : 1. Potassium-sodium mixed water glass with a concentration of 37-40° Baume is used as a binder. The addition amount is 18-25% of the weight of the mixed powder. After stirring, use the spiral electrode production equipment to evenly coat the different diameters. On the welding core; after grinding the clamping end and the arc starting end, use a welding rod drying furnace to dry at a low temperature of 45-90℃, a medium temperature of 90-130℃, and a high temperature of 130-180℃ to prepare reduced titanium iron Mine type 42 kg titanium type carbon steel acid electrode.

[0027] The preparation method of the 42 kg titanium carbon steel electrode includes the following steps: take various materials accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com