Protection film for high-power concentrating photovoltaic system receiver and production method thereof

A photovoltaic system and high-power concentrating technology, applied in photovoltaic power generation, semiconductor devices, and final product manufacturing, etc., can solve the problems of receiver damage, bubbles susceptible to thermal expansion, control film uniformity and thickness, etc. The effect of accelerating heat transfer and preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

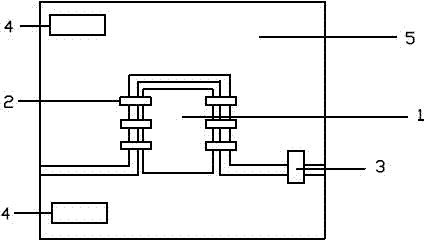

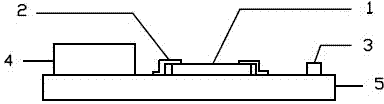

[0026] Such as figure 1 As shown, the receiver of the conventional structure includes a GaAs stacked solar cell 1, a gold wire 2 for bonding, a Schottky diode 3, a cable interface 4, and a copper-clad ceramic plate 5. Taking this receiver as an example, the following methods are combined: Implement the present invention:

[0027] Step 1: Place the receiver on the sample holder in the vacuum chamber of the atomic layer deposition (ALD) equipment. The vacuum degree of the vacuum chamber is kept at 600-800pa, and the chamber temperature is room temperature;

[0028] Step 2: Pass the metal organic precursor trimethylaluminum (TMAl) into the vacuum chamber, the metal organic matter forms adsorption on the surface of the receiver, control the adsorption reaction time for 0.1~0.3 seconds, and then pass nitrogen gas into the vacuum chamber for blowing Sweeping, the sweeping time is 1~2 seconds;

[0029] Step 3: Pass the second precursor water vapor, and the water vapor will further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com