X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

A technology of straight seam submerged arc welding and stress corrosion, which is applied in the field of welding to achieve the effects of excellent formability and degassing, high purity and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

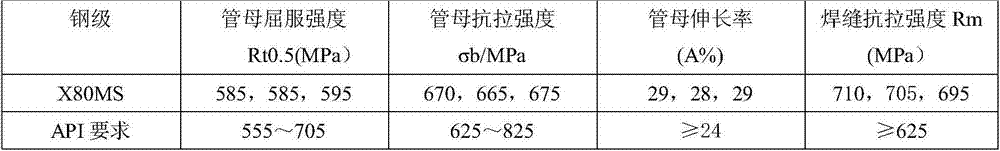

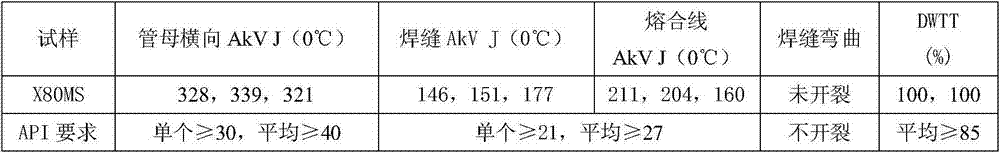

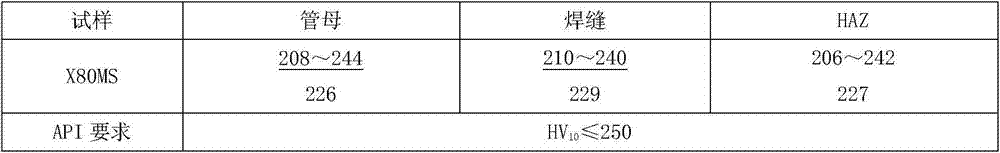

[0045] Example 1: Manufacture of Ф813×15.3mmX80MS steel grade hydrogen sulfide corrosion resistant longitudinal submerged arc welded pipe

[0046] 1) Raw material

[0047] The X80MS steel plate with a wall thickness of 15.3 mm is used, and its chemical composition analysis is as follows in Table 1:

[0048] Table 1X80MS chemical composition analysis (%)

[0049] C

Si

mn

P

S

Cr

Cu

Ni

Mo

Nb

Ti

Al

B

Ca

0.032

0.29

1.59

0.007

0.0009

0.09

0.11

0.17

0.22

0.06

0.07

0.07

0.0003

0.0008

[0050] 2) Edge milling and pre-bending of the steel plate: after edge milling, the angle of the upward groove is 80°, the angle of the downward groove is 75°, and the height of the blunt edge is 6mm;

[0051] 3) After the milled steel plate is centered on the roller table, the steel plate is deformed to meet the radian requirements of the forming process design through the ext...

Embodiment 2

[0077] Example 2: Manufacture of Ф813×17.5mm X80MS steel grade hydrogen sulfide corrosion resistant longitudinal submerged arc welded pipe

[0078] 1) Raw material

[0079] The X80MS steel plate with a wall thickness of 17.5mm is used, and its chemical composition is analyzed in the following table:

[0080] Table 7: X80MS chemical composition analysis

[0081] C

Si

mn

P

S

Cr

Cu

Ni

Mo

Nb

Ti

Al

B

Ca

0.032

0.30

1.58

0.007

0.0009

0.09

0.12

0.17

0.23

0.06

0.07

0.06

0.0003

0.0007

[0082] 2) Steel plate edge milling and pre-bending: after edge milling, the angle of the up groove is 100°, the angle of the down groove is 80°, and the height of the blunt edge is 8mm;

[0083] 3) After the milled steel plate is centered on the roller table, the steel plate is deformed to meet the radian requirements of the forming process design through the extrusion of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com