Epoxy resin adhesive used for encapsulating smart cards

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, novolak epoxy resin adhesive, adhesive, etc., which can solve the problem of low wire bonding yield, too thin adhesive layer, and module thickness not meeting the requirements and other issues, to achieve the effect of improving the wire bonding yield and efficiency, reducing the height difference of the four corners, and improving the wire bonding yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

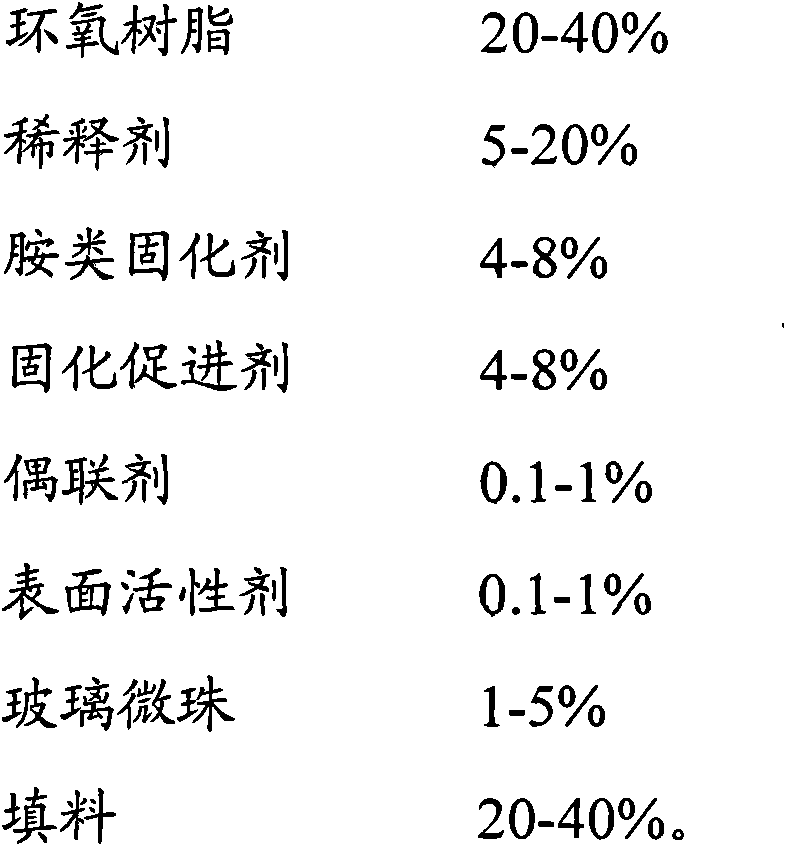

[0025] The formula is:

[0026]

[0027] Preparation method: mix bisphenol A epoxy resin, 92% 1,4-butanediol diglycidyl ether, dicyandiamide, 2-methylimidazole, aminopropyltriethoxysilane and silane surfactant according to dosage Mix evenly, mix twice through a three-roller machine, then add silicon micropowder, stir evenly, then mix both sides through a three-roller machine, then add glass microspheres, stir for half an hour, and vacuum defoam for 30 minutes to obtain the non-conductive epoxy resin adhesive.

[0028] Take 0.5ml adhesive to test its viscosity: 25°C viscosity is 10000Cp; thixotropic index is 5.2; 150°C 3min glue can be cured; 2*2mm chip, Ag / Cu frame can withstand horizontal shear force of more than 15kg at 25°C; curing The resin overflow measurement before is 0, and the resin overflow is 0 after curing; the thickness of the adhesive layer is 10-15 microns, and the height difference of the four corners is up to 6um. Obviously, the performance of the epoxy r...

Embodiment 2

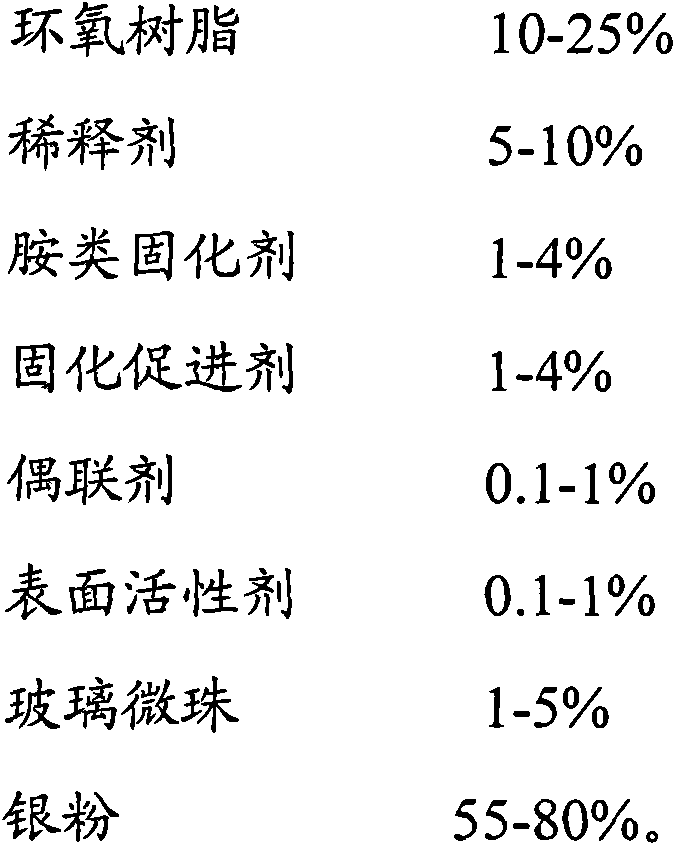

[0030] The formula is:

[0031]

[0032] Preparation method: mix bisphenol F epoxy resin, 92% 1,4-butanediol diglycidyl ether, polyetheramine, 2-ethylimidazole, propyltrimethoxysilane and silane surfactant according to dosage Evenly, mix twice through a three-roll machine, then add polytetrafluoroethylene micropowder, stir evenly, then mix both sides through a three-roll machine, then add glass microspheres, stir for half an hour, and vacuum defoam for 30 minutes to obtain the present invention Non-conductive epoxy adhesive.

[0033] Take 0.5ml adhesive to test its viscosity: the viscosity is 12000Cp at 25°C; the thixotropic index is 5.5; the glue can be cured in 3 minutes at 150°C; the 2*2mm chip, the Ag / Cu frame can withstand a horizontal shear force of more than 15kg at 25°C; curing The resin overflow measurement before is 0, and the resin overflow is 0 after curing; the thickness of the adhesive layer is 15-20 microns, and the maximum height difference of the four corn...

Embodiment 3

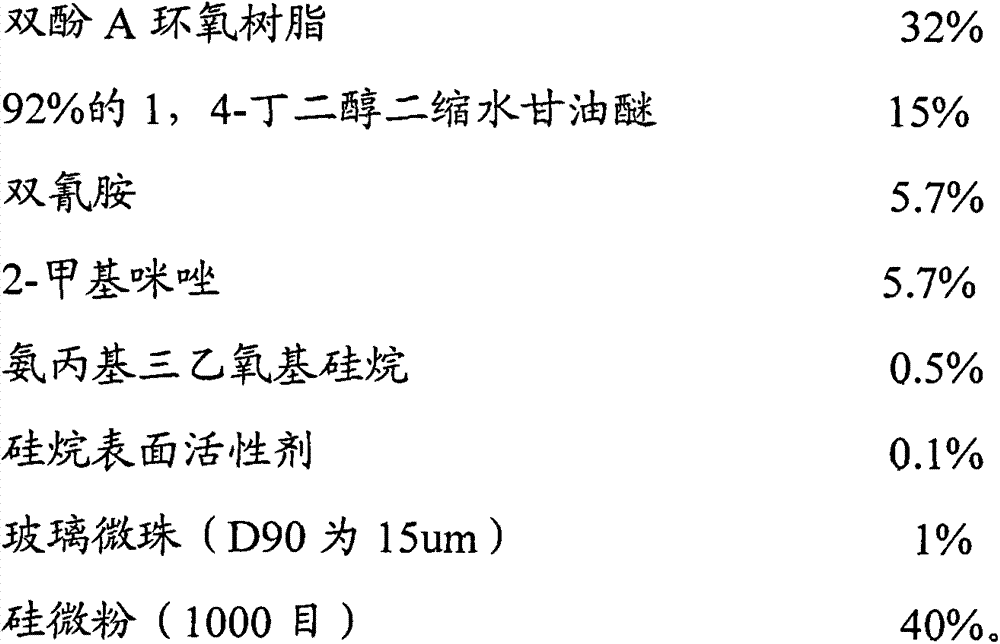

[0035] The formula is:

[0036]

[0037]

[0038] Preparation method: Bisphenol A epoxy resin, novolac epoxy resin, 92% 1,4-butanediol diglycidyl ether, polyether amine, 2-ethyl-4-methylimidazole, bis( Mix triethoxysilylpropyl) polysulfide and fluorine-containing surfactant evenly, mix twice through a three-roll machine, then add fumed silica, stir evenly, mix twice through a three-roll machine, and then add The glass beads were stirred for half an hour, and vacuum defoamed for 30 minutes to obtain the non-conductive epoxy resin adhesive of the present invention.

[0039]Take 0.5ml adhesive to test its viscosity: the viscosity is 11000Cp at 25°C; the thixotropic index is 6.0; the glue can be cured in 3 minutes at 150°C; the 2*2mm chip, the Ag / Cu frame can withstand a horizontal shear force of more than 20kg at 25°C; curing The resin overflow measurement before is 0, and the resin overflow after curing is 0; the thickness of the adhesive layer is 20-25 microns, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com