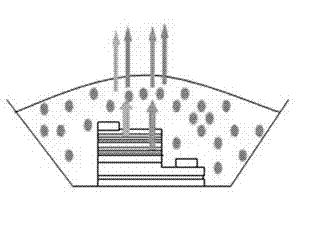

GaN-base double-blue-light wavelength luminescent device and preparation method thereof

A blue light and wavelength technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of shortening the service life of LEDs, difficulty in InGaN films, uneven luminous intensity, etc., to improve the lumen efficiency and the uniformity of electron hole concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions are given to enable those skilled in the art to make and use the invention, and are provided in the context of specific applications and needs. Various modifications to the disclosed embodiments will be readily apparent to those skilled in the art, and the general principles defined herein may be applied to other embodiments and applications without departing from the spirit and scope of the invention. The invention is therefore not limited to the embodiments shown, but is to be accorded the broadest scope consistent with the claims.

[0033] The substrate material of the existing GaN-based LED epitaxial wafer structure can be sapphire, SiC, Si, GaN, etc. The low-temperature buffer layer can be a low-temperature GaN layer or a low-temperature AlN layer, etc. When GaN is used as the substrate, the low-temperature buffer layer and the undoped GaN layer may not be grown. Multiple quantum well structures include InGaN / GaN structure, InGaN / AlGaN st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com