Filling method of hydrocarbon oil catalytic cracking additive

A catalytic cracking and additive technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of large amount of additives, increased emulsification equipment, unstable operation of the device, etc. effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

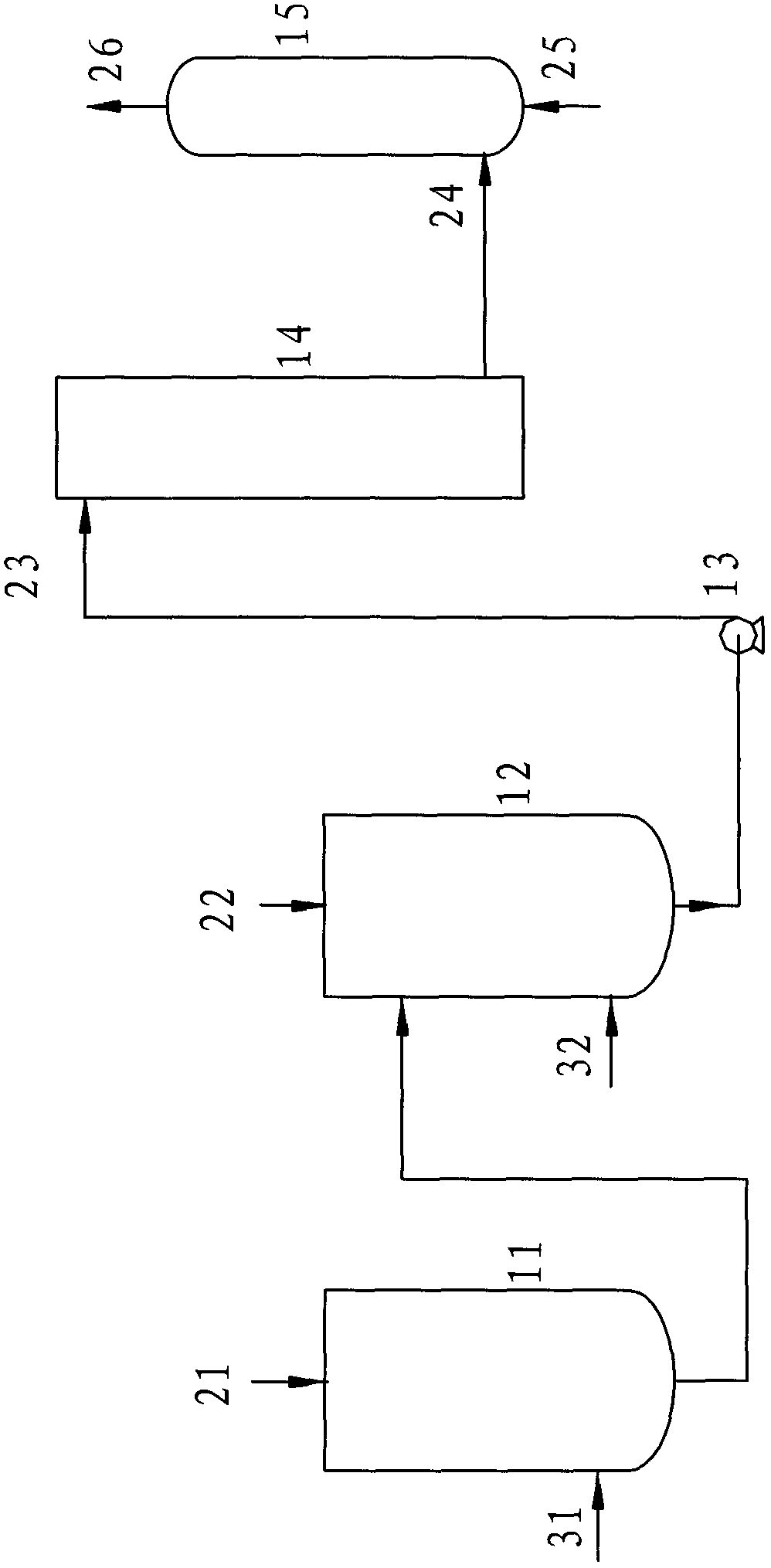

Image

Examples

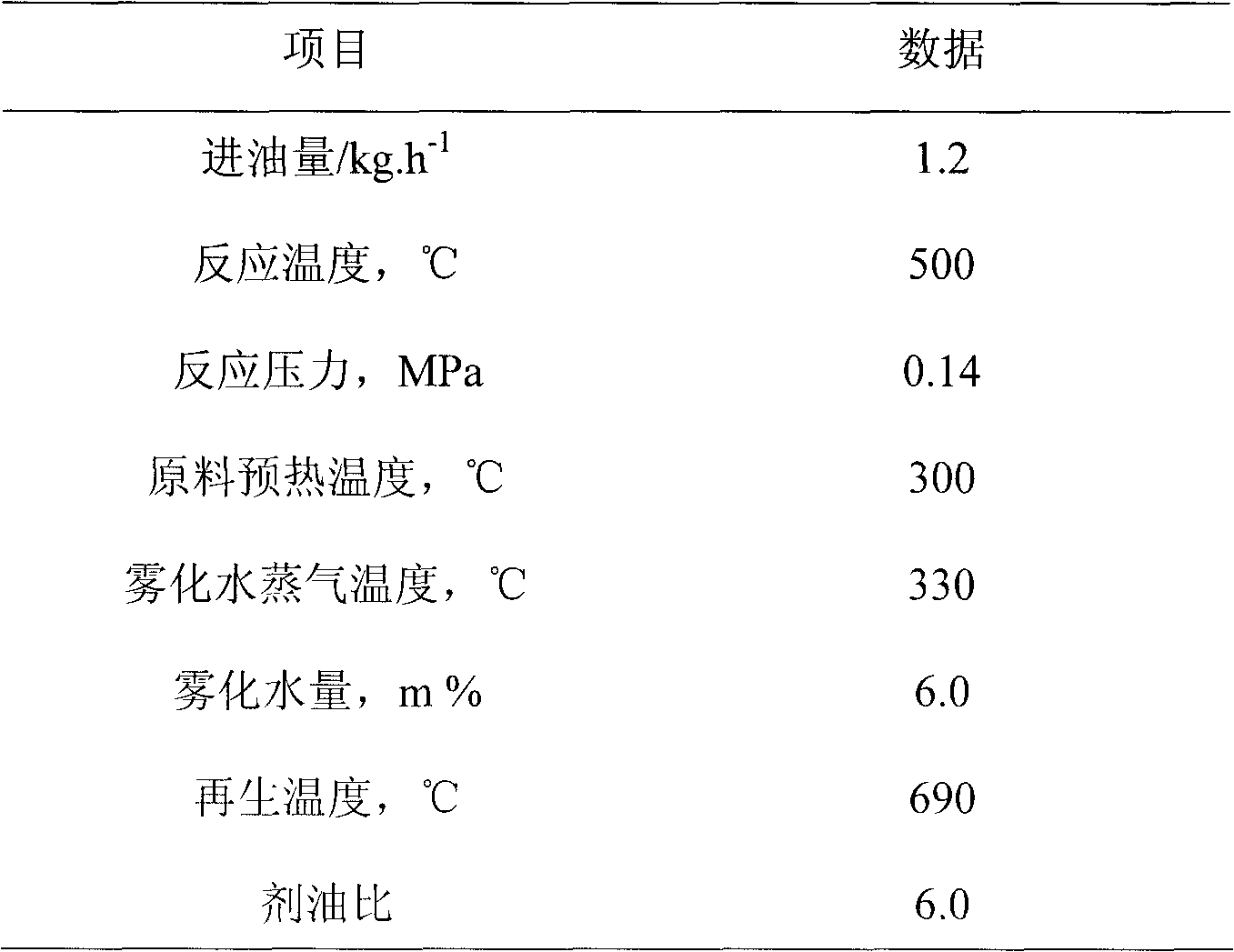

Embodiment 1

[0023] The same as Comparative Implementation 1, the difference is that the additive deionized water is mixed, after the steam generator reaches the atomized steam temperature of the raw material, it enters the nozzle mixing chamber of the riser to mix with the raw material oil, and the mixture is sprayed out through the nozzle for cracking reaction. Table 4 has listed test data, adopts the present invention, and raw material conversion rate improves 3.58 percentage points, and liquefied gas yield improves 0.84 percentage points, and light oil yield improves 3.50 percentage points, and total liquid yield improves 4.34 percentage points, and coke yield reduces 1.04 percentage points, the dry gas production rate did not change much.

Embodiment 2

[0025] Same as Example 1, except that the amount of additive was adjusted to 70 μg / g, the results are listed in Table 4. After changing the amount of additive, the conversion rate of raw materials increased by 3.97 percentage points, the yield of liquefied gas increased by 1.17 percentage points, and the yield of light oil The total liquid yield increased by 4.11 percentage points, the total liquid yield increased by 5.28 percentage points, the coke yield decreased by 1.18 percentage points, and the dry gas yield increased by 0.12 percentage points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com