Reinforced root resistant waterproof roll and production process thereof

A waterproofing membrane, root puncture-resistant technology, applied in the field of waterproofing, can solve the problems of building body damage, failure, penetration of plant root tips, etc., and achieve the effects of long service life, strong impact resistance, and good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

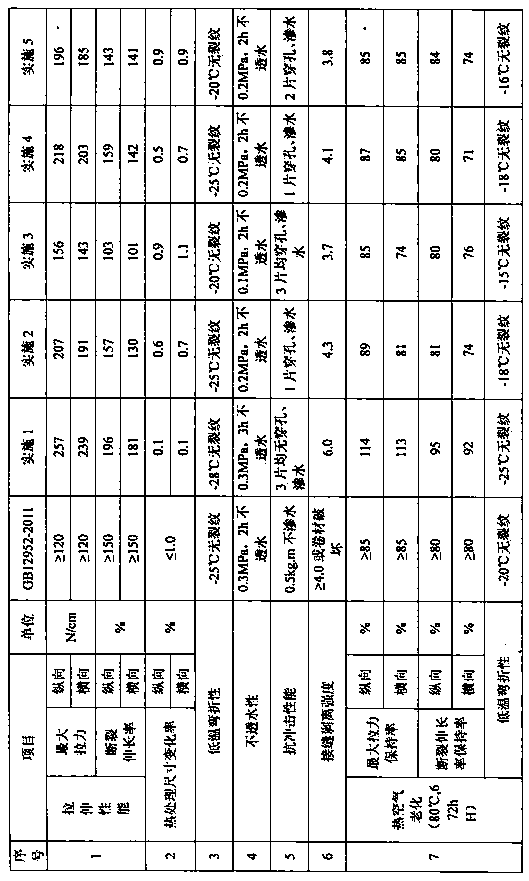

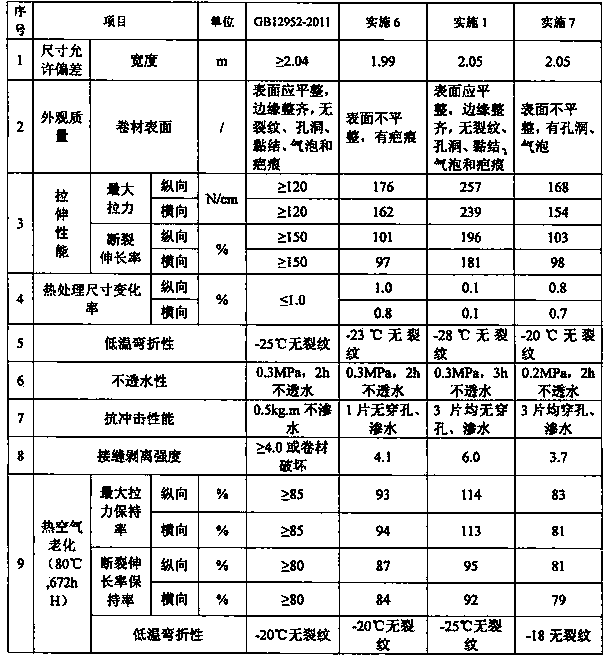

Embodiment 1

[0024] An enhanced root puncture-resistant waterproof membrane, calculated in parts by weight, including 3 parts of flame retardant FR-301, 16 parts of migration-resistant plasticizer, 70 parts of polyvinyl chloride resin, and 5 parts of epoxy soybean oil , 3 parts of di-salt lead phosphite, 3 parts of tri-salt lead phosphite, 4.5 parts of E-881 modified vinyl acetate copolymer resin and 3 parts of epoxy resin, including filament polyester cloth and root-blocking copper base, The content of the filament polyester cloth is 800g / m 2 .

[0025] According to the proportioning relationship calculated according to the weight parts of the above-mentioned material components, the steps of the production process of the enhanced root-resistant puncture-resistant waterproof membrane according to the present invention are as follows:

[0026] Step 1: Calculated by weight, 3 parts of flame retardant, 16 parts of anti-migration plasticizer, 70 parts of polyvinyl chloride resin, 5 parts of ...

Embodiment 2

[0035] On the basis of Example 1, the number of parts of the anti-migration plasticizer in the waterproof membrane is changed, and on the premise that other parameters remain unchanged, the production process described in Example 1 is still used to produce the waterproof membrane. Parts calculation, the migration-resistant plasticizer in the homogeneous layer 4 described in Example 2 is 15 parts.

Embodiment 3

[0037] On the basis of Example 1, the number of parts of the anti-migration plasticizer in the waterproof membrane is changed, and on the premise that other parameters remain unchanged, the production process described in Example 1 is still used to produce the waterproof membrane. Parts calculation, the anti-migration plasticizer in the homogeneous layer 4 described in embodiment 3 is 10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com