A kind of carbon nanotube doped basic anion exchange composite membrane and its preparation method and application

A basic anion, carbon nanotube technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of complex preparation process, poor membrane stability, unfavorable environmental protection, etc., and achieves simple preparation method, film-forming property Good, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

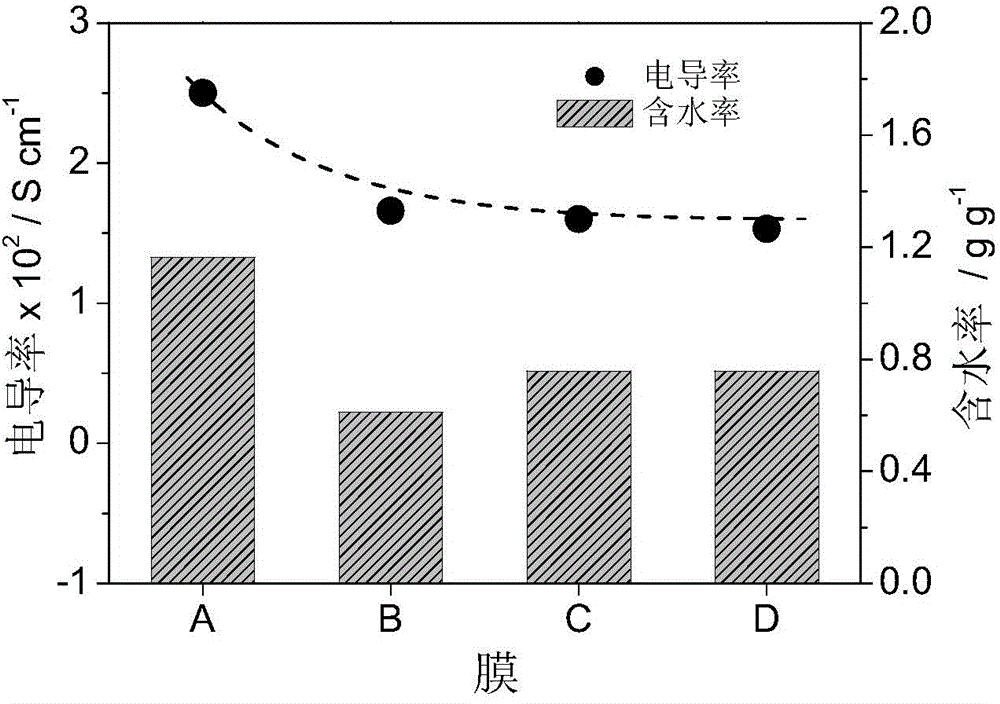

Embodiment 1

[0029] Dissolve 30g of PVA powder in 300ml of deionized water, heat and stir at 90°C until a transparent and homogeneous solution is prepared to obtain a 10% PVA stock solution; prepare a uniform PDDA solution according to the mass ratio of PVA to PDDA = 1:0.5; press PVA and PDDA 1wt% of the total amount was stirred and ultrasonicated respectively to prepare uniform mixed solutions of unmodified multi-walled carbon nanotubes MWCNTs, hydroxyl-modified multi-walled carbon nanotubes MWCNTs-OH, and carboxyl-modified multi-walled carbon nanotubes MWCNTs-COOH; the above solutions Mix and stir for 24 hours to obtain a uniform mixed solution, cast the mixed solution into a plastic disc, and dry naturally to form a film. The film was peeled off and placed in an oven for heat treatment at 150°C for 1 hour, and then immersed in 10% (volume percent) glutaraldehyde (GA, 25wt.%) acetone (≥99.5wt.%) containing a small amount (2% mass percent) of HCl. %) solution and stirred for 1 h, the memb...

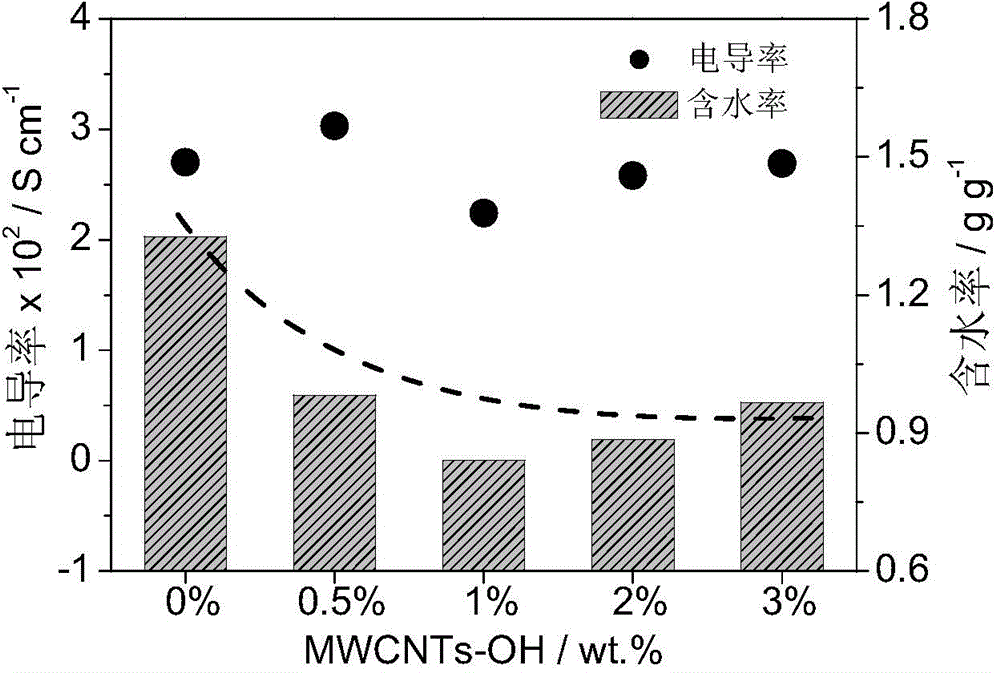

Embodiment 2

[0032]Dissolve 30g of PVA powder in 300ml of deionized water, heat and stir at 90°C until a transparent and homogeneous solution is prepared to obtain a 10% PVA stock solution; prepare a uniform PDDA solution according to the mass ratio of PVA to PDDA = 1:0.5; press PVA and PDDA 0wt.%, 0.5wt.%, 1wt.%, 2wt.%, 3wt.% of the total amount were stirred separately and ultrasonically prepared to prepare uniform mixed solutions with different hydroxyl-modified multi-walled carbon nanotubes MWCNTs-OH doping content; mix the above The solution was cast into a plastic disc and dried naturally to form a film. Peel off the film and place it in an oven for heat treatment at 150°C for 1 hour, then soak in 5% (volume percent) glutaraldehyde (GA, 25wt.%) acetone (≥99.5wt.%) containing a small amount of HCl (0.2%, mass percent) .%) solution and stirred for 1 h, the membrane was taken out, immersed in deionized water to fully wash, and then stored in deionized water to obtain a modified quaternar...

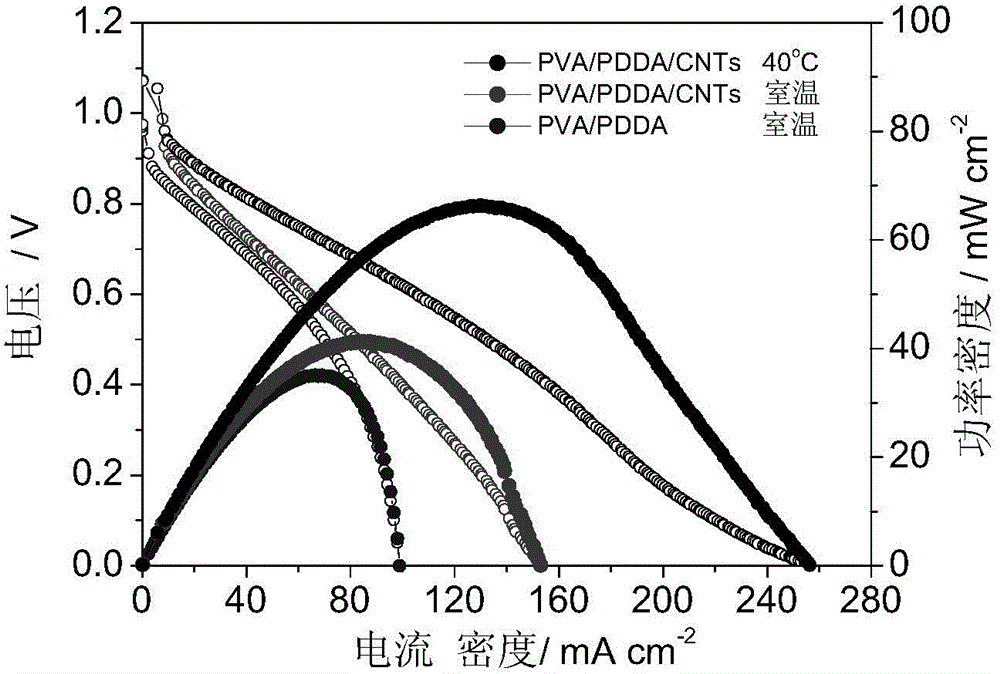

Embodiment 3

[0035] The prepared PVA / 50%PDDA / MWCNTs-OH - The power generation performance of composite membrane prepared membrane electrode (MEA) was carried out on GE / FC1-100 fuel cell activation system. Both cathode and anode use Johnson Matthey's commercial 40% Pt / C catalyst with a Pt loading of 0.5 mg / cm 2 . The hot pressing condition of membrane electrode MEA is 6MPa-60℃-6min, and the effective active area of membrane electrode MEA is 4cm 2 . The anode fuel is hydrogen with a flow rate of 100mL / min; the cathode is oxygen with a flow rate of 70mL / min. Power generation tests were performed at room temperature and 40°C respectively, and the results are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com