Non-aqueous electrolyte for lithium ion battery, and application thereof

A non-aqueous electrolyte, lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

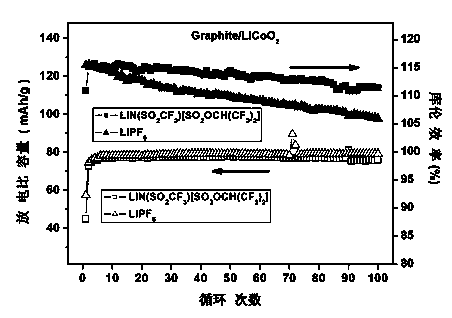

Embodiment 1

[0068] (1) Production of positive electrode

[0069] LiCoO 2 Powder, carbon black (particle size 1000nm), polyvinylidene fluoride (PVDF) and N,N-dimethylpyrrolidone (NMP) are mixed to make a uniform slurry, and the slurry is evenly coated on an aluminum foil (15 μm) current collector on, then dried and rolled to obtain LiCoO 2 Cathode material. Bake at 120°C for 12 hours, and in the dried pole piece, LiCoO 2 It accounts for 94% of the total coating, binder accounts for 4%, and carbon black accounts for 2%. Then the obtained pole piece was cut into a disc with a diameter of 12 mm as the positive pole.

[0070] (2) Production of negative electrode

[0071] Artificial graphite, polyvinylidene fluoride (PVDF) and N,N-dimethylpyrrolidone (NMP) were mixed to make a uniform slurry, and the slurry was uniformly coated on a copper foil (15 μm) current collector, and then dried , rolled to obtain the carbon negative electrode material. Bake at 120° C. for 12 hours. In the dried p...

Embodiment 2

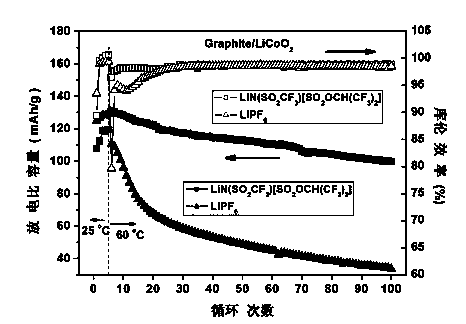

[0080]The same non-aqueous electrolyte as in Example 1 was used to assemble the same battery as in Example 1, and the assembled battery was tested for high-temperature cycle performance. Test conditions: Before the high-temperature test, the assembled battery is cycled at 25°C for 5 weeks, and then transferred to a constant temperature test box at 60°C for high-temperature cycle test. The cut-off voltage is 4.2-2.75V. The charge rate is 0.5C, and the discharge rate is 0.2C. The test data of this embodiment is shown in Table 1. The cycle specific capacity and Coulombic efficiency of the battery are as follows: figure 2 shown.

Embodiment 3

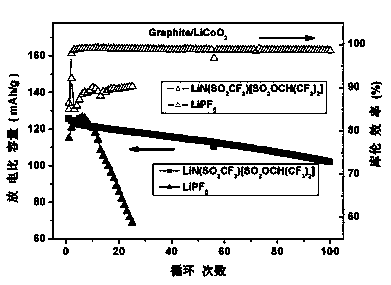

[0084] The same non-aqueous electrolyte as in Example 1 was used to assemble the same battery as in Example 1, and the assembled battery was tested for high-temperature cycle performance. Test conditions: The assembled battery is directly subjected to a high-temperature formation test in a constant temperature test box at 60°C, and the cut-off voltage is 4.2-2.75V. The charge rate is 0.5C, and the discharge rate is 0.2C. The test data of this embodiment is shown in Table 1. The cycle specific capacity and Coulombic efficiency of the battery are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com