Novel double-component developer

A two-component developer and toner technology, which is applied in the direction of developer, electrography, optics, etc., can solve the problem of reduced carrying force of carrier particles, and achieve low environmental dependence, electrical and magnetic properties Good, the effect of solving the problem of carrier dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

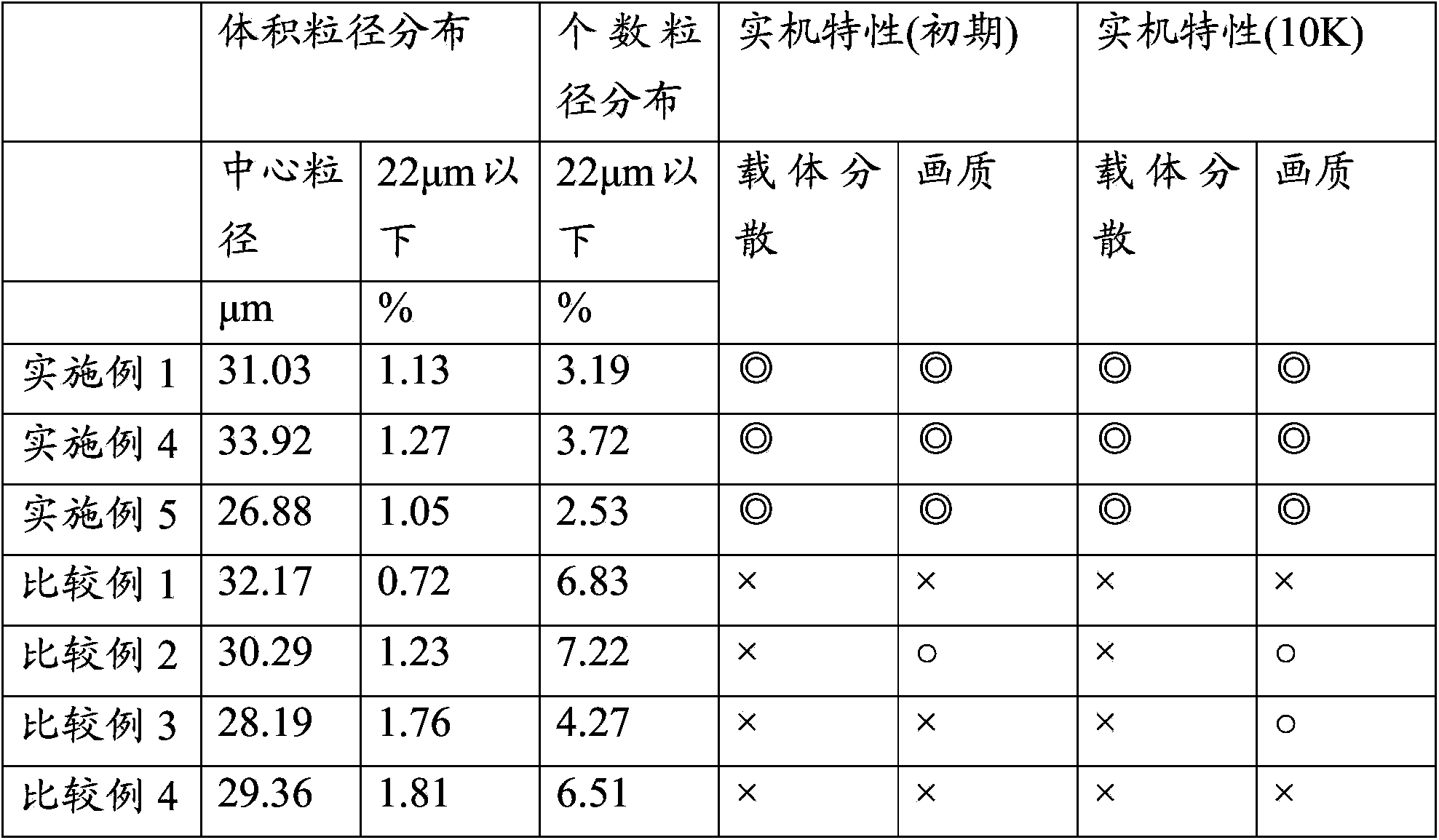

Examples

preparation example Construction

[0029] The preparation method of the carrier core material is specifically:

[0030] The first step is to select iron-containing raw materials and magnesium-containing raw materials, and mix them in an appropriate proportion according to the proportion of the final product. The magnesium-containing raw materials are preferably MgO, and the iron-containing raw materials are optionally selected as Fe 2 o 3 ;

[0031] In the second step, add reducing agent and water to the raw materials mixed in the first step, mix and stir to make slurry, and make slurry raw materials. The reducing agent can be carbon powder or polycarboxylic acid organic matter, polyacrylic acid organic matter , maleic acid, acetic acid, polyvinyl alcohol and mixtures thereof, the solid component concentration accounts for more than 50% of the entire mixed slurry concentration;

[0032] The third step is to granulate the raw materials after the slurrying in the second step by means of spray drying, the spray ...

Embodiment 1

[0059] Example 1 Preparation of toner

[0060] Add 7.5 parts by weight of colorant carbon black, 2.0 parts by weight of polyethylene and 1.0 parts by weight of charge control agent to 100 parts by weight of the adhesive resin polystyrene, fully mix with a high-speed mixer, and melt the obtained mixture with a twin-screw kneader Knead. The resulting kneaded mixture was pulverized by a jet mill and then classified to obtain toner base particles having a volume average particle diameter of 7.0 μm. A toner was obtained by adding 1.2 parts by weight of silica fine particles as an external additive to 100 parts by weight of the toner base particles.

Embodiment 2

[0061] Example 2 Preparation of Carrier Core Material 1

[0062] Disperse 13.7kg Fe in 7.5kg water 2 o 3 (average particle diameter: 1 μm), 6.5 kg of MgO (average particle diameter: 1 μm), 135 g of ammonium polycarboxylate dispersant was added as a dispersant, and 68 g of carbon black was added as a reducing agent to prepare a mixture. When the solid content concentration at this time was measured, it was 75 weight%. The mixture was pulverized by a wet ball mill (medium diameter: 2 mm) to obtain a mixed slurry. The slurry was sprayed in hot air at about 130°C by a spray dryer to obtain dry granulated powder. And, at this time, the granulated powder outside the target particle size distribution was removed by a sieve. The granulated powder was put into an electric furnace and baked at 1130° C. for 3 hours. At this time, the atmosphere was adjusted so that the oxygen concentration in the electric furnace was 0.8% into the electric furnace. The obtained calcined product was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

| Magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com