Cu-fe-ag-re magnetic copper alloy for energy-saving motor rotor and preparation method thereof

A cu-fe-ag-re, motor rotor technology, applied in the field of Cu-Fe-Ag-RE magnetic copper alloy for new energy-saving motor rotor and its preparation, can solve the problems of large starting current and low starting torque, etc. , to reduce the starting current, improve the starting torque, and improve the efficiency of energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

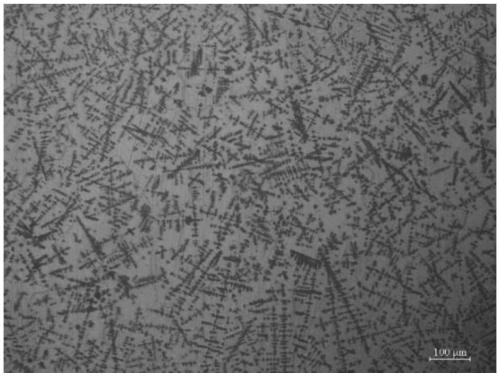

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of preparation method of Cu-Fe-Ag-RE magnetic copper alloy for new energy-saving motor rotor, comprises the following steps:

[0034] Step 1: Ingredients

[0035] According to the material composition requirements of Fe: 5%, Ag: 0.15%, RE: 0.08%, and Cu: the balance, select and weigh the corresponding raw materials for the ratio of each alloy element; among them, Cu is added by electrolytic copper plate, and Fe is added by industrial Pure iron is added, Ag is added by chemical silver particles, and RE is added by La-Ce alloy;

[0036] Step 2: Smelting

[0037] Use non-vacuum intermediate frequency induction furnace for smelting, first add industrial pure iron, after the industrial pure iron melts, add electrolytic copper and keep it at 1300 ° C for 30 minutes, use quartz glass tube to stir evenly, then add silver particles and RE; after degassing and refining , and finally use charcoal to cover and keep warm for 30 minutes to prepare for casting; ...

Embodiment 2

[0041] Example 2: The difference from Example 1 is that the Cu-Fe-Ag-RE ingot obtained in step 3 is heated to 900°C for hot extrusion, and then the hot-extruded profile is cold drawn, and the cold deformation 50%; then carry out aging treatment, the aging treatment temperature is 400°C, and the holding time is 3 hours.

[0042] The material prepared by the above method has a conductivity of 65% IACS, a strength of 685MPa, and a certain magnetic permeability.

Embodiment 3

[0043] Embodiment 3: A kind of preparation method of Cu-Fe-Ag-RE magnetic copper alloy for new energy-saving motor rotor, comprises the following steps:

[0044] Step 1: Ingredients

[0045] According to the material composition requirements of Fe: 10%, Ag: 0.25%, RE: 0.08%, and Cu: the balance, select and weigh the corresponding raw materials for the ratio of each alloy element; among them, Cu is added by electrolytic copper plate, and Fe is added by industrial Pure iron is added, Ag is added by chemical silver particles, and RE is added by La-Ce alloy;

[0046] Step 2: Smelting

[0047] Use non-vacuum intermediate frequency induction furnace for smelting, first add industrial pure iron, after the industrial pure iron melts, add electrolytic copper and keep it at 1300 ° C for 30 minutes, use quartz glass tube to stir evenly, then add silver particles and RE; after degassing and refining , and finally use charcoal to cover and keep warm for 30 minutes to prepare for casting;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com