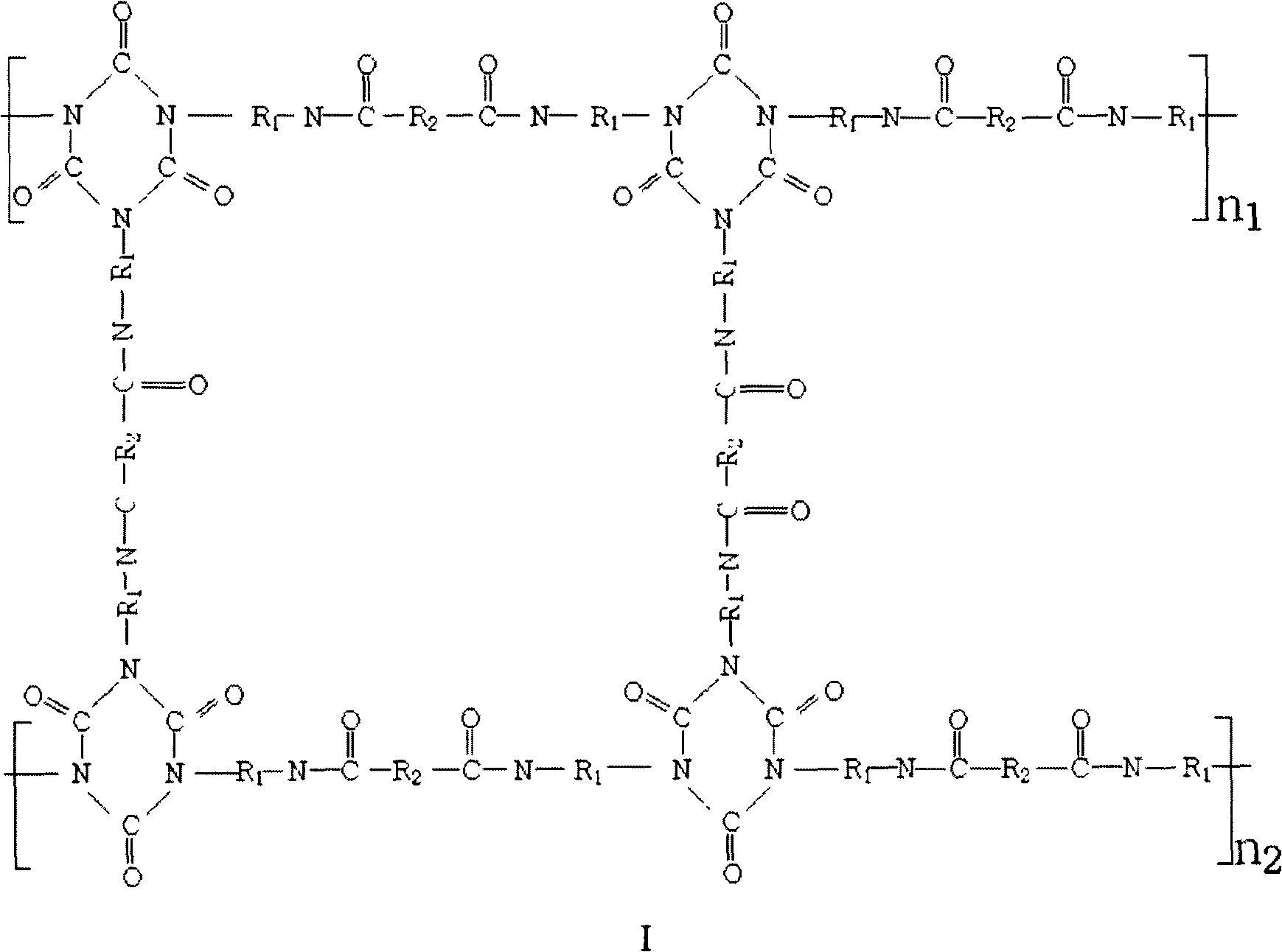

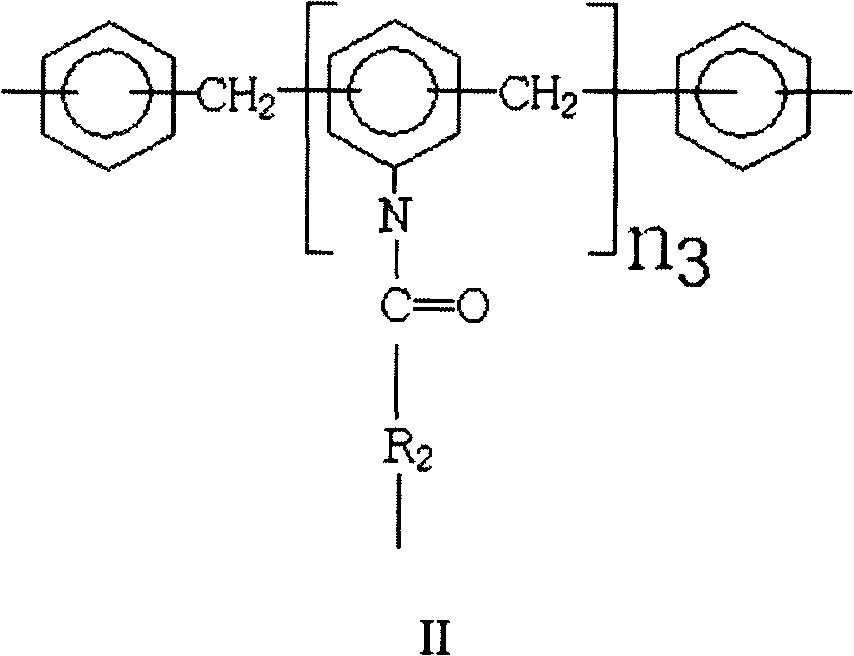

Preparation and application of polyisocyanurate modified phenol formaldehyde foam plastic

A technology of polyisocyanurate and phenolic foam, which is applied in the field of polyisocyanurate modified phenolic foam, can solve the problems of low density and difficult realization of spray molding process, great influence on strength and thermal conductivity, and poor Suitable for problems such as spray molding process, to achieve fast curing time, improve mechanical properties, and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

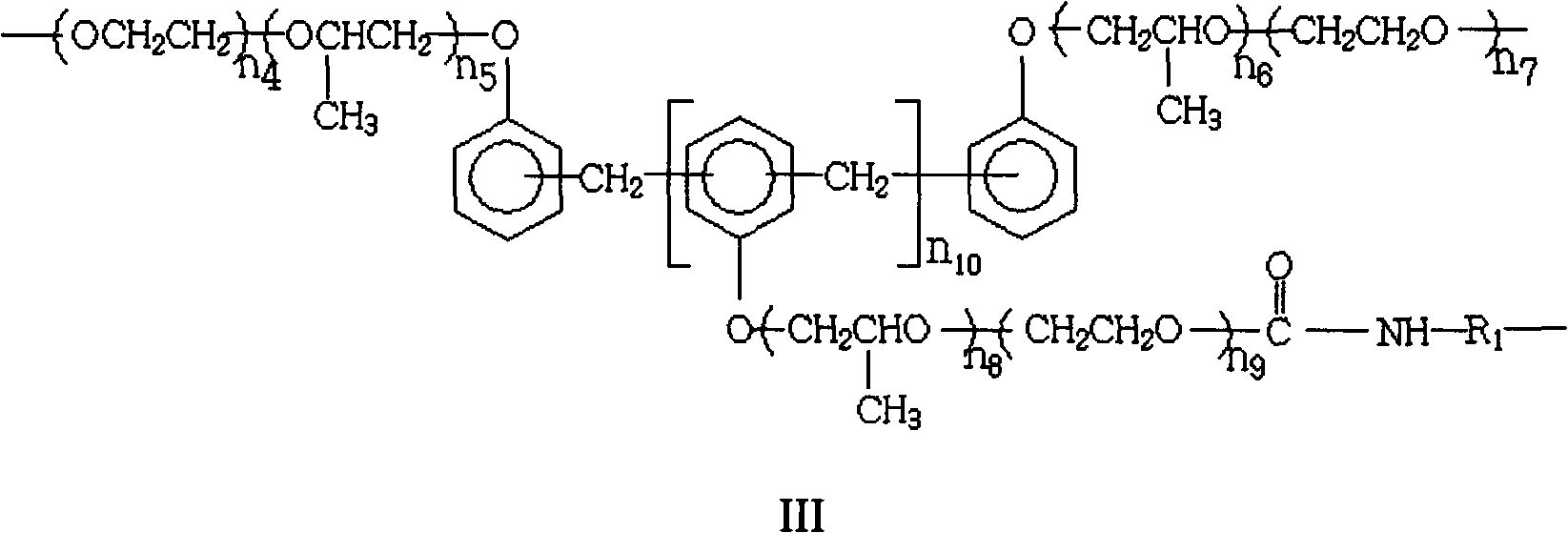

[0073] One of the synthesis of embodiment 1-F-polyol copolymer polyol

[0074] Preheat 100 parts by weight of phenol to 40-60°C to melt, add 44 parts by weight of 37wt% formaldehyde aqueous solution and 2 parts by weight of 50wt% aqueous oxalic acid solution, and react for 3 hours at a temperature of 60-75°C. After the reaction is over, adjust the pH value to 7-7.5 with disodium hydrogen phosphate solution, then add 20 parts by weight of glycerin and 0.3 parts by weight of KOH, and vacuumize at 60-80 ° C for 4 hours to dehydrate. The vacuum pressure is -0.09MPa to -0.1 MPa. After the dehydration is completed, 145 parts by weight of propylene oxide is added to keep the reaction temperature at 90-120° C. and the reaction pressure at 0.3-0.6 MPa. When the pressure drops to 0MPa, it means that the phenolic condensation reaction is complete. Then add 110 parts by weight of ethylene oxide, keep the reaction temperature at 90-120° C., and the reaction pressure at 0.3-0.6 MPa. When...

Embodiment 2

[0075] Synthetic two of embodiment 2-F-polyol copolymer polyol

[0076] Preheat 100 parts by weight of phenol to 40-60°C to melt, add 182 parts by weight of 37% by weight formaldehyde solution and 4 parts by weight of CaO, and react for 4 hours at a temperature of 70-90°C. After the reaction, adjust the pH value to 7-7.5 with phosphoric acid, then add 60 parts by weight of glycerin and 1 part by weight of KOH, and vacuumize at 60-80° C. for 4 hours to dehydrate at a vacuum pressure of -0.09 MPa to -0.1 MPa. After the dehydration is completed, 226 parts by weight of propylene oxide are added to keep the reaction temperature at 90-120° C. and the reaction pressure at 0.3-0.6 MPa. When the pressure drops to 0MPa, it means that the phenolic condensation reaction is complete. Then add 150 parts by weight of ethylene oxide, keep the reaction temperature at 90-120° C., and the reaction pressure at 0.3-0.6 MPa. When the pressure drops to 0MPa, it means that the epoxy ring-opening po...

Embodiment 3

[0077] The preparation of embodiment 3-component A

[0078] According to the formula in Table 1, each component can be stirred evenly at room temperature.

[0079] Table 1. Composition of Part A

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com