Infrared gas sensor for detecting a variety of gases

A gas sensor and sensor technology, applied in semiconductor devices, instruments, electrical components, etc., can solve the problems of not realizing simultaneous detection of multiple gases, increasing complexity and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

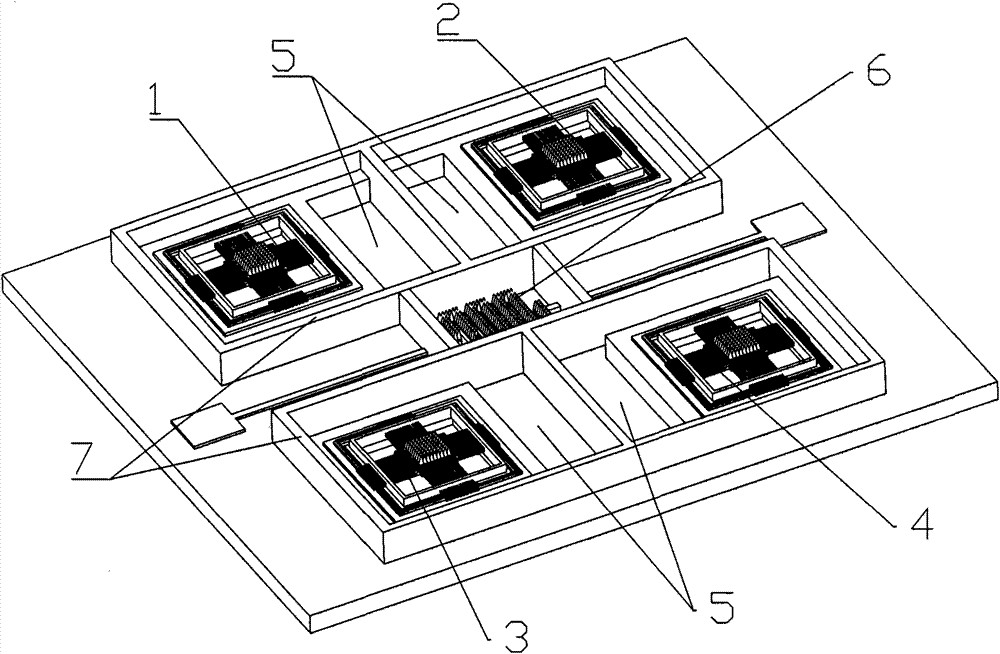

[0103] refer to figure 1 ,exist figure 1 The shown infrared gas sensor for multi-gas detection includes four sensitive elements, which are respectively: the first sensitive element 1, the second sensitive element 2, the third sensitive element 3 and the reference sensitive element 4, and the four sensitive elements are all Distributed on the circle centered on the nano-surface modified infrared light source 6, wherein two thermal insulation channels 5 are set between the first sensitive element 1 and the second sensitive element 2, and the third sensitive element 3 and the reference sensitive element 4 Two same heat-insulating channels 5 are also arranged between them; the four sensitive elements and the periphery of the nanometer surface-modified infrared light source 6 are all thermally isolated from each other by a thermal isolation wall 7 to reduce the influence of thermal crosstalk.

[0104]Using MEMS technology, four gas infrared sensors and MEMS infrared light sources ...

Embodiment 2

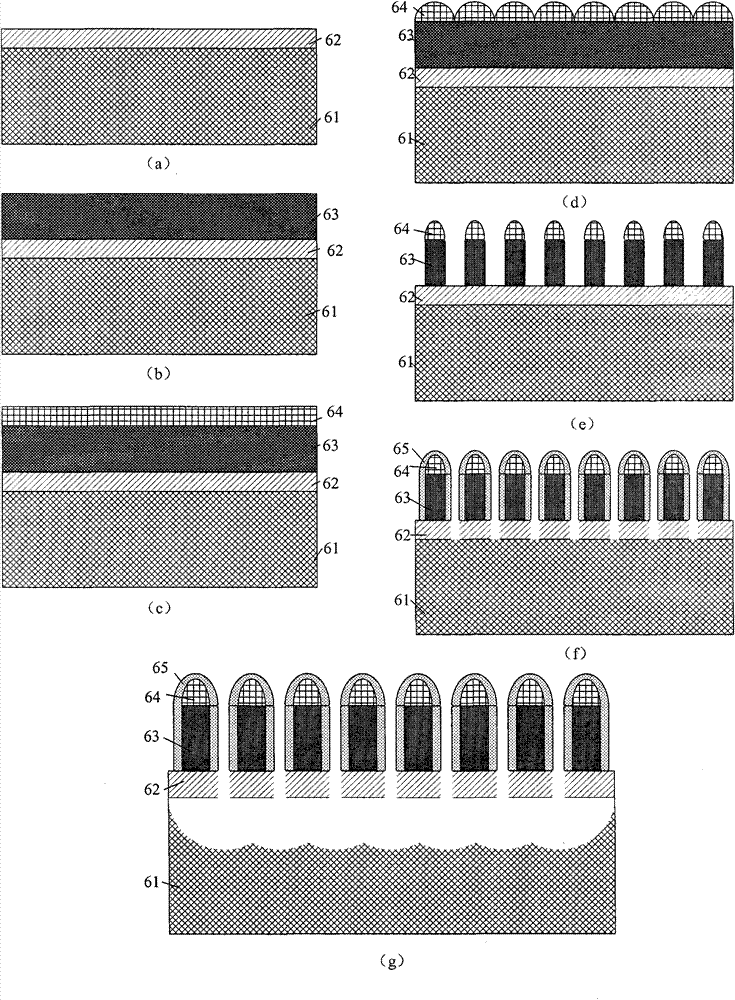

[0106] The present embodiment provides a nano surface modified infrared light source 6, as a specific example, refer to figure 2 In steps (a)-(g), the preparation process of the nano-surface modified infrared light source 6 of the present invention is described in detail as follows:

[0107] (a), growing silicon nitride 62 on a single crystal silicon substrate 61, experimental conditions; temperature 780°C, 330mTorr, SiH 2 Cl 2 ;24 sccm, NH 3 : 90 sccm;

[0108] (b) Deposition of amorphous silicon 63: the temperature is 270°C, the gas flow rate and ratio are SIH 4 : 24% NH 3 : 55%N 2 :5.2%RF:170;

[0109] (c), Al sputtering and annealing: magnetron sputtering Al, conditions: air pressure 10mTorr, after feeding Ar to meet the air pressure conditions, set RF to 8400W, and then perform annealing treatment at 450°C for 90 minutes;

[0110] (d) Wet etching of the Al film: using a conventional Al etching solution, Al-Si compound particles remain on the surface of the sample ...

Embodiment 3

[0122] 1) Infrared gas sensor concentration signal processing method

[0123] There are many gas detection methods based on the principle of infrared optics, among which the dual-wavelength detection method is more commonly used. This method can play the role of reference wavelength environment compensation, thereby effectively improving the anti-interference and stability of the system. There are also many methods for calculating gas concentration based on optical principles. At present, it is mainly determined which method is used to calculate the gas concentration according to the accuracy requirements. This embodiment mainly describes the linear interpolation-data table look-up calculation method used in the research process. This method is relatively simple, and its processing results meet the application requirements of most early warning and alarm occasions, such as coal mine gas alarms. The accuracy of this method mainly depends on the pre-calibrated data table. The mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com