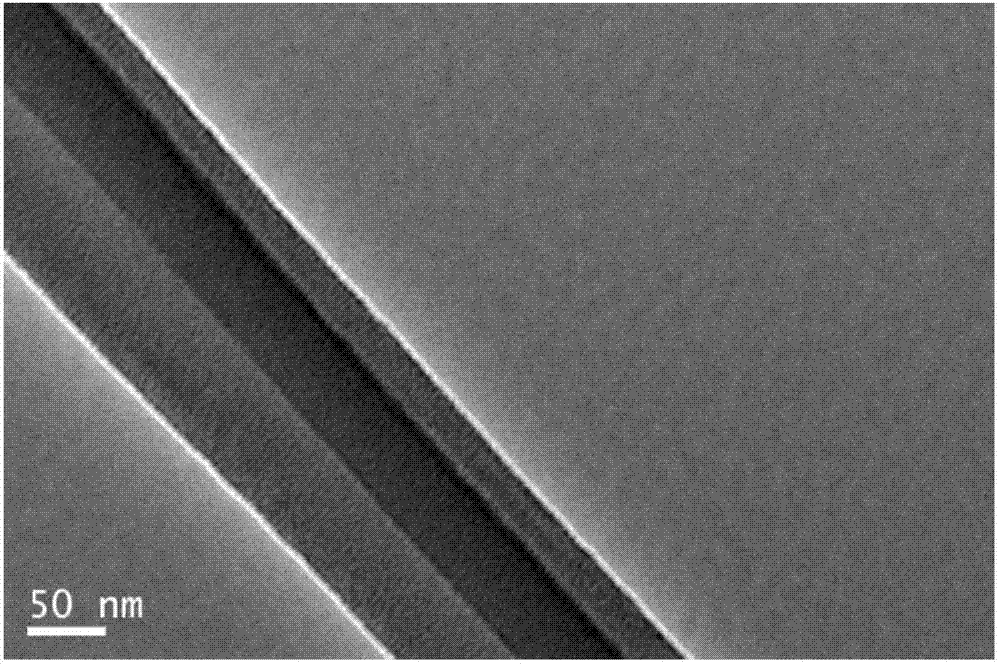

Migratory phase separation method for preparing core-shell structure nanofibers

A technology of core-shell structure and nanofibers, which is applied in fiber treatment, spinning solution preparation, cellulose/protein conjugated artificial filaments, etc. It can solve the problems of high requirements, difficult modification of deep fibers in the membrane, and complicated operations. Problems, to achieve strong corrosion resistance and swelling, low production cost, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

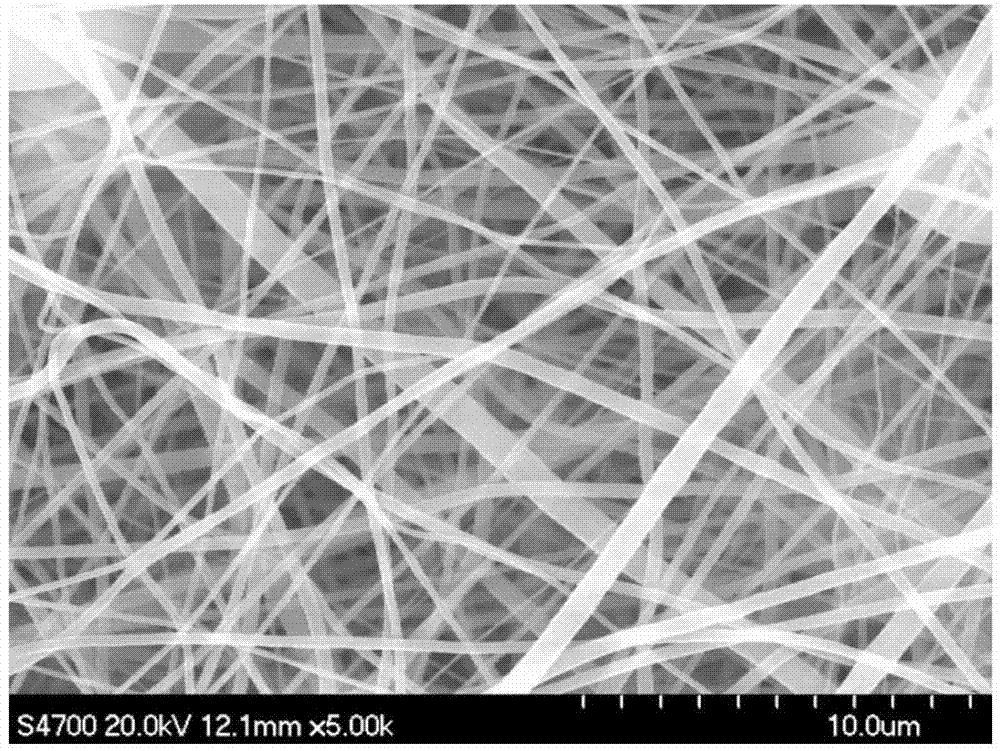

Embodiment 1

[0022] (1) Dissolve PVDF in a mixed solvent with a mass ratio of DMF / acetone of 8:2 at a room temperature of 25°C; place it on a magnetic stirrer and stir and dissolve at a speed of 100 rpm at 75°C until the obtained Transparent solution; be cooled to room temperature, obtain the PVDF solution that weight percent is 18wt%;

[0023] (2) At room temperature 25°C, dissolve PVP in a mixed solvent with a mass ratio of DMF / acetone of 8:2, put it on a magnetic stirrer, and stir and dissolve at 50°C at a speed of 120rpm until the obtained Transparent solution; be cooled to room temperature, obtain the PVP solution that weight percent is 12wt%;

[0024] (3) Mixing of the two electrospinning solutions: Mix the electrospinning solutions in steps (1) and (2) at a weight ratio of 1:3, put them on a magnetic stirrer, and set the temperature at 50°C at 120rpm Stir and mix at a high speed until the solution is evenly mixed; cool to room temperature, and place the solution in an ultrasonic in...

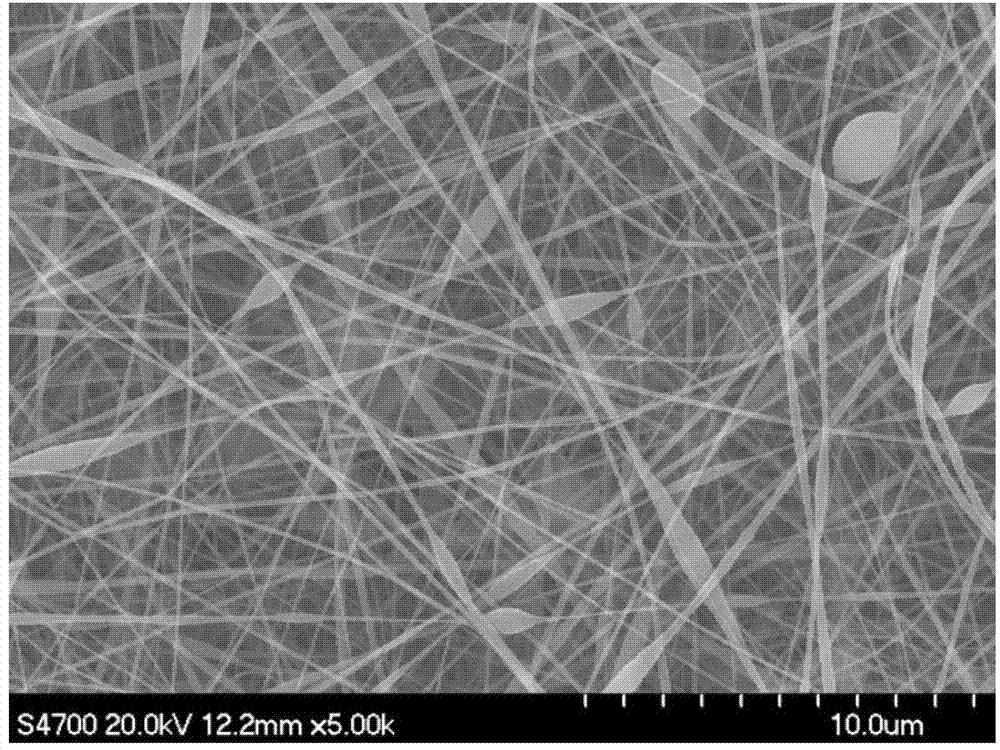

Embodiment 2

[0027] (1) Dissolve PVDF in a mixed solvent with a mass ratio of DMF / acetone of 8:2 at a room temperature of 25°C; place it on a magnetic stirrer and stir and dissolve at a speed of 100 rpm at 75°C until the obtained Transparent solution; be cooled to room temperature, obtain the PVDF solution that weight percent is 18wt%;

[0028] (2) At room temperature 25°C, dissolve PAN in a mixed solvent with a mass ratio of DMF / acetone of 8:2, put it on a magnetic stirrer, and stir and dissolve at 50°C at a speed of 120rpm until the obtained Transparent solution; be cooled to room temperature, obtain the PAN solution that weight percent is 7wt%;

[0029] (3) Mix the electrospinning solutions in steps (1) and (2) at a weight ratio of 1:3, put them on a magnetic stirrer, and stir and mix at a speed of 120rpm at 50°C until the solutions are mixed Uniform; cool to room temperature, put the solution in an ultrasonic instrument for half an hour, so that all the bubbles are precipitated, and f...

Embodiment 3

[0032] (1) Dissolve PVF in a mixed solvent with a mass ratio of DMF / acetone of 8:2 at a room temperature of 25°C; place it on a magnetic stirrer and stir and dissolve at a speed of 100 rpm at 75°C until the obtained Transparent solution; be cooled to room temperature, obtain the PVF solution that weight percent is 20wt%;

[0033] (2) At room temperature 25°C, dissolve PVP in a mixed solvent with a mass ratio of DMF / acetone of 8:2, put it on a magnetic stirrer, and stir and dissolve at 50°C at a speed of 120rpm until the obtained Transparent solution; be cooled to room temperature, obtain the PVP solution that weight percent is 12wt%;

[0034] (3) Mixing of the two electrospinning solutions: Mix the electrospinning solutions in steps (1) and (2) at a weight ratio of 1:3, put them on a magnetic stirrer, and set the temperature at 50°C at 120rpm Stir and mix at a high speed until the solution is evenly mixed; cool to room temperature, and place the solution in an ultrasonic inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com