Modified pure acrylic emulsion and preparation method thereof

A pure acrylic emulsion, modified technology, applied in the direction of coating, etc., can solve the problems of low hardness of coating film, high film forming temperature, low stability of emulsion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

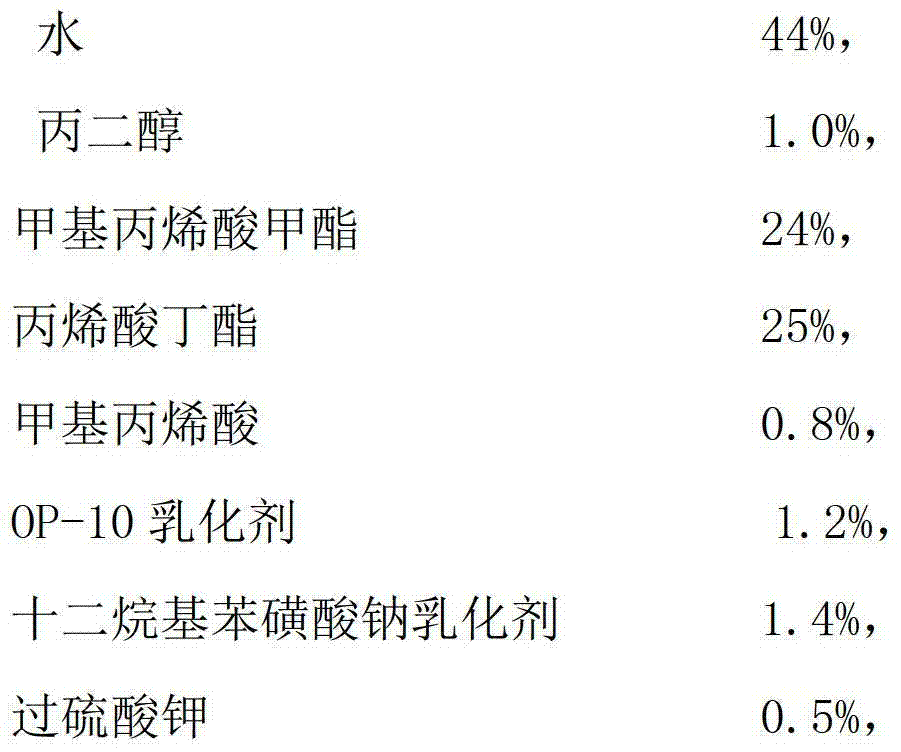

[0014] 1. Nano ZrO 2 The percentage content of each component of the modified pure acrylic emulsion is as follows:

[0015]

[0016]

[0017] 2. Nano ZrO 2 The preparation method of modified pure acrylic emulsion comprises the following steps:

[0018] 1. Nano ZrO 2 Modification treatment: the nano-ZrO 2 , propylene glycol and 1 / 5 of water were added to the container for ultrasonic dispersion for 40 minutes, then KH-570 silane coupling agent and oleic acid mixed modifier were added, and after ultrasonic dispersion was continued for 40 minutes, the dispersion liquid was placed in a reaction vessel and heated in a water bath to 85 ℃, condensed and refluxed for 3.5h, dried and ground after the reaction, and modified nano-ZrO 2 ;

[0019] 2. Methyl methacrylate, butyl acrylate, methacrylic acid and modified nano-ZrO 2 Mix and add to the container, stir with magnetic force for 1.5h, and then disperse with ultrasonic wave for 1.5h to prepare nano-ZrO 2 monomer mixture; ...

Embodiment 2

[0024] 1. Nano ZrO 2 The percentage content of each component of the modified pure acrylic emulsion is as follows:

[0025]

[0026] Two, preparation method is the same as embodiment 1.

[0027] Three, the performance test result of the pure acrylic emulsion of the present embodiment is as follows:

[0028]

Embodiment 3

[0030] 1. Nano ZrO 2 The percentage content of each component of the modified pure acrylic emulsion is as follows:

[0031]

[0032] Two, preparation method is the same as embodiment 1.

[0033] Three, the performance test result of the pure acrylic emulsion of the present embodiment is as follows:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com