Polyketone-grafted modified mesoporous silicon oxide material preparation method

A technology of mesoporous silica and graft modification, which is applied in the field of preparation of mesoporous silica materials, can solve problems such as difficulty in catalyst recovery and reactivation, and achieve the effect of mild polymerization conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

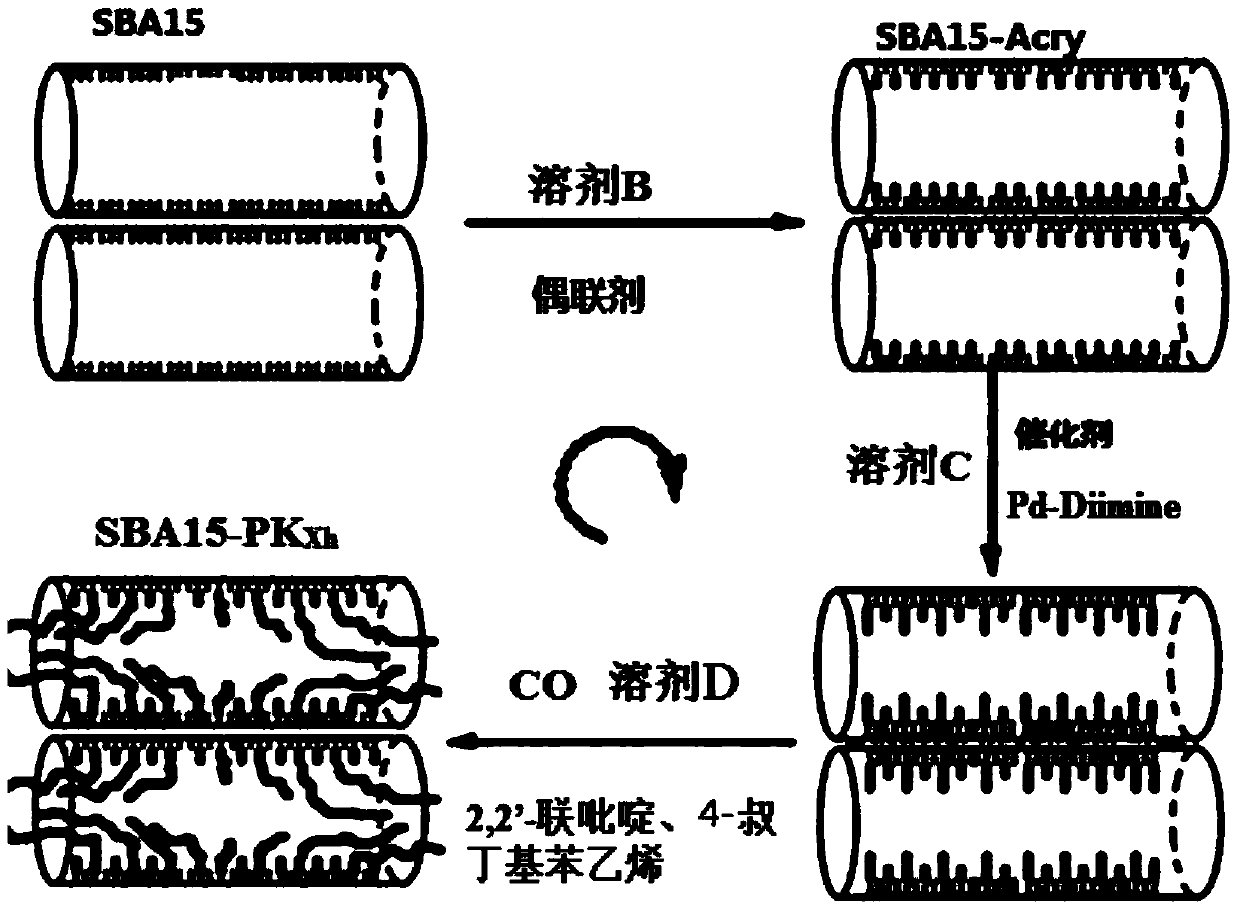

Method used

Image

Examples

Embodiment 1

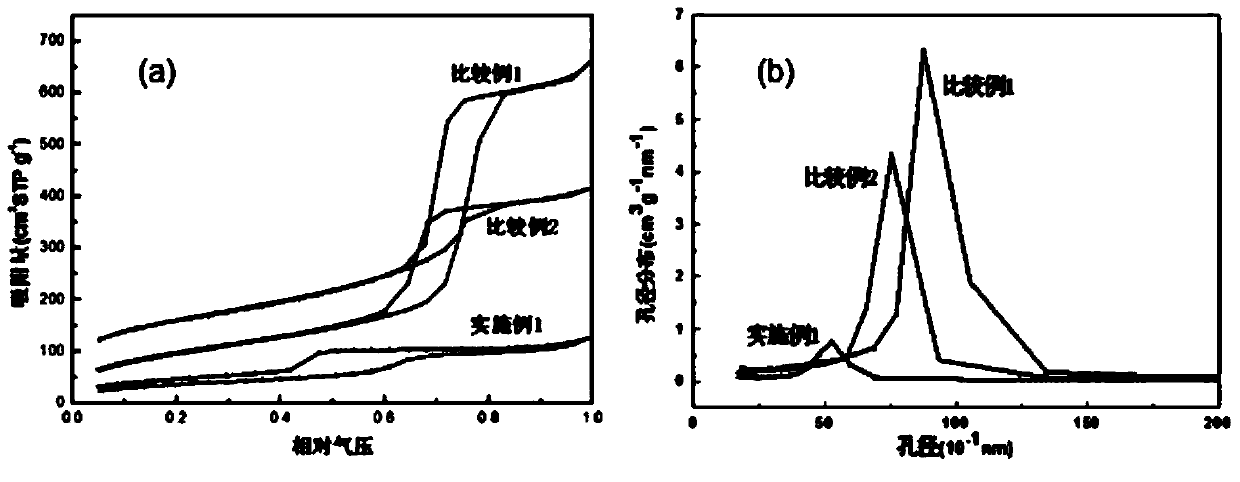

[0050] Embodiment 1, comparative example 1, 2

[0051] (1) The preparation of the sample of Example 1 is carried out according to the following steps:

[0052] Step 1: Weigh mesoporous silica SBA15 (2.4g, pore diameter about 7.2nm, Langmuir specific surface area 556m2 / g), add methanol 40mL, ultrasonically disperse and wash at room temperature 25°C for 1 hour, and then centrifuge ( 9000rpm, 10min), repeat washing three times; add 40mL acetone, ultrasonically disperse at room temperature 25°C for 1 hour, centrifuge, and dry the washed product in a vacuum oven to powder.

[0053] Step 2: Transfer the powdered SBA15 to a 100mL clean schlenk bottle, add a magnetic stirrer, stopper the bottle with a rubber stopper, seal it with parafilm, vacuumize while heating, and continuously vacuum-dry at 250°C for 24 hours. Slowly open the nitrogen gas, cool the SBA15 to room temperature under nitrogen protection, and inject 50 mL of anhydrous CH 2 Cl 2 , ultrasonically disperse at room temp...

Embodiment 2

[0086] Embodiment 2, comparative example 1,2,4

[0087] 1. Sample preparation

[0088] (1) The preparation of the sample of Example 2 is carried out according to the following steps:

[0089] Step 1: Weigh mesoporous silica SBA15 (2.4g, pore diameter about 7.2nm, Langmuir specific surface area 556m2 / g), add methanol 40mL, ultrasonically disperse and wash at room temperature 25°C for 1 hour, and then centrifuge ( 9000rpm, 10min), repeat washing three times; add 40mL acetone, ultrasonically disperse at room temperature 25°C for 1 hour, centrifuge, and dry the washed product in a vacuum oven to powder.

[0090] Step 2: Transfer the powdered SBA15 to a 100mL clean schlenk bottle, add a magnetic stirrer, stopper the bottle with a rubber stopper, seal it with parafilm, vacuumize while heating, and continuously vacuum-dry at 250°C for 24 hours. Slowly open the nitrogen gas, cool the SBA15 to room temperature under nitrogen protection, and inject 50 mL of anhydrous CH 2 Cl 2 , ult...

Embodiment 3

[0115] Example 3, Comparative Examples 1-2,4

[0116] 1. Sample preparation

[0117] (1) The sample preparation of Example 3 is carried out according to the following steps:

[0118] Step 1: Weigh mesoporous silica SBA15 (2.4g, pore diameter about 7.2nm, Langmuir specific surface area 556m2 / g), add methanol 40mL, ultrasonically disperse and wash at room temperature 25°C for 1 hour, and then centrifuge ( 9000rpm, 10min), repeat washing three times; add 40mL acetone, ultrasonically disperse for 1 hour, centrifuge, and dry the washed product in a vacuum oven to powder.

[0119] Step 2: Transfer the powdered SBA15 to a 100mL clean schlenk bottle, add a magnetic stirrer, stopper the bottle with a rubber stopper, seal with parafilm, vacuumize while heating, and continuously vacuum-dry at 250°C for 24 hours. Slowly open the nitrogen gas, cool the SBA15 to room temperature under nitrogen protection, and inject 50 mL of anhydrous CH 2 Cl 2 , ultrasonically disperse at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com